模具专业英语

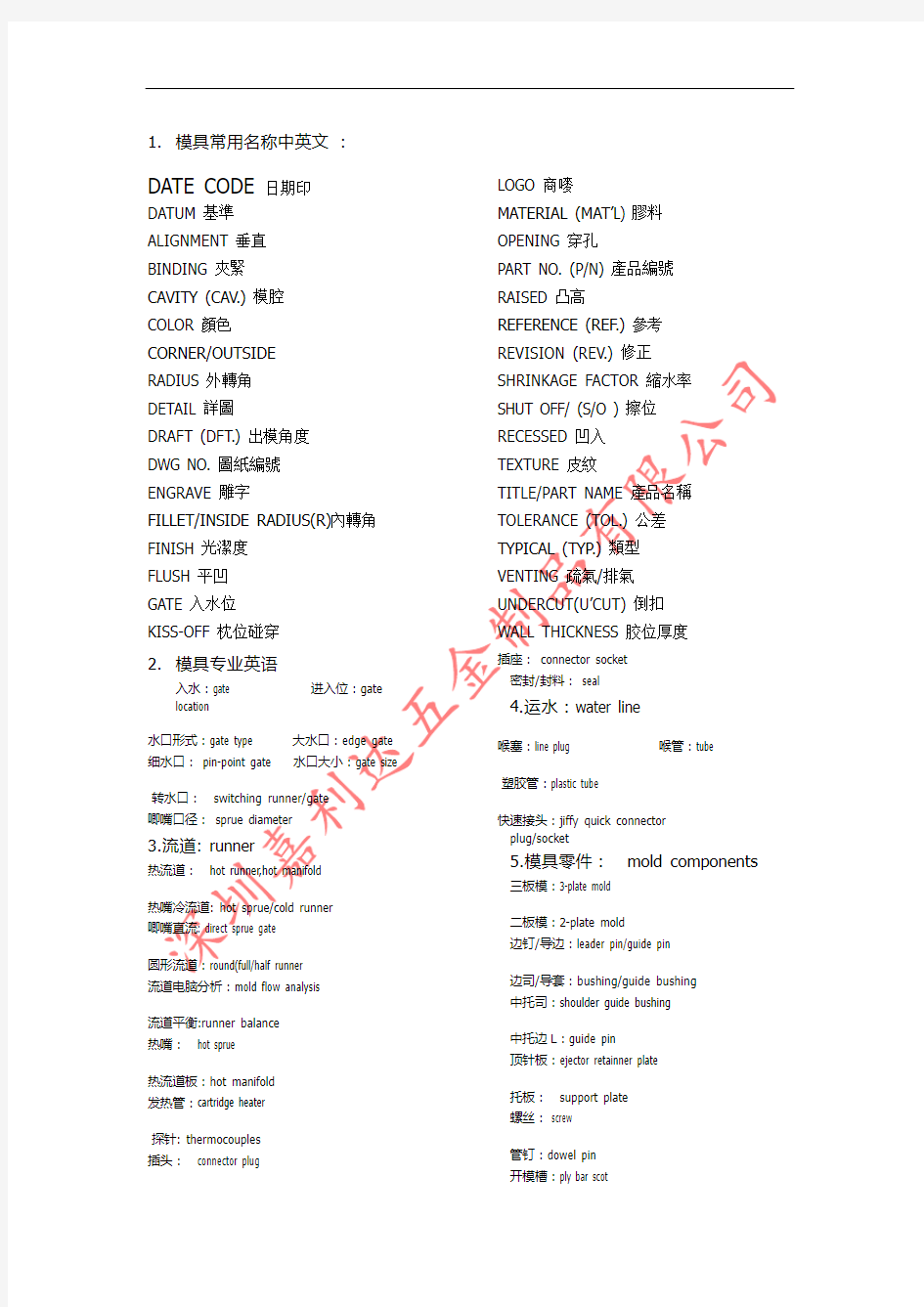

1.模具常用名称中英文:

DATE CODE 日期印DATUM 基準

ALIGNMENT 垂直

BINDING 夾緊

CAVITY (CAV.) 模腔

COLOR 顏色

CORNER/OUTSIDE

RADIUS 外轉角

DETAIL 詳圖

DRAFT (DFT.) 出模角度

DWG NO. 圖紙編號ENGRAVE 雕字

FILLET/INSIDE RADIUS(R)內轉角FINISH 光潔度

FLUSH 平凹

GATE 入水位

KISS-OFF 枕位碰穿LOGO 商嘜

MATERIAL (MAT’L) 膠料OPENING 穿孔

PART NO. (P/N) 產品編號RAISED 凸高REFERENCE (REF.) 參考REVISION (REV.) 修正SHRINKAGE FACTOR 縮水率SHUT OFF/ (S/O ) 擦位RECESSED 凹入TEXTURE 皮紋

TITLE/PART NAME 產品名稱TOLERANCE (TOL.) 公差TYPICAL (TYP.) 類型VENTING 疏氣/排氣UNDERCUT(U’CUT) 倒扣WALL THICKNESS 胶位厚度

2.模具专业英语

入水:gate 进入位:gate

location

水口形式:gate type 大水口:edge gate

细水口: pin-point gate 水口大小:gate size

转水口:switching runner/gate

唧嘴口径: sprue diameter

3.流道: runner

热流道:hot runner,hot manifold

热嘴冷流道: hot sprue/cold runner

唧嘴直流: direct sprue gate

圆形流道:round(full/half runner 流道电脑分析:mold flow analysis

流道平衡:runner balance

热嘴:hot sprue

热流道板:hot manifold

发热管:cartridge heater

探针: thermocouples

插头:connector plug 插座: connector socket

密封/封料: seal

4.运水:water line

喉塞:line plug 喉管:tube

塑胶管:plastic tube

快速接头:jiffy quick connector

plug/socket

5.模具零件:mold components 三板模:3-plate mold

二板模:2-plate mold

边钉/导边:leader pin/guide pin

边司/导套:bushing/guide bushing

中托司:shoulder guide bushing

中托边L:guide pin

顶针板:ejector retainner plate

托板:support plate

螺丝: screw

管钉:dowel pin

开模槽:ply bar scot

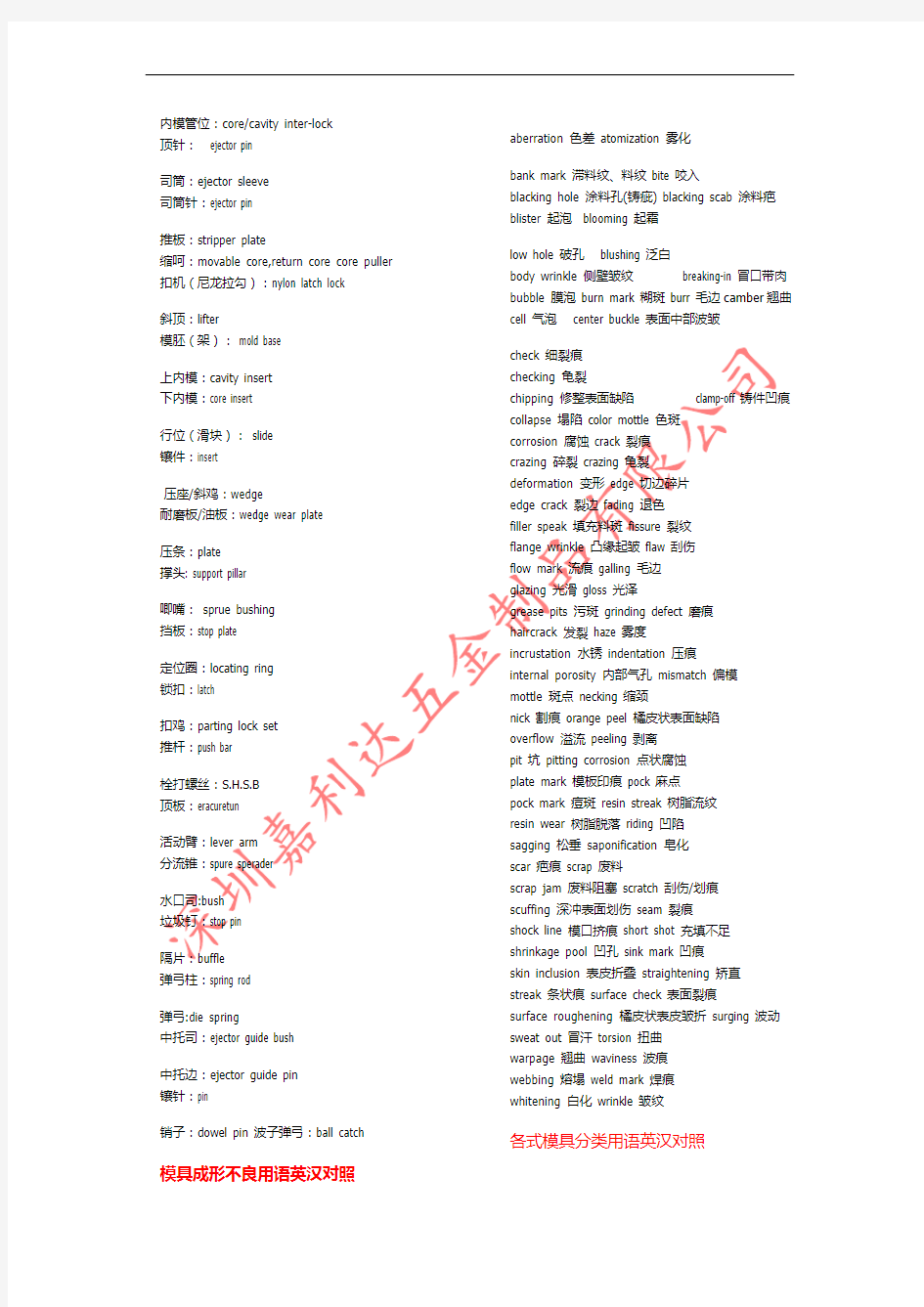

内模管位:core/cavity inter-lock

顶针:ejector pin

司筒:ejector sleeve

司筒针:ejector pin

推板:stripper plate

缩呵:movable core,return core core puller 扣机(尼龙拉勾):nylon latch lock

斜顶:lifter

模胚(架): mold base

上内模:cavity insert

下内模:core insert

行位(滑块): slide

镶件:insert

压座/斜鸡:wedge

耐磨板/油板:wedge wear plate

压条:plate

撑头: support pillar

唧嘴: sprue bushing

挡板:stop plate

定位圈:locating ring

锁扣:latch

扣鸡:parting lock set

推杆:push bar

栓打螺丝:S.H.S.B

顶板:eracuretun

活动臂:lever arm

分流锥:spure sperader

水口司:bush

垃圾钉:stop pin

隔片:buffle

弹弓柱:spring rod

弹弓:die spring

中托司:ejector guide bush

中托边:ejector guide pin

镶针:pin

销子:dowel pin 波子弹弓:

ball catch

模具成形不良用语英汉对照aberration 色差 atomization 雾化

bank mark 滞料纹、料纹 bite 咬入

blacking hole 涂料孔(铸疵) blacking scab 涂料疤blister 起泡 blooming 起霜

low hole 破孔 blushing 泛白

body wrinkle 侧壁皱纹 breaking-in 冒口带肉bubble 膜泡 burn mark 糊斑 burr 毛边camber翘曲cell 气泡 center buckle 表面中部波皱

check 细裂痕

checking 龟裂

chipping 修整表面缺陷 clamp-off 铸件凹痕collapse 塌陷 color mottle 色斑

corrosion 腐蚀 crack 裂痕

crazing 碎裂 crazing 龟裂

deformation 变形 edge 切边碎片

edge crack 裂边 fading 退色

filler speak 填充料斑 fissure 裂纹

flange wrinkle 凸缘起皱 flaw 刮伤

flow mark 流痕 galling 毛边

glazing 光滑 gloss 光泽

grease pits 污斑 grinding defect 磨痕

haircrack 发裂 haze 雾度

incrustation 水锈 indentation 压痕

internal porosity 内部气孔 mismatch 偏模

mottle 斑点 necking 缩颈

nick 割痕 orange peel 橘皮状表面缺陷

overflow 溢流 peeling 剥离

pit 坑 pitting corrosion 点状腐蚀

plate mark 模板印痕 pock 麻点

pock mark 痘斑 resin streak 树脂流纹

resin wear 树脂脱落 riding 凹陷

sagging 松垂 saponification 皂化

scar 疤痕 scrap 废料

scrap jam 废料阻塞 scratch 刮伤/划痕

scuffing 深冲表面划伤 seam 裂痕

shock line 模口挤痕 short shot 充填不足shrinkage pool 凹孔 sink mark 凹痕

skin inclusion 表皮折叠 straightening 矫直

streak 条状痕 surface check 表面裂痕

surface roughening 橘皮状表皮皱折 surging 波动sweat out 冒汗 torsion 扭曲

warpage 翘曲 waviness 波痕

webbing 熔塌 weld mark 焊痕

whitening 白化 wrinkle 皱纹

各式模具分类用语英汉对照

landed plunger mold 有肩柱塞式模具burnishing die 挤光模

landed positive mold 有肩全压式模具

button die 镶入式圆形凹模

loading shoe mold 料套式模具

center-gated mold 中心浇口式模具

loose detail mold 活零件模具

chill mold 冷硬用铸模 loose mold 活动式模具clod hobbing 冷挤压制模

louvering die 百叶窗冲切模

composite dies 复合模具 manifold die 分歧管模具counter punch 反凸模 modular mold 组合式模具double stack mold 双层模具

multi-cavity mold 多模穴模具

electroformed mold 电铸成形模

multi-gate mold 复式浇口模具

expander die 扩径模

offswt bending die 双折冷弯模具

extrusion die 挤出模 palletizing die 叠层模family mold 反套制品模具 plaster mold 石膏模blank through dies 漏件式落料模

porous mold 通气性模具

duplicated cavity plate 复板模

positive mold 全压式模具

fantail die 扇尾形模具 pressure die 压紧模fishtail die 鱼尾形模具 profile die 轮廓模

flash mold 溢料式模具 progressive die 顺序模gypsum mold 石膏铸模 protable mold 手提式模具hot-runner mold 热流道模具

prototype mold 雏形试验模具

ingot mold 钢锭模 punching die 落料模

lancing die 切口模

raising(embossing) 压花起伏成形

re-entrant mold 倒角式模具 sectional die 拼合模runless injection mold 无流道冷料模具

sectional die 对合模具

segment mold 组合模

semi-positive mold 半全压式模具

shaper 定型模套 single cavity mold 单腔模具solid forging die 整体锻模split forging die 拼合锻模

split mold 双并式模具

sprueless mold 无注道残料模具

squeezing die 挤压模 stretch form die 拉伸成形模sweeping mold 平刮铸模 swing die 振动模具three plates mold 三片式模具 trimming die 切边模unit mold 单元式模具 universal mold 通用模具unscrewing mold 退扣式模具 yoke type die 轭型模

各种模具常用成形方式英汉对照accurate die casting 精密压铸

powder forming 粉末成形

calendaring molding 压延成形

powder metal forging 粉末锻造

cold chamber die casting 冷式压铸

precision forging 精密锻造

cold forging 冷锻 press forging 冲锻compacting molding 粉末压出成形

rocking die forging 摇动锻造

compound molding 复合成形

rotary forging 回转锻造

compression molding 压缩成形

rotational molding 离心成形

dip mold 浸渍成形 rubber molding 橡胶成形encapsulation molding 注入成形

sand mold casting 砂模铸造

extrusion molding 挤出成形 shell casting 壳模铸造foam forming ?泡成形 sinter forging 烧结锻造forging roll 轧锻 six sides forging 六面锻造gravity casting 重力铸造 slush molding 凝塑成形hollow(blow) molding 中空(吹出)成形

squeeze casting 高压铸造

hot chamber die casting 热室压铸 swaging 挤锻hot forging 热锻 transfer molding 转送成形injection molding 射出成形 warm forging 温锻investment casting 精密铸造

matched die method 对模成形法

laminating method 被覆淋膜成形

low pressure casting 低压铸造

lost wax casting 脱蜡铸造

matched mould thermal forming 对模热成形模

机械类常用英语:冲压模具-零件类

punch冲头

insert入块(嵌入件)

deburring punch压毛边冲子

groove punch压线冲子

stamped punch字模冲子

round punch圆冲子

special shape punch异形冲子

bending block折刀

roller滚轴

baffle plate挡块

located block定位块

supporting block for location

定位支承块

air cushion plate气垫板

air-cushion eject-rod气垫顶杆

trimming punch切边冲子

stiffening rib punch = stinger 加强筋冲子ribbon punch压筋冲子

reel-stretch punch卷圆压平冲子

guide plate定位板

sliding block滑块

sliding dowel block滑块固定块

active plate活动板

lower sliding plate下滑块板

upper holder block上压块

upper mid plate上中间板

spring box弹簧箱

spring-box eject-rod弹簧箱顶杆

spring-box eject-plate弹簧箱顶板

bushing bolck衬套

cover plate盖板

guide pad导料块

机械类常用英语:冲压模具-模板类top plate上托板(顶板)

top block上垫脚

punch set上模座

punch pad上垫板

punch holder上夹板

stripper pad脱料背板

up stripper上脱料板

male die公模(凸模)

feature die公母模

female die母模(凹模)

upper plate上模板

lower plate下模板

die pad下垫板die holder下夹板

die set下模座

bottom block下垫脚

bottom plate下托板(底板)

stripping plate内外打(脱料板)

outer stripper外脱料板

inner stripper内脱料板

lower stripper下脱料板

冲压模具-冲压名称类英汉对照

plain die简易模

pierce die冲孔模

forming die成型模

progressive die连续模

gang dies复合模

shearing die剪边模

riveting die铆合模

pierce冲孔

forming成型(抽凸,冲凸)

draw hole抽孔

bending折弯

trim切边

emboss凸点

dome凸圆

semi-shearing半剪

stamp mark冲记号

deburr or coin压毛边

punch riveting冲压铆合

side stretch侧冲压平

reel stretch卷圆压平

groove压线

blanking下料

stamp letter冲字(料号)

shearing剪断

tick-mark nearside正面压印

tick-mark farside反面压印

extension dwg展开图

procedure dwg工程图

die structure dwg模具结构图

material材质

material thickness料片厚度

factor系数

upward向上

downward向下

press specification冲床规格

die height range适用模高

die height闭模高度

burr毛边 gap间隙 weight重量 total wt.总重量punch wt.上模重量

high-speed transmission高速传递heat dissipation热传

rack上料

degrease脱脂

rinse水洗

alkaline etch龄咬

desmut剥黑膜

D.I. rinse纯水次

Chromate铬酸处理

Anodize阳性处理

seal封孔

revision版次

part number/P/N料号

good products良品

scraped products报放心品defective products不良品finished products成品

disposed products处理品barcode条码

flow chart流程表单

assembly组装

stamping冲压

molding成型

spare parts=buffer备品coordinate座标

dismantle the die折模

auxiliary fuction辅助功能

poly-line多义线

heater band 加热片thermocouple热电偶

sand blasting喷沙

grit 砂砾

derusting machine除锈机

degate打浇口

dryer烘干机

induction感应

induction light感应光

response=reaction=interaction感应ram连杆

edge finder巡边器

concave凸

convex凹

short射料不足

nick缺口

speck瑕??

shine亮班

splay 银纹

gas mark焦痕

delamination起鳞

cold slug冷块blush 导色

gouge沟槽;凿槽

satin texture段面咬花

witness line证示线

patent专利

grit沙砾

granule=peuet=grain细粒

grit maker抽粒机

cushion缓冲

magnalium镁铝合金

magnesium镁金

metal plate钣金

lathe车

mill锉

plane刨

grind磨

drill铝

boring镗

blinster气泡

fillet镶;嵌边

through-hole form通孔形式

voller pin formality滚针形式

cam driver铡楔

shank摸柄

crank shaft曲柄轴

augular offset角度偏差

velocity速度

production tempo生产进度现状

torque扭矩

spline=the multiple keys花键

quenching淬火

tempering回火

annealing退火

carbonization碳化

alloy合金

tungsten high speed steel钨高速的

moly high speed steel钼高速的

organic solvent有机溶剂

bracket小磁导

liaison联络单

volatile挥发性

resistance电阻

ion离子

titrator滴定仪

beacon警示灯

coolant冷却液

crusher破碎机

模具工程常用词汇英汉对照——2 stock age analysis sheet

库存货龄分析表

on-hand inventory现有库存

available material良品可使用

obsolete material良品已呆滞

to be inspected or reworked

待验或重工

total合计

cause description原因说明

part number/ P/N 料号

type形态

item/group/class类别

quality品质

prepared by制表

notes说明

year-end physical inventory difference analysis sheet

年终盘点差异分析表

physical inventory盘点数量

physical count quantity帐面数量

difference quantity差异量

cause analysis原因分析

raw materials原料

materials物料

finished product成品

semi-finished product半成品

packing materials包材

good product/accepted goods/ accepted parts/good parts良品

defective product/non-good parts不良品disposed goods处理品

warehouse/hub仓库

on way location在途仓

oversea location海外仓

spare parts physical inventory list备品盘点清单spare molds location模具备品仓

skid/pallet栈板

tox machine自铆机

wire EDM线割

EDM放电机

coil stock卷料

sheet stock片料

tolerance工差

score=groove压线

cam block滑块

pilot导正筒

trim剪外边

pierce剪内边

drag form压锻差

pocket for the punch head挂钩槽

slug hole废料孔

feature die公母模

expansion dwg展开图radius半径

shim(wedge)楔子

torch-flame cut火焰切割

set screw止付螺丝

form block折刀

stop pin定位销

round pierce punch=die button圆冲子shape punch=die insert异形子

stock locater block定位块

under cut=scrap chopper清角active plate活动板

baffle plate挡块

cover plate盖板

male die公模

female die母模

groove punch压线冲子

air-cushion eject-rod气垫顶杆spring-box eject-plate弹簧箱顶板bushing block衬套

insert 入块

club car高尔夫球车

capability能力

parameter参数

factor系数

phosphate皮膜化成

viscosity涂料粘度

alkalidipping脱脂

main manifold主集流脉

bezel斜视规

blanking穿落模

dejecting顶固模demagnetization去磁;消磁

模具工程常用词汇英汉对照

die 模具

figure file, chart file图档

cutting die, blanking die冲裁模progressive die, follow (-on)die

连续模

compound die复合模

punched hole冲孔

panel board镶块

to cutedges=side cut=side scrap切边to bending折弯

to pull, to stretch拉伸

Line streching, line pulling线拉伸engraving, to engrave刻印upsiding down edges翻边

to stake铆合

designing, to design设计

design modification设计变化

die block模块

folded block折弯块

sliding block滑块

location pin定位销

lifting pin顶料销

die plate, front board模板

padding block垫块

stepping bar垫条

upper die base上模座

lower die base下模座

upper supporting blank上承板

upper padding plate blank上垫板

spare dies模具备品

spring 弹簧

bolt螺栓

document folder文件夹

file folder资料夹

to put file in order整理资料

spare tools location手工备品仓

first count初盘人

first check初盘复棹人

second count 复盘人

second check复盘复核人

equipment设备

waste materials废料

work in progress product在制品

casing = containerazation装箱

quantity of physical invetory second count 复盘点数量

quantity of customs count

会计师盘,点数量

the first page第一联

filed by accounting department for reference会计部存查

end-user/using unit(department)使用单位summary of year-end physical inventory bills

年终盘点截止单据汇总表

bill name单据名称

This sheet and physical inventory list will be sent to accounting

department together (Those of NHK will be sent to financial

department)

本表请与盘点清册一起送会计部-(NHK厂区送财会部)

Application status records of year-end physical inventory List and

physical inventory card 年终盘点卡与清册使用-状况明细表

blank and waste sheet NO.

空白与作废单号

plate电镀mold成型

material for engineering mold testing工程试模材料not included in physical inventory不列入盘点sample样品

incoming material to be inspected进货待验description品名

steel/rolled steel钢材

material statistics sheet

物料统计明细表

meeting minutes会议记录

meeting type 会别

distribution department分发单位

location地点

chairman主席

present members出席人员

subject主题

conclusion结论

decision items决议事项

responsible department负责单位

pre-fixed finishing date预定完成日

approved by / checked by / prepared by核准/审核/承办

PCE assembly production schedule sheet

PCE组装厂生产排配表

model机锺

work order工令

revision版次

remark备注

production control confirmation生产确认checked by初审

approved by核准

department部门

模具钢材及零件英语

模具钢材

alloy tool steel 合金工具钢

aluminium alloy 铝合金钢

bearing alloy 轴承合金

blister steel 浸碳钢

bonderized steel sheet 邦德防蚀钢板

carbon tool steel 碳素工具钢

clad sheet 被覆板

clod work die steel 冷锻模用钢

emery 金钢砂

ferrostatic pressure 钢铁水静压力

forging die steel 锻造模用钢

galvanized steel sheet 镀锌铁板

hard alloy steel 超硬合金钢

high speed tool steel 高速度工具钢

hot work die steel 热锻模用钢

low alloy tool steel 特殊工具钢

low manganese casting steel 低锰铸钢marging steel 马式体高强度热处理钢martrix alloy 马特里斯合金

meehanite cast iron 米汉纳铸钢meehanite metal 米汉纳铁

merchant iron 市售钢材

molybdenum high speed steel 钼系高速钢molybdenum steel 钼钢

nickel chromium steel 镍铬钢prehardened steel 顶硬钢

silicon steel sheet 硅钢板

stainless steel 不锈钢

tin plated steel sheet 镀锡铁板

tough pitch copper 韧铜

troostite 吐粒散铁

tungsten steel 钨钢

vinyl tapped steel sheet 塑料覆面钢板

零件英语

punch冲头

insert入块(嵌入件)

deburring punch压毛边冲子

groove punch压线冲子

stamped punch字模冲子

round punch圆冲子

special shape punch异形冲子

bending block折刀

roller滚轴

baffle plate挡块

located block定位块

supporting block for location 定位支承块air cushion plate气垫板

air-cushion eject-rod气垫顶杆trimming punch切边冲子

stiffening rib punch = stinger 加强筋冲子ribbon punch压筋冲子

reel-stretch punch卷圆压平冲子

guide plate定位板

sliding block滑块

sliding dowel block滑块固定块

active plate活动板

lower sliding plate下滑块板

upper holder block上压块

upper mid plate上中间板

spring box弹簧箱

spring-box eject-rod弹簧箱顶杆

spring-box eject-plate弹簧箱顶板bushing bolck衬套

cover plate盖板

guide pad导料块塑件&模具相关英文

compre sion molding压缩成型

flash mold溢流式模具

plsitive mold挤压式模具

split mold分割式模具

cavity型控母模

core模心公模

taper锥拔

leather cloak仿皮革

shiver饰纹

flow mark流痕

welding mark溶合痕

post screw insert螺纹套筒埋值

self tapping screw自攻螺丝

striper plate脱料板

piston活塞

cylinder汽缸套

chip细碎物

handle mold手持式模具移转成型用模具encapsulation molding低压封装成型射出成型用模具two plate两极式(模具)

well type蓄料井

insulated runner绝缘浇道方式

hot runner热浇道

runner plat浇道模块

valve gate阀门浇口

band heater环带状的电热器

spindle阀针

spear head刨尖头

slag well冷料井

cold slag冷料渣

air vent排气道

h=0.02~0.05mm

w=3.2mm

L=3~5mm

welding line熔合痕

eject pin顶出针

knock pin顶出销

return pin回位销反顶针

sleave套筒

stripper plate脱料板

insert core放置入子

runner stripper plate浇道脱料板

guide pin导销

eject rod (bar)(成型机)顶业捧

subzero深冷处理

three plate三极式模具

runner system浇道系统

stress crack应力电裂

orientation定向

sprue gate射料浇口,直浇口

nozzle射嘴 slag well冷料井 side gate侧浇口

edge gate侧缘浇口 tab gate搭接浇口

film gate薄膜浇口 flash gate闸门浇口

slit gate缝隙浇口 fan gate扇形浇口

dish gate因盘形浇口 H=F=1/2t~1/5t

T=2.5~3.5mm

diaphragm gate隔膜浇口 ring gate环形浇口subarine gate潜入式浇口 tunnel gate隧道式浇口pin gate针点浇口Φ0.8~1.0mm

Runner less无浇道 (sprue less)无射料管方式long nozzle延长喷嘴方式 sprue浇口; 溶渣 sprue lock pin料头钩销(拉料杆)

eject pin顶出针

knock pin顶出销

return pin回位销反顶针

sleave套筒

stripper plate脱料板

insert core放置入子

runner stripper plate浇道脱料板

guide pin导销

eject rod (bar)(成型机)顶业捧

subzero深冷处理

three plate三极式模具

runner system浇道系统

stress crack应力电裂

orientation定向

sprue gate射料浇口,直浇口

nozzle射嘴

sprue lock pin料头钩销(拉料杆)

slag well冷料井

side gate侧浇口

edge gate侧缘浇口

tab gate搭接浇口

film gate薄膜浇口

flash gate闸门浇口

slit gate缝隙浇口

fan gate扇形浇口

dish gate因盘形浇口

diaphragm gate隔膜浇口

ring gate环形浇口subarine gate潜入式浇口

tunnel gate隧道式浇口

pin gate针点浇口

Runner less无浇道

(sprue less)无射料管方式

long nozzle延长喷嘴方式

sprue浇口;溶渣

塑件模具相关英文——9

compre sion molding压缩成型

flash mold溢流式模具

plsitive mold挤压式模具

split mold分割式模具

cavity型控母模

core模心公模

taper锥拔

leather cloak仿皮革

shiver饰纹

flow mark流痕

welding mark溶合痕

post screw insert螺纹套筒埋值

self tapping screw自攻螺丝

striper plate脱料板

piston活塞

cylinder汽缸套

chip细碎物

handle mold手持式模具

encapsulation molding低压封装成型、射出成型用模具

two plate两极式(模具)

well type蓄料井

insulated runner绝缘浇道方式

hot runner热浇道

runner plat浇道模块

valve gate阀门浇口

band heater环带状的电热器spindle阀针

spear head刨尖头

slag well冷料井

cold slag冷料渣

air vent排气道

welding line熔合痕

模具相关英语——8 stop screw止付螺丝

located pin定位销

outer bush外导套

模板类

top plate上托板(顶板)

top block上垫脚

punch set上模座

punch pad上垫板

punch holder上夹板

stripper pad脱料背板

up stripper上脱料板

male die公模(凸模)

feature die公母模

female die母模(凹模)

upper plate上模板

lower plate下模板

die pad下垫板

die holder下夹板

die set下模座

bottom block下垫脚

bottom plate下托板(底板) stripping plate内外打(脱料板) outer stripper外脱料板

inner stripper内脱料板

lower stripper下脱料板

零件类

punch冲头

insert入块(嵌入件) deburring punch压毛边冲子groove punch压线冲子stamped punch字模冲子

round punch圆冲子

special shape punch异形冲子

bending block折刀

roller滚轴

baffle plate挡块

located block定位块

supporting block for location

定位支承块

air cushion plate气垫板

air-cushion eject-rod气垫顶杆trimming punch切边冲子

stiffening rib punch = stinger 加强筋冲子ribbon punch压筋冲子

reel-stretch punch卷圆压平冲子

guide plate定位板

sliding block滑块

模具相关英语——7 emboss凸点

dome凸圆

semi-shearing半剪

stamp mark冲记号

deburr or coin压毛边

punch riveting冲压铆合

side stretch侧冲压平

reel stretch卷圆压平

groove压线

blanking下料

stamp letter冲字(料号)

shearing剪断

tick-mark nearside正面压印

tick-mark farside反面压印

冲压名称类

extension dwg展开图

procedure dwg工程图

die structure dwg模具结构图

material材质

material thickness料片厚度factor系数

upward向上

downward向下

press specification冲床规格

die height range适用模高

die height闭模高度

burr毛边

gap间隙

weight重量

total wt.总重量

punch wt.上模重量

五金零件类

inner guiding post内导柱

inner hexagon screw内六角螺钉dowel pin固定销

coil spring弹簧

lifter pin顶料销

eq-height sleeves=spool等高套筒pin销

lifter guide pin浮升导料销guide pin导正销

wire spring圆线弹簧

outer guiding post外导柱

模具相关英语——6

drill钻

boring镗

blinster气泡

fillet镶;嵌边

through-hole form通孔形式voller pin formality滚针形式cam driver铡楔

shank摸柄

crank shaft曲柄轴

augular offset角度偏差

velocity速度

production tempo生产进度现状torque扭矩

spline=the multiple keys花键quenching淬火

tempering回火

annealing退火

carbonization碳化

alloy合金

tungsten high speed steel钨高速的moly high speed steel钼高速的organic solvent有机溶剂

bracket小磁导

liaison联络单

volatile挥发性

resistance电阻

ion离子

titrator滴定仪

beacon警示灯

coolant冷却液

crusher破碎机

模具工程类

plain die简易模

pierce die冲孔模

forming die成型模

progressive die连续模

gang dies复合模

shearing die剪边模

riveting die铆合模

pierce冲孔

forming成型(抽凸,冲凸)

draw hole抽孔

bending折弯

trim切边

模具相关英语——5

spare parts=buffer备品coordinate坐标

dismantle the die折模

auxiliary fuction辅助功能

poly-line多义线

heater band 加热片thermocouple热电偶

sand blasting喷沙

grit 砂砾

derusting machine除锈机

degate打浇口

dryer烘干机

induction感应

induction light感应光

response=reaction=interaction感应ram连杆

edge finder巡边器

concave 凹

convex凸

short射料不足

nick缺口

speck瑕疪

shine亮班

splay 银纹

gas mark焦痕

delamination起鳞

cold slug冷块

blush 导色

gouge沟槽;凿槽

satin texture段面咬花

witness line证示线

patent专利

grit沙砾

granule=peuet=grain细粒

grit maker抽粒机

cushion缓冲

magnalium镁铝合金magnesium镁金

metal plate钣金

lathe车

mill锉

plane刨

grind磨模具相关英语——4 baffle plate挡块

cover plate盖板

male die公模

female die母模

groove punch压线冲子

air-cushion eject-rod气垫顶杆spring-box eject-plate弹簧箱顶板bushing block衬套

insert 入块

club car高尔夫球车

capability能力

parameter参数

factor系数

phosphate皮膜化成

viscosity涂料粘度alkalidipping脱脂

main manifold主集流脉

bezel斜视规

blanking穿落模

dejecting顶固模demagnetization去磁;消磁

high-speed transmission高速传递heat dissipation热传

rack上料

degrease脱脂

rinse水洗

alkaline etch龄咬

desmut剥黑膜

D.I. rinse纯水次

Chromate铬酸处理

Anodize阳性处理

seal封孔

revision版次

part number/P/N料号

good products良品

scraped products报放心品defective products不良品

finished products成品

disposed products处理品

barcode条形码

flow chart流程窗体

assembly组装

stamping冲压

molding成型

模具相关英语——3

difference quantity差异量

cause analysis原因分析

raw materials原料

materials物料

finished product成品

semi-finished product半成品

packing materials包材

good product/accepted goods/ accepted parts/good parts良品

defective product/non-good parts不良品disposed goods处理品

warehouse/hub仓库

on way location在途仓

oversea location海外仓

spare parts physical inventory list备品盘点清单spare molds location模具备品仓

skid/pallet栈板

tox machine自铆机

wire EDM线割

EDM放电机

coil stock卷料

sheet stock片料

tolerance工差

score=groove压线

cam block滑块

pilot导正筒

trim剪外边

pierce剪内边

drag form压锻差pocket for the punch head挂钩槽

slug hole废料孔

feature die公母模

expansion dwg展开图

radius半径

shim(wedge)楔子

torch-flame cut火焰切割

set screw止付螺丝

form block折刀

stop pin定位销

round pierce punch=die button圆冲子

shape punch=die insert异形子

stock locater block定位块

under cut=scrap chopper清角

active plate活动板

模具相关英语——2

steel/rolled steel钢材

material statistics sheet

物料统计明细表

meeting minutes会议记录

meeting type 会别

distribution department分发单位

location地点

chairman主席

present members出席人员

subject主题

conclusion结论

decision items决议事项

responsible department负责单位

pre-fixed finishing date预定完成日

approved by / checked by / prepared by核准/审核/承办

PCE assembly production schedule sheet

PCE组装厂生产排配表

model机钟

work order工令

revision版次

remark备注

production control confirmation生产确认

checked by初审

approved by核准

department部门

stock age analysis sheet

库存货龄分析表

on-hand inventory现有库存

available material良品可使用

obsolete material良品已呆滞

to be inspected or reworked

待验或重工

total合计

cause description原因说明

part number/ P/N 料号

type形态

item/group/class类别

quality品质

prepared by制表

notes说明

year-end physical inventory difference analysis sheet 年终盘点差异分析表

physical inventory盘点数量

physical count quantity帐面数量

模具相关英语——1

padding block垫块

stepping bar垫条

upper die base上模座

lower die base下模座

upper supporting blank上承板

upper padding plate blank上垫板

spare dies模具备品

spring 弹簧

bolt螺栓

document folder活页夹file folder资料夹

to put file in order整理资料

spare tools location手工备品仓

first count初盘人

first check初盘复棹人

second count 复盘人

second check复盘复核人

equipment设备

waste materials废料

work in progress product在制品

casing = containerazation装箱

quantity of physical invetory second count 复盘点数

量

quantity of customs count

会计师盘,点数量

the first page第一联

filed by accounting department for reference会计部

存查

end-user/using unit(department)使用单位

summary of year-end physical inventory bills

年终盘点截止单据汇总表

bill name单据名称

This sheet and physical inventory list will be sent to accounting department

together (Those of NHK will be sent to financial department)

本表请与盘点清册一起送会计部-(NHK厂区送财会部) Application status records of year-end physical inventory List and physical

inventory card 年终盘点卡与清册使用-状况明细表blank and waste sheet NO.

空白与作废单号

plate电镀

mold成型

material for engineering mold testing工程试模材料

not included in physical inventory不列入盘点

sample样品

incoming material to be inspected进货待验description品名

101个热处理常用英文词汇

1. indication 缺陷

2. test specimen 试样

3. bar 棒材

4. stock 原料

5. billet 方钢,钢方坯

6. bloom 钢坯,钢锭

7. section 型材

8. steel ingot 钢锭

9. blank 坯料,半成品

10. cast steel 铸钢

11. nodular cast iron 球墨铸铁

12. ductile cast iron 球墨铸铁

13. bronze 青铜

14. brass 黄铜

15. copper 合金

16. stainless steel不锈钢

17. decarburization 脱碳

18. scale 氧化皮

19. anneal 退火

20. process anneal 进行退火

21. quenching 淬火

22. normalizing 正火

23. Charpy impact text 夏比冲击试验

24. fatigue 疲劳

25. tensile testing 拉伸试验

26. solution 固溶处理

27. aging 时效处理

28. Vickers hardness维氏硬度

29. Rockwell hardness 洛氏硬度

30. Brinell hardness 布氏硬度

31. hardness tester硬度计

32. descale 除污,除氧化皮等

33. ferrite 铁素体

34. austenite 奥氏体

35. martensite马氏体

36. cementite 渗碳体

37. iron carbide 渗碳体

38. solid solution 固溶体

39. sorbite 索氏体

40. bainite 贝氏体

41. pearlite 珠光体

42. nodular fine pearlite/ troostite屈氏体

43. black oxide coating 发黑

44. grain 晶粒

45. chromium 铬

46. cadmium 镉47. tungsten 钨

48. molybdenum 钼

49. manganese 锰

50. vanadium 钒

51. molybdenum 钼

52. silicon 硅

53. sulfer/sulphur 硫

54. phosphor/ phosphorus 磷

55. nitrided 氮化的

56. case hardening 表面硬化,表面淬硬

57. air cooling 空冷

58. furnace cooling 炉冷

59. oil cooling 油冷

60. electrocladding /plating 电镀

61. brittleness 脆性

62. strength 强度

63. rigidity 刚性,刚度

64. creep 蠕变

65. deflection 挠度

66. elongation 延伸率

67. yield strength 屈服强度

68. elastoplasticity 弹塑性

69. metallographic structure 金相组织

70. metallographic test 金相试验

71. carbon content 含碳量

72. induction hardening 感应淬火

73. impedance matching 感应淬火

74. hardening and tempering 调质

75. crack 裂纹

76. shrinkage 缩孔,疏松

77. forging 锻(件)

78. casting 铸(件)

79. rolling 轧(件)

80. drawing 拉(件)

81. shot blasting 喷丸(处理)

82. grit blasting 喷钢砂(处理)

83. sand blasting 喷砂(处理)

84. carburizing 渗碳

85. nitriding 渗氮

86. ageing/aging 时效

87. grain size 晶粒度

88. pore 气孔

89. sonim 夹砂

90. cinder inclusion 夹渣

91. lattice晶格

92. abrasion/abrasive/rub/wear/wearing resistance (property) 耐磨性

93. spectrum analysis光谱分析

94. heat/thermal treatment 热处理

95. inclusion 夹杂物

96. segregation 偏析

97. picking 酸洗,酸浸

98. residual stress 残余应力

99. remaining stress 残余应力

100. relaxation of residual stress 消除残余应力101. stress relief 应力释放

模具相关英语(5)

semi-shearing半剪

stamp mark冲记号

deburr or coin压毛边

punch riveting冲压铆合

side stretch侧冲压平

reel stretch卷圆压平

groove压线

blanking下料

stamp letter冲字(料号)

shearing剪断

tick-mark nearside正面压印

tick-mark farside反面压印

冲压名称类

extension dwg展开图

procedure dwg工程图

die structure dwg模具结构图

material材质

material thickness料片厚度

factor系数

upward向上

downward向下

press specification冲床规格

die height range适用模高

die height闭模高度

burr毛边

gap间隙

weight重量

total wt.总重量

punch wt.上模重量

五金零件类

inner guiding post内导柱

inner hexagon screw内六角螺钉

dowel pin固定销

coil spring弹簧

lifter pin顶料销

eq-height sleeves=spool等高套筒

pin销

lifter guide pin浮升导料销

guide pin导正销

wire spring圆线弹簧

outer guiding post外导柱

stop screw止付螺丝

located pin定位销

outer bush外导套模板类

top plate上托板(顶板)

top block上垫脚

punch set上模座

punch pad上垫板

punch holder上夹板

stripper pad脱料背板

up stripper上脱料板

male die公模(凸模)

feature die公母模

female die母模(凹模)

upper plate上模板

lower plate下模板

die pad下垫板

die holder下夹板

die set下模座

bottom block下垫脚

bottom plate下托板(底板)

stripping plate内外打(脱料板)

outer stripper外脱料板

inner stripper内脱料板

lower stripper下脱料板

零件类

punch冲头

insert入块(嵌入件)

deburring punch压毛边冲子

groove punch压线冲子

stamped punch字模冲子

round punch圆冲子

special shape punch异形冲子

bending block折刀

roller滚轴

baffle plate挡块

located block定位块

supporting block for location

定位支承块

air cushion plate气垫板

air-cushion eject-rod气垫顶杆trimming punch切边冲子

stiffening rib punch = stinger 加强筋冲子ribbon punch压筋冲子

reel-stretch punch卷圆压平冲子

guide plate定位板

sliding block滑块

模具相关英语(4)

coordinate坐标

dismantle the die折模

auxiliary fuction辅助功能

poly-line多义线

heater band 加热片thermocouple热电偶

sand blasting喷沙

grit 砂砾

derusting machine除锈机

degate打浇口

dryer烘干机

induction感应

induction light感应光

response=reaction=interaction感应ram连杆

edge finder巡边器

concave 凹

convex凸

short射料不足

nick缺口

speck瑕疪

shine亮班

splay 银纹

gas mark焦痕

delamination起鳞

cold slug冷块

blush 导色

gouge沟槽;凿槽

satin texture段面咬花

witness line证示线

patent专利

grit沙砾

granule=peuet=grain细粒

grit maker抽粒机

cushion缓冲

magnalium镁铝合金magnesium镁金

metal plate钣金

lathe车

mill锉

plane刨

grind磨

drill钻

boring镗

blinster气泡

fillet镶;嵌边

through-hole form通孔形式

voller pin formality滚针形式

cam driver铡楔

shank摸柄

crank shaft曲柄轴

augular offset角度偏差

velocity速度

production tempo生产进度现状torque扭矩

spline=the multiple keys花键quenching淬火

tempering回火

annealing退火

carbonization碳化

alloy合金

tungsten high speed steel钨高速的moly high speed steel钼高速的organic solvent有机溶剂

bracket小磁导

liaison联络单

volatile挥发性

resistance电阻

ion离子

titrator滴定仪

beacon警示灯

coolant冷却液

crusher破碎机

模具工程类

plain die简易模

pierce die冲孔模

forming die成型模

progressive die连续模

gang dies复合模

shearing die剪边模

riveting die铆合模

pierce冲孔

forming成型(抽凸,冲凸)

draw hole抽孔

bending折弯

trim切边

emboss凸点

dome凸圆

模具相关英语(3)

difference quantity差异量

cause analysis原因分析

raw materials原料

materials物料

finished product成品

semi-finished product半成品

packing materials包材

good product/accepted goods/ accepted parts/good parts良品

defective product/non-good parts不良品disposed goods处理品

warehouse/hub仓库

on way location在途仓

oversea location海外仓

spare parts physical inventory list备品盘点清单spare molds location模具备品仓

skid/pallet栈板

tox machine自铆机

wire EDM线割

EDM放电机

coil stock卷料

sheet stock片料

tolerance工差

score=groove压线

cam block滑块

pilot导正筒

trim剪外边

pierce剪内边

drag form压锻差

pocket for the punch head挂钩槽

slug hole废料孔

feature die公母模

expansion dwg展开图

radius半径

shim(wedge)楔子

torch-flame cut火焰切割

set screw止付螺丝

form block折刀

stop pin定位销

round pierce punch=die button圆冲子

shape punch=die insert异形子

stock locater block定位块

under cut=scrap chopper清角

active plate活动板

baffle plate挡块

cover plate盖板

male die公模

female die母模

groove punch压线冲子

air-cushion eject-rod气垫顶杆

spring-box eject-plate弹簧箱顶板

bushing block衬套

insert 入块

club car高尔夫球车

capability能力

parameter参数

factor系数

phosphate皮膜化成

viscosity涂料粘度

alkalidipping脱脂

main manifold主集流脉

bezel斜视规

blanking穿落模

dejecting顶固模demagnetization去磁;消磁

high-speed transmission高速传递

heat dissipation热传

rack上料

degrease脱脂

rinse水洗

alkaline etch龄咬

desmut剥黑膜

D.I. rinse纯水次

Chromate铬酸处理

Anodize阳性处理

seal封孔

revision版次

part number/P/N料号

good products良品

scraped products报放心品

defective products不良品

finished products成品

disposed products处理品

barcode条形码

flow chart流程窗体

assembly组装

stamping冲压

molding成型

spare parts=buffer备品

模具相关英语(2)

material for engineering mold testing工程试模材料not included in physical inventory不列入盘点sample样品

incoming material to be inspected进货待验description品名

steel/rolled steel钢材

material statistics sheet

物料统计明细表

meeting minutes会议记录

meeting type 会别

distribution department分发单位

location地点

chairman主席

present members出席人员

subject主题

conclusion结论

decision items决议事项

responsible department负责单位

pre-fixed finishing date预定完成日

approved by / checked by / prepared by核准/审核/承办

PCE assembly production schedule sheet

PCE组装厂生产排配表

model机钟

work order工令

revision版次

remark备注

production control confirmation生产确认checked by初审

approved by核准

department部门

stock age analysis sheet

库存货龄分析表

on-hand inventory现有库存

available material良品可使用

obsolete material良品已呆滞

to be inspected or reworked

待验或重工

total合计

cause description原因说明

part number/ P/N 料号

type形态

item/group/class类别

quality品质

prepared by制表

notes说明

year-end physical inventory difference analysis sheet

年终盘点差异分析表

physical inventory盘点数量

physical count quantity帐面数量

模具相关英语(1)

padding block垫块

stepping bar垫条

upper die base上模座

lower die base下模座

upper supporting blank上承板

upper padding plate blank上垫板

spare dies模具备品

spring 弹簧

bolt螺栓

document folder活页夹

file folder资料夹

to put file in order整理资料

spare tools location手工备品仓

first count初盘人

first check初盘复棹人

second count 复盘人

second check复盘复核人

equipment设备

waste materials废料

work in progress product在制品

casing = containerazation装箱

quantity of physical invetory second count 复盘点数量

quantity of customs count

会计师盘,点数量the first page第一联

filed by accounting department for reference会计部存查

end-user/using unit(department)使用单位summary of year-end physical inventory bills

年终盘点截止单据汇总表

bill name单据名称

This sheet and physical inventory list will be sent to accounting department

together (Those of NHK will be sent to financial department)

本表请与盘点清册一起送会计部-(NHK厂区送财会部)

Application status records of year-end physical inventory List and physical

inventory card 年终盘点卡与清册使用-状况明细表blank and waste sheet NO.

空白与作废单号

plate电镀

mold成型

注塑模部分中英文对照

塑料成形模具 mould for plastics

热塑性塑料模 mould for thermoplastics

热固性塑料模 mould for thermosets

压缩模 compression mould

压注模、传递模 transfer mould

注射模 injection mould

热塑性塑料注射模 injection mould for thermoplastics

热固性塑料注射模 injection mould for thermoses

成形零件

定模 stationary mould fixed half

动模 movable mould moving half

定模座板 fixed clamp plate, top clamping plate. top plate

动模座板 moving clamp plate. bottom clamping plate. bottom plate

上模座板 upper clamping plate

下模座板 lower clamping plate

凹模固定板 cavity-retainer plate

型芯固定板 core-retainer plate

凸模固定板 punch-retainer plate

模套 chase. bolster. frame

支承板 backing plate. supprr plate

垫块 spacer parallel

支架 ejector housing. mould base leg

动模 movable mould moving half

定模座板 fixed clamp plate, top clamping plate. top plate

动模座板 moving clamp plate. bottom clamping plate. bottom plate

上模座板 upper clamping plate

下模座板 lower clamping plate

凹模固定板 cavity-retainer plate

型芯固定板 core-retainer plate

凸模固定板 punch-retainer plate

模套 chase. bolster. frame

垫块 spacer parallel

支架 ejector housing. mould base leg 压力铸造模具 die-casting die

压铸模零部件

定模 fixed die, cover die

定模座板 fixed clamping plate

定模套板 bolstor, fixed die

动模 moving die,ejector die

动模座板 moving clamping plate

直流道 sprue

横流道 runner

内浇口 gate

模具专业英语词汇大全

模具专业英语词汇 A abrasion n. 磨损 abrasion resistance n. 耐磨损性 abrasive n. 磨料 accelerator n. 促进剂 accuracy n. 准确性 accurate die casting 精密压铸 air trap 积风 acrylic n. 丙烯酸 /压克力 ì active plate 活动板 additive n. 添加剂 adhere v. 黏附 adhesion n. 黏合 adhesive n. 胶粘剂 air-cushion eject-rod 气垫顶杆 air cushion plate 气垫板 air entrapment n. 困气 anneal v. 退火 assemble v. 总成 B back pressure 背压 bismuth mold 铋铸模 baffle plate 挡块 barrel n. 机筒 /料筒 / bending block 折刀 bottom block 下垫脚 bottom plate 下托板(底板) bushing bolck 衬套 barrel temperature 料筒温度 blush 发 blank through dies 漏件式落料模 burnishi blow molding n. 吹塑成型 blow molding machine n. 吹塑机 brittle adj. 脆性 bubble n. 气泡 burr 毛刺 button d by-product n. 副产品 C calendering n. 压延 carbon steel n. 碳素钢 casting n. 铸造 catalyst n. 催化剂 cavity n. 型腔 chemical resistance n. 耐化学腐蚀性 chip v. 削 /凿

开关按键的注塑模具设计说明书

开关按键的注塑模具设 计说明书 文档编制序号:[KKIDT-LLE0828-LLETD298-POI08]

目录 绪论 (3) 1.模塑工艺规程的编制 (5) 塑件的工艺性分析 (5) (5) (6) 计算塑件的体积和质量 (6) 塑件注塑工艺参数的确定 (7) 塑料成型设备的选取 (7) 2.注塑模的结构设计 (8) 分型面选择 (8) 确定型腔的数目及排列方式 (9) (9) (11) 浇注系统设计 (11) (11) (12) (13) (13) (14) 抽芯机构设计 (14) (14) (14) (15) (15) 滑块和导滑槽设计 (15) 导柱的设计 (15) 推出机构设计 (16) 成型零件结构设计 (16) (16) 3.外壳注塑模具的有关计算 (18)

4.模具加热和冷却系统的设计 (20) 5.模具闭合高度确定 (20) 计算模具的闭合高度 (21) 校核注塑机的开,合模空间 (21) (21) (21) 6.注塑机有关参数的校核 (21) 模具合模时校核 (21) 模具开模时校核 (22) 7.绘制模具总装图和非标零件工作图 (22) 本模具总装图和非标零件工作图见附图 (22) 本模具的工作原理 (22) 结论 (23) 致谢 (24) 参考文献 (25) 绪论 大学的学习即将结束,毕业设计是其中最后一个实践环节,是对以前所学的知识及所掌握的技能的综合运用和检验。随着我国经济的迅速发展,采用模具的生产技术得到愈来愈广泛的应用。 随着工业的发展,工业产品的品种和数量不断增加。换型不断加快。使模具的需要补断增加。而对模具的质量要求越来越高。模具技术在国民经济中的作用越来越显得更为重要。 根据业内专家预测,今年中国塑料模具市场总体规模将增加13%左右,到2005年塑料模具产值将达到460亿元,模具及模具标准件出口将从现在的9000多万美元增长到2005年的2亿美元左右,产值在增长,也就意味着市场在日渐扩大。 相当多的发达国家塑料模具企业移师中国,是国内塑料模具工业迅速发展的重要原因之一。中国技术人才水平的提高和平均劳动力成本低都是吸引外资的优势,所以中国塑模市场的前景一片辉煌,这是塑料模具市场迅速成长的重要因素所在。 按照我国国家标准,模具共分为10大类46个小类,塑料模具是10大类中的l 个大类,共有7个小类:热塑性塑料注塑模、热固性塑料注塑模、热固性塑料压塑

模具专业英文术语大全

模具英语专业术语 模具述语 一、入水:gate 进入位: gate location 水口形式:gate type 大水口:edge gate 细水口: pin-point gate 水口大小:gate size 转水口: switching runner/gate 唧嘴口径: sprue diameter 二、流道: runner 热流道: hot runner,hot manifold 热嘴冷流道: hot sprue/cold runner 唧嘴直流: direct sprue gate 圆形流道:round(full/half runner 流道电脑分析:mold flow analysis 流道平衡:runner balance 热嘴: hot sprue 热流道板:hot manifold 发热管:cartridge heater 探针: thermocouples 插头: connector plug 插座: connector socket 密封/封料: seal 三、运水:water line 喉塞:line lpug 喉管:tube 塑胶管:plastic tube 快速接头:jiffy quick connector plug/socker 四、模具零件: mold components 三板模:3-plate mold 二板模:2-plate mold 边钉/导边:leader pin/guide pin 边司/导套:bushing/guide bushing 中托司:shoulder guide bushing 中托边L:guide pin 顶针板:ejector retainner plate 托板: support plate 螺丝: screw 管钉:dowel pin 开模槽:ply bar scot 内模管位:core/cavity inter-lock 顶针: ejector pin 司筒:ejector sleeve 司筒针:ejector pin 推板:stripper plate 缩呵:movable core,return core core puller 扣机(尼龙拉勾):nylon latch lock 斜顶:lifter 模胚(架): mold base 上内模:cavity insert 下内模:core insert 行位(滑块): slide 镶件:insert 压座/斜鸡:wedge 耐磨板/油板:wedge wear plate 压条:plate 撑头: support pillar 唧嘴: sprue bushing 挡板:stop plate 定位圈:locating ring 锁扣:latch 扣鸡:parting lock set 推杆:push bar 栓打螺丝:S.H.S.B 顶板:eracuretun 活动臂:lever arm 分流锥:spure sperader 水口司:bush 垃圾钉:stop pin 隔片:buffle 弹弓柱:spring rod 弹弓:die spring 中托司:ejector guide bush 中托边:ejector guide pin 镶针:pin 销子:dowel pin 波子弹弓:ball catch 喉塞: pipe plug

外资企业模具英文常用对话

1. XXX!你现在有空吗,我可以问你一些问题吗? Could I ask you some questions if you are free?/ Are you free now? May I ask you some questions (a question)? 2.请问此产品的面是否为外观面?表面做什么处理?是晒纹/抛光? Can you tell me whether the surface of this part is a visible/esthetic one? What will we do for its surface? Texture or Polishing? 3.请问产品这个面可否加顶针或顶块?产品允许加扁顶针吗? Does this part need an ejector pin or an ejector bar? Can we add an ejector blade? 4.这个产品的柱位我们打算做司筒。(或镶针)可以吗? Can we add ejector sleeves or ejector pins in the boss of this part? 5.产品的这个位置不能出模,我们打算做行位,在此面上会有分模线,你接受吗? There's an undercut at this position and it needs a slider. It will also have a parting line on this side, is that OK? 6.产品里面的这个位置我们打算做斜顶或内行位,有问题吗? We will make the lifter and (inner) slider in this position, will that be a problem? 7.你提供的2D产品图与3D产品图不一致,请问以哪一个图面为准? The 2D and 3D drawing you provided is not the same, can you tell me which one is correct? 8.你提供的3D产品图有的地方没有出模角,有的地方胶位太厚,有的地方胶位太溥,这些产品问题我们可以自己修改吗?修改后会给交给你确认。 There is no draft angle in the 3D drawing, some materials are too thick, and some place are too thin. Can we modify this part by ourselves? We will send the drawing to you for you to check after we modify it.

塑胶模具专业英语

中文英文 机工,机器加工 machining,machine work O环,O形封垫 O ring 下料模,切料模 blanking die 寸进,寸动 inching 工程塑胶 engineering plastics 工模,夹具,支架 jig 干胶,粘著剂,动物胶 glue 干燥时间 drying time 干燥剂 drier dryer 不划一颜色,颜色深浅不均 color non-uni formity 中心浇口 center gate 内衬,衬套,衬蛰 liner 公差,容差 tolerance 分模线,合模线,模缝痕 parting line 切口,缺口 notch 切口,缺料 notch 切边(n) shear edge 化学腐蚀 chemical atching 化学腐蚀 chemical etching 反射 reflection 孔隙,空洞,气泡 void 尺寸稳定性 dimensional sability 手动压机 hand press 支管形喷嘴 nozzle manifold 比重 specific gravity 比热 specific heat 毛状裂痕 hair crack,hair cracking 毛绒 fuzz 毛边,凿纹 burr,flash,fin 水道,水通路 water channel 火花放电 spark discharge 火焰处理 flame treatment,flame treating 片材 sheet 凹痕,缩痕 sink mark,shrink mark 凹槽,内陷,凹陷 undercut 加料,给料,供料 feed 加热,加温 warming,warming up 加热板,热板(盘) heating plate 加热管套,加热缸 heating cylinder,heatin g barrel 加热炉 heating furnace 功率,力率 power factor 半透明 semitransparence,translucence 打眼,钻孔 driling 正余面,交叠,重叠 overlap 永久变形 permanent set,residual strain 白昙,雾状 haze 立式射出成型机 vertical injection mo(u)l ding machine 光彩,光泽 gloss 印刷 printing 同轴往复螺杆式射出成型机 in-line scre w(type)injecton mo(u)lding machine 合成树枝 synthetic resin 合板,集成材 composite wood 合模力,开模力 mo(u)ld clamping force, mo(u)ld locking force 合模线,毛边线 flash line,parting line 合模线,毛边线 spew line,spue line 合模销,导销 leader pin 合模销套,导销衬套 leader pin pushing 合模机构,开模机构 mo(u)ld clamping m echanism 后加工 post processing 后加热 after baking 后成型 postforming 回程销,复归销 return pin 安全系数 safety factor 安全门 safety door 成孔销,心型销,模蕊销 core pin 成孔销托板,动或定模板 core pin plate 成形 forming 成形,模制 mo(u)iding,forming

PR按键类模具设计教程

按键类模具设计

Ⅱ按键类模具设计总则 一、树立正确的观念 (一)什么是模具:模具就是用来生产某种指定产品的工具。即然模具只是生产产品的工具。所以制作模具并不是制模人员的目标。作业合格的产品才是我们一切努力的最终目标,而模具制作是这一过程中至关重要的环节。只有得到合格的产品,模具和模具设计才实现其价值。 (二)什么是按键模:按键模就是用来生产按键类产品的工具,按键类产品有如下共同的特点: 1 产品的尺寸相对较小,而尺寸精度要求高 2 产品一般有较高的表面要求 3 产品结构相对简单,但单件产品要求产量高 4 产品有诸如:电镀,印刷等后道工序 相对应于上述按键类产品的特点,按键类模具也有其相对应的特点: 1 模具精度要求高,一般重要尺寸控制为0.02MM 2 型腔、型芯的强度和表面质量要求高:一般型腔都要做到镜面抛光,故我们在选择工件 材料和加工工艺也要相应选用性能好的S136钢材,热处理后硬度为48-52HRC 3 在产品排布设计时,要设计边框和定位柱,以利于注塑工艺调整,以及产品后加工的固 定,产品运输过程中的包装和保护。 (三)按键类产品使用的材料: 1 ABS 用于空心电镀KEY或空心电镀 2 PC 用于空心透明KEY或实心透明KEY 3 PMMA 用于实心透明KEY 4 按键类产品成型后的处理程序以及模具设计时应注意的地方。 (1)表面电镀 1 整个表面都可以被电镀 (2)侧面和顶面可被电镀而底面不可以电镀 针对表面电镀的产品,模具设计时主要要考虑以下几点 1 产品的底面尽量设计成平面

2 LAYOUT 设计时,KEY间距有适当距离 3 流道上要设计挂点,方便电镀时固定产品, 挂点距离为40-50MM 4 在边框及流道上设计一小平面,方便电镀后检测电镀层的厚度 5 定位柱应朝向产品侧,以保护电镀KEY的表面 2 表面印刷: 1 定位柱的设计应朝向KEY的反面,以保证定位柱不刮破印刷丝网 2 流道边框等不能高于产品的KEY 顶面,以免干涉印刷 3 按键KEY与硅胶产品的装配 大多的按键KEY做好之后,都要装配到硅胶产品上, 装配一般是通过用胶水将按键KEY 粘在硅胶上来完成.所以,产品结构设计时必须设计合适的装配间隙和防呆结构. 二、模具设计: 在完成对产品的分析之后,我们要进入正式的模具设计。因按键类模具属于精度要求较高的模具,故模具设计应从以下几个方面着手分析: ㈠按键类模具的设计精度: 模具精度虽然与加工和年装配密切技术相关,但首先应具有较高的设计精度。如果在设计时没有提出恰当的技术要求,或模具结果本身设计不合理,则无论加工和装配技术有多高,模具的精度永远不可能得到保证,所以: 1.按键模各零部件的设计精度和技术要求要与产品精度相适应。按键模型腔、型芯以及分型面的精度相适应。一般模具的尺寸公差应小于产品公差的三分之一,按公司目前的要求,模具的设计和制造公差应控制在±0.02mm以内。 2.按键模的标准通用零部件,虽然不直接参与注射成型,但其精度却能够间接影响产品精度。为此,按键类模具的模架使用龙记标准模架,顶针及司筒使用进口顶针及司筒、浇口套、定位圈也可使用标准件。 3.按键模的结构必须要具有足够的刚度,防止它们在注射压力和合模力的作用下,发生大的弹性变形,影响产品的精度,故: ①模架及板模框适当加厚,并适当增加支撑柱,以防止模架变形 ②镶块选用优质的S136钢材,粗加工后进行热处理,其硬度达到48-52HRC ③设计合理的结构,比如锥面配合,设计凸块咬合结构类加强整体的刚度。 4.按键模应确保动、定模的对合精度。

模具专业英语——注塑模

Injection Mold Technical Terms 特克内克腾目思 (一)模具专业基本用词 Professional Terms Intensification Factor 增强比 Scientific molding 科学注塑英腾次分克深发克偷 塞音特菲克计数器counter康特 Specific Injection Pressure (Psi)特殊注塑压力 思呗色服克 1.塑料—plastic, resin瑞申油管:Oil pipe 尼龙--------nylon 2.样件—sample 调节板-------adjust plate 3.钢料—steel A板--------a plate 4.注塑机—injection machine, press 定位圈----locating ring 喽客厅令 5.产品—part, product, moulding 斜导柱-----angular pin 安给拉PIN 6.模具—mold, mould, tool B板--------- b plate A 简易模(样板模)—prototype mold B 量产用模具—production mold 7.三维造型(数模)—3D model, 滚珠导套-------ball ejector bush 8.二维产品图—2D part drawing 拽应扁顶针--------blade ejector pin 布累得 9.设计—design 低赛应下模板--------bottom clamping plate 抱腾 10.制造—manufacture, 上模型腔------cavity main insert 11.检验—check, 上模镶件------cavity sub insert 12.测量—measure, 妹试司筒针--------center pin 深特 13.修改—change, modify 下模型芯------core main insert 14.工程更改—engineer change 下模镶针------core pin 15.质量—quality 快乐体下模镶件------core sub insert 16.数量—quantity 宽体踢延迟顶针-------delay ejector pin 17.基准—datum, reference 拉杆限位钉--------distance bolt (二)如何解析2D 产品图?How to read 2D part drawing? 一.产品几何Geometry 顶距限位柱--------distance spacer 1.点—point 销钉-------dowel pin 2.线(边)—line, edge 顶块--------ejector bar 3.面face 顶板导套-----ejector leader pin A 侧面—side塞得 B表面—surface射飞思 C 外观面—appearance surface安皮尔思射飞思4.壁厚—wall thickness 我射克来思顶板导柱----ejector leader pin李德拼 5.加强筋(骨位)—rib 瑞布顶针-------ejector pin 6.孔—hole后顶针地板------ejector plate 7.细长的槽—slot 顶针面板-----ejector retain plate 瑞腾 8.柱位—boss 抱死顶棍------ejector rod

模具专业英文术语大全

实用文案 模具英语专业术语 模具述语开模槽:ply bar scot 内模管位:一、入水:gate core/cavity inter-lock 顶针:ejector pin 进入位:gate location 司筒:ejector sleeve 水口形式:gate type 司筒针:edge gate ejector pin 大水口:推板:细水口:stripper plate pin-point gate 缩呵:gate size movable core,return core core 水口大小:puller switching runner/gate 转水口:扣机(尼龙拉勾):nylon latch lock sprue diameter 唧嘴口径:斜顶:lifter : runner 二、流道模胚(架):mold base hot runner,hot manifold 热流道:上内模:cavity insert : hot sprue/cold runner 热嘴冷流道下内模:core insert : direct sprue gate 唧嘴直流行位(滑块):slide round(full/half runner 圆形流道:镶件:insert mold flow analysis 流道电脑分析:压座/斜鸡:wedge :runner balance 流道平衡耐磨板/油板:wedge wear plate hot sprue 热嘴:压条:plate hot manifold 热流道板:撑头: support pillar cartridge heater 发热管:唧嘴:sprue bushing : thermocouples 探针挡板:stop plate connector plug 插头:定位圈:locating ring connector socket 插座:锁扣:latch seal 封料:/密封扣鸡:parting lock set water line 三、运水:推杆:push bar line lpug 喉塞:栓打螺丝:S.H.S.B tube 喉管:顶板:eracuretun plastic tube 塑胶管:活动臂:lever arm jiffy quick connector 快速接头:分流锥:spure sperader plug/socker 水口司mold components 四、模具零件::bush 垃圾钉:三板模:3-plate mold stop pin 隔片:buffle 二板模:2-plate mold 弹弓柱:导边:/leader pin/guide pin spring rod 边钉弹弓:die spring 导套:边司/bushing/guide bushing 中托司:ejector guide bush 中托司:shoulder guide bushing 中托边:ejector guide pin guide pin :L中托边镶针:ejector retainner plate 顶针板:pin 销子:托板:support plate dowel pin 波子弹弓:ball catch screw 螺丝:: pipe plug dowel pin 管钉:喉塞文案大全. 实用文案 锁模块:lock plate Mold repair 模具维修 angle from pin 斜顶:Molds 模具

模具毕业设计99游戏机按钮注塑模具设计

目录 1引言------------------------------------------------------------------------------------------------------ 3 1.1塑料简介 -------------------------------------------------------------------------------------- 3 1.2注塑成型及注塑模-------------------------------------------------------------------------- 3 2 塑件材料分析------------------------------------------------------------------------------------------- 6 2.1 塑件材料的基本特性----------------------------------------------------------------------- 6 2.2 塑件材料成型性能-------------------------------------------------------------------------- 6 2.3 塑件材料成型条件-------------------------------------------------------------------------- 8 3 塑件的工艺分析 -------------------------------------------------------------------------------------- 9 3.1 塑件的结构设计----------------------------------------------------------------------------- 9 3.2 塑件尺寸及精度---------------------------------------------------------------------------- 11 3.3 塑件表面粗糙度---------------------------------------------------------------------------- 11 3.4 塑件的体积和质量------------------------------------------------------------------------- 12 4 注射成型工艺方案及模具结构的分析和确定------------------------------------------------ 12 4.1、注射成型工艺过程分析[5] ---------------------------------------------------------------- 12 4.2 浇口种类的确定 -------------------------------------------------------------------------- 13 4.3 型腔数目的确定---------------------------------------------------------------------------- 14 4.4 注射机的选择和校核 -------------------------------------------------------------------- 14 4.4.1 注射量的校核 ----------------------------------------------------------------------- 14 4.4.2 塑件在分型面上的投影面积与锁模力的校核------------------------------- 15 4.4.3、模具与注射机安装模具部分相关尺寸校核------------------------------- 15 5注射模具结构设计 ---------------------------------------------------------------------------------- 16 5.1 分型面的设计 ------------------------------------------------------------------------------- 16 5.2 型腔的布局 ---------------------------------------------------------------------------------- 17 5.3 浇注系统的设计---------------------------------------------------------------------------- 18 5.3.1 浇注系统组成 -------------------------------------------------------------------- 18 5.3.2 确定浇注系统的原则----------------------------------------------------------- 18 5.3.3 主流道的设计 -------------------------------------------------------------------- 19 5.3.4 分流道的设计 -------------------------------------------------------------------- 21 5.3.5 浇口的设计 ----------------------------------------------------------------------- 21 5.3.6 冷料穴的设计 -------------------------------------------------------------------- 22 5.4 注射模成型零部件的设计[7] ------------------------------------------------------------- 22 5.4.1 成型零部件结构设计----------------------------------------------------------- 23 5.4.2 成型零部件工作尺寸的计算 ------------------------------------------------- 23 5.5 排气结构设计 ------------------------------------------------------------------------------- 24 5.6 脱模机构的设计---------------------------------------------------------------------------- 25 5.6.1 脱模机构的选用原则----------------------------------------------------------- 25

模具英语专业术语

模具英语专业术语上内模:cavity insert 模具述语下内模:core insert 一、入水:gate行位(滑块):slide 进入位:gate location 镶件:insert 水口形式:gate type 压座/斜鸡:wedge 大水口:edge gate 耐磨板/油板:wedge wear plate 细水口:pin-point gate 压条:plate 水口大小:gate size 撑头: support pillar 转水口:switching runner/gate 唧嘴:sprue bushing 唧嘴口径:sprue diameter挡板:stop plate 二、流道: runner 定位圈:locating ring 热流道:hot runner,hot manifold锁扣:latch 热嘴冷流道: hot sprue/cold runner 扣鸡:parting lock set 唧嘴直流: direct sprue gate推杆:push bar 圆形流道:round(full/half runner 栓打螺丝:S.H.S.B 流道电脑分析:mold flow analysis顶板:eracuretun 流道平衡:runner balance 活动臂:lever arm 热嘴:hot sprue 分流锥:spure sperader 热流道板:hot manifold水口司:bush 发热管:cartridge heater 垃圾钉:stop pin 探针: thermocouples 隔片:buffle 插头:connector plug 弹弓柱:spring rod 插座:connector socket 弹弓:die spring 密封/封料:seal中托司:ejector guide bush 三、运水:water line中托边:ejector guide pin 喉塞:line lpug 镶针:pin 喉管:tube 销子:dowel pin 塑胶管:plastic tube 波子弹弓:ball catch 快速接头:jiffy quick connector plug/socker 喉塞: pipe plug 四、模具零件:mold components 锁模块:lock plate 三板模:3-plate mold斜顶:angle from pin 二板模:2-plate mold斜顶杆:angle ejector rod 边钉/导边:leader pin/guide pin 尼龙拉勾:parting locks 边司/导套:bushing/guide bushing 活动臂:lever arm 中托司:shoulder guide bushing 复位键、提前回杆:early return bar 中托边L:guide pin 气阀:valves 顶针板:ejector retainner plate 斜导边:angle pin 托板:support plate 术语:terms 螺丝:screw 承压平面平衡:parting surface support balance 管钉:dowel pin 模排气:parting line venting 开模槽:ply bar scot 回针碰料位:return pin and cavity interference 内模管位:core/cavity inter-lock模总高超出啤机规格:mold base shut hight 顶针:ejector pin 顶针碰运水:water line interferes withejector pin 司筒:ejector sleeve 料位出上/下模:part from cavith (core) side 司筒针:ejector pin 模胚原身出料位:cavity direct cut on A-plate,core direct cut 推板:stripper plate on B-plate. 缩呵:movable core,return core core puller 不准用镶件:Do not use (core/cavity) insert 扣机(尼龙拉勾):nylon latch lock用铍铜做镶件:use beryllium copper insert 斜顶:lifter 初步(正式)模图设计:preliinary (final) mold design 模胚(架):mold base 反呵:reverse core 弹弓压缩量:spring compressed length 稳定性好:good stability,stable 强度不够:insufficient rigidity 均匀冷却:even cooling 扣模:sticking 热膨胀:thero expansion 公差:tolorance 铜公(电极):copper electrode Mold & die components 模具单元 Mold changing systems 换模系统 Mold core 模芯 Mold heaters/chillers模具加热器 /冷却器 Mold polishing/texturing模具打磨/磨纹Mold repair模具维修

注塑模具英文论文

Low Cost Injection Mold Creation via Hybrid Additive and Conventional Manufacturing 1. Introduction In most industrial applications, the manufacturing cost of a plastic part is mainly governed by the amount of material used in the molding process. Thus, current approaches for plastic part design and manufacturing focus primarily on establishing the minimum part thickness to reduce material usage. The assumption is that designing the mold and molding processes to the minimum thickness requirement should lead to the minimum manufacturing cost. Nowadays, electronic products such as mobile phones and medical devices are becoming ever more complex and their sizes are continually being reduced. The demand for small and thin plastic components for miniaturization assembly has considerably increased in recent years. Other factors besides minimal material usage may also become important when manufacturing thin plastic components. In particular, for thin parts, the injection molding pressure may become significant and has to be considered in the first phase of manufacturing. Employing current design approaches for plastic parts will fail to produce the true minimum manufacturing cost in these cases. Thus, tackling thin plastic parts requires a new approach, alongside existing mold design principles and molding techniques. 1.1 Current research Today, computer-aided simulation software is essential for the design of plastic parts and molds. Such software increases the efficiency of the design process by reducing the design cost and lead time [1]. Major systems, such as Mold Flow and C-Flow, use finite element analysis to simulate the filling phenomena, including flow patterns and filling sequences. Thus, the molding conditions can be predicted and validated, so that early design modifications can be achieved. Although available software is capable of analyzing the flow conditions, and the stress and the temperature distribution conditions of the component under various molding scenarios, they do not yield design parameters with minimum manufacturing cost [2,3]. The output data of the software only give parameter value ranges for reference and leaves the decision making to the component designer. Several attempts have also been made to optimize the parameters in feeding [4–7], cooling [2,8,9], and ejection These attempts were based on maximizing the flow ability of molten material during the molding process by using empirical relation ships between the product and mold design parameters.