外文翻译-英文

BEHA VIOR OF INDIVIDUAL FASTENERS

Connections are generally classified according to the manner of stressing the fastener Section, that is, tension, shear or combined tension and shear. Typical examples of connections subjecting fasteners to shear are splices and gusset plates in trusses. Bolts in tension are common in hanger connections and in beam-to-column connections. Some beam-to-column connections may also subject the bolts to combined tension and shear. It is apparent that, before a connection can be analyzed, the behavior of the component parts of the connection must be known. Therefore, the behavior of a single bolt subjected to the typical loading conditions of tension, shear, or combined tension and shear is discussed in this section.

Bolts Subjected to Tension

Since the behavior of a bolt subjected to an axial load is governed by the perfor-mance of its threaded part, load versus elongation characteristics of a bolt are more significant than the stress versus strain relationship of the fastener metal itself.

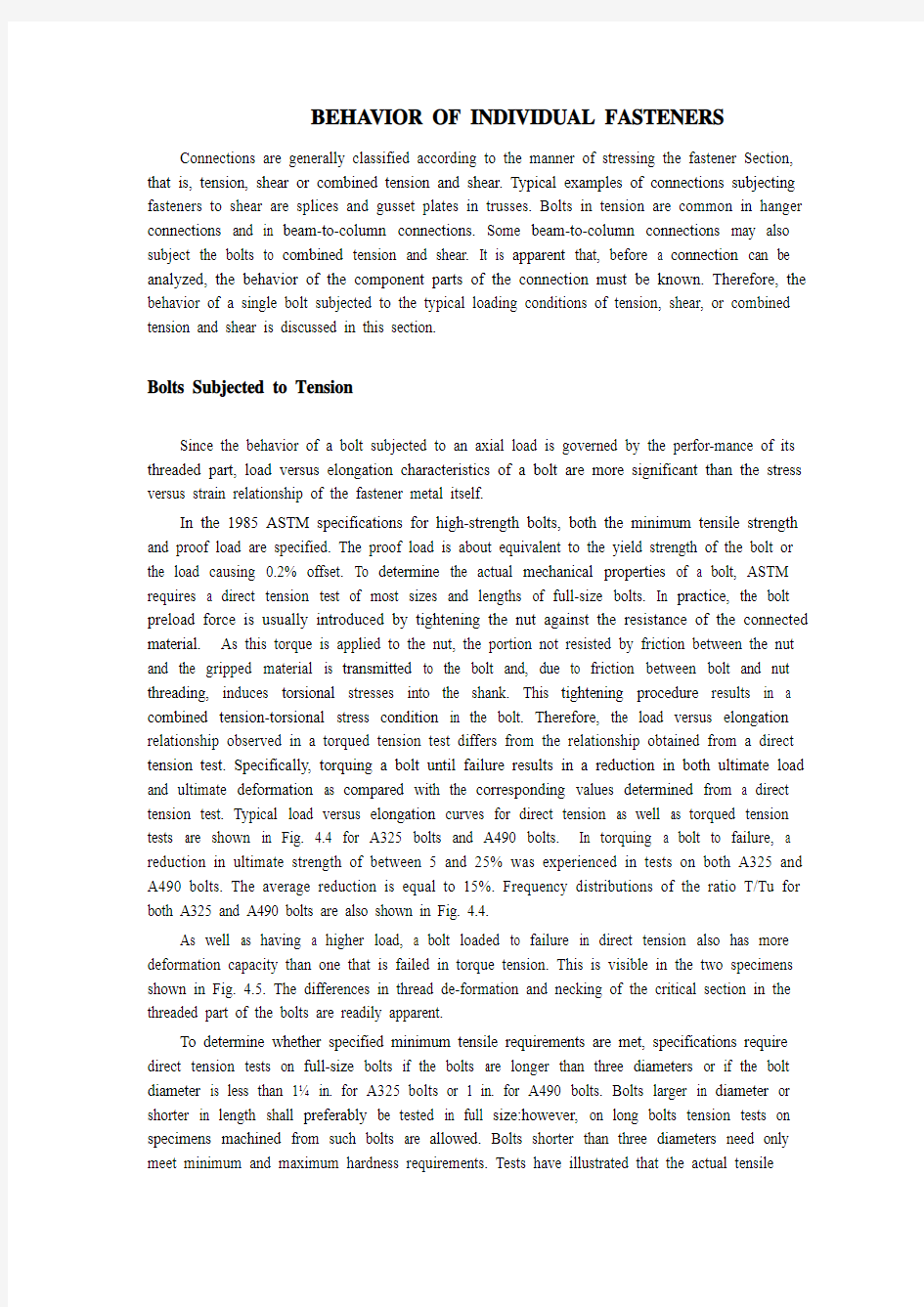

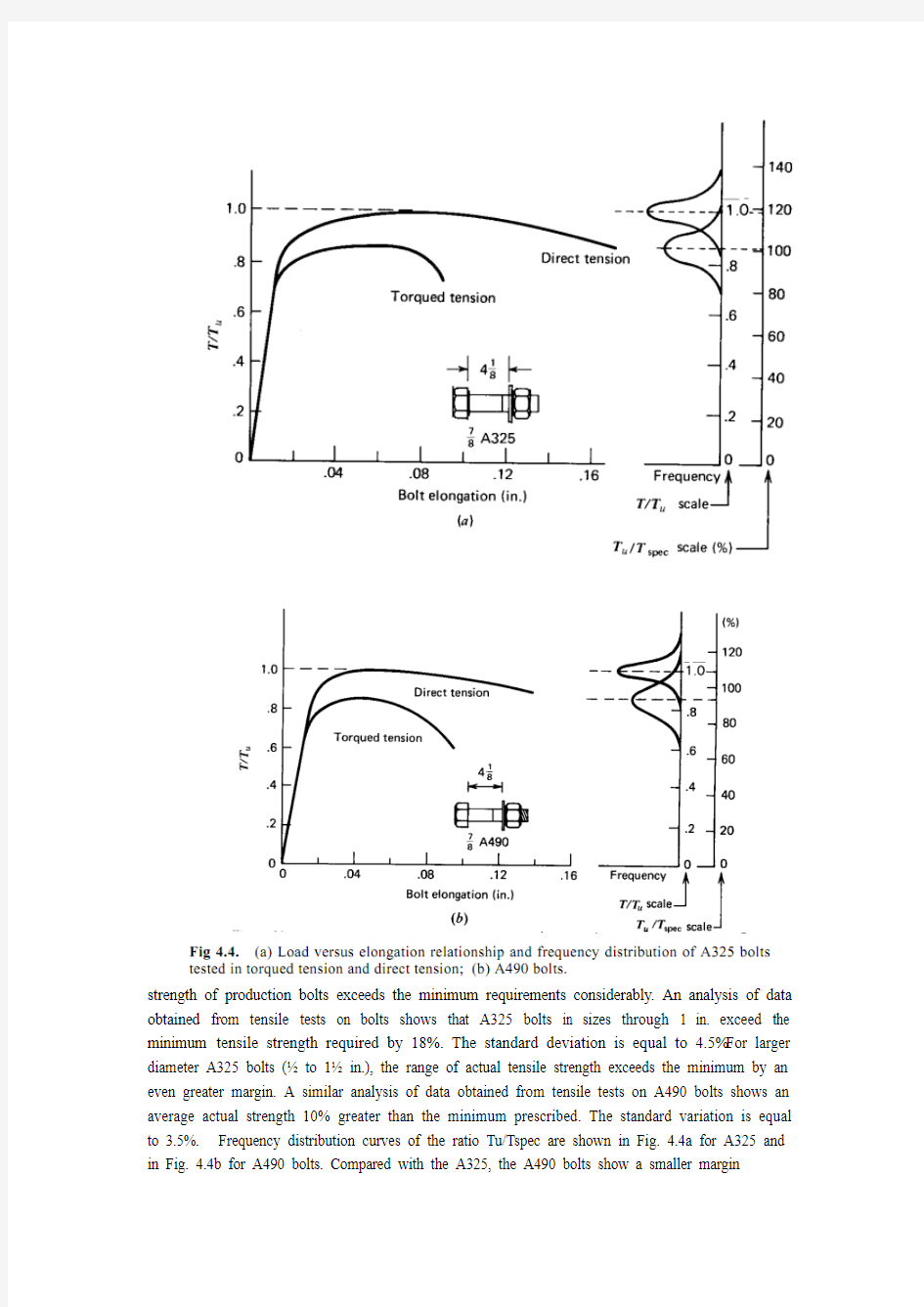

In the 1985 ASTM specifications for high-strength bolts, both the minimum tensile strength and proof load are specified. The proof load is about equivalent to the yield strength of the bolt or the load causing 0.2% offset. To determine the actual mechanical properties of a bolt, ASTM requires a direct tension test of most sizes and lengths of full-size bolts. In practice, the bolt preload force is usually introduced by tightening the nut against the resistance of the connected material. As this torque is applied to the nut, the portion not resisted by friction between the nut and the gripped material is transmitted to the bolt and, due to friction between bolt and nut threading, induces torsional stresses into the shank. This tightening procedure results in a combined tension-torsional stress condition in the bolt. Therefore, the load versus elongation relationship observed in a torqued tension test differs from the relationship obtained from a direct tension test. Specifically, torquing a bolt until failure results in a reduction in both ultimate load and ultimate deformation as compared with the corresponding values determined from a direct tension test. Typical load versus elongation curves for direct tension as well as torqued tension tests are shown in Fig. 4.4 for A325 bolts and A490 bolts. In torquing a bolt to failure, a reduction in ultimate strength of between 5 and 25% was experienced in tests on both A325 and A490 bolts. The average reduction is equal to 15%. Frequency distributions of the ratio T/Tu for both A325 and A490 bolts are also shown in Fig. 4.4.

As well as having a higher load, a bolt loaded to failure in direct tension also has more deformation capacity than one that is failed in torque tension. This is visible in the two specimens shown in Fig. 4.5. The differences in thread de-formation and necking of the critical section in the threaded part of the bolts are readily apparent.

To determine whether specified minimum tensile requirements are met, specifications require direct tension tests on full-size bolts if the bolts are longer than three diameters or if the bolt diameter is less than 1? in. for A325 bolts or 1 in. for A490 bolts. Bolts larger in diameter or shorter in length shall preferably be tested in full size:however, on long bolts tension tests on specimens machined from such bolts are allowed. Bolts shorter than three diameters need only meet minimum and maximum hardness requirements. Tests have illustrated that the actual tensile

strength of production bolts exceeds the minimum requirements considerably. An analysis of data obtained from tensile tests on bolts shows that A325 bolts in sizes through 1 in. exceed the minimum tensile strength required by 18%. The standard deviation is equal to 4.5%. For larger diameter A325 bolts (? to 1? in.), the range of actual tensile strength exceeds the minimum by an even greater margin. A similar analysis of data obtained from tensile tests on A490 bolts shows an average actual strength 10% greater than the minimum prescribed. The standard variation is equal to 3.5%. Frequency distribution curves of the ratio Tu/Tspec are shown in Fig. 4.4a for A325 and in Fig. 4.4b for A490 bolts. Compared with the A325, the A490 bolts show a smaller margin

beyond the specified tensile strength because specifications require the actual strength of A490 bolts to be within the range of 150 to 170 ksi, whereas for A325 only a minimum strength is specified.

Loading a bolt in direct tension after having preloaded it by tightening the nut (torqued tension) does not significantly decrease the ultimate tensile strength of the bolt, as illustrated in Figs. 4.6 and 4.7. The torsional stresses induced by torquing the bolt apparently have a negligible effect on the tensile strength of the bolt. This means that bolts installed by torquing can sustain direct tension loads without any apparent reduction in their ultimate tensile strength.

Mean load versus elongation curves for 15 regular head, 7/8-in. dia. A325 bolts of various grips are plotted in Fig. 4.8.The thickness of the gripped material varied from approximately 4? to 6? in., and the length of thread under the nut varied from ? to 1 in. No systematic variation existed among the load versus elongation relationships for the different grip conditions. Most of the deformation occurs in the threaded portion between the underside of the nut and the unthreaded part of the bolt. Because this length is relatively constant, the grip length has no appreciable effect on the load versus elongation response. The behavior shown in Fig. 4.8 for the direct tension test was also observed during torqued tension tests. With shorter grip lengths, the effect of bolt length is more pronounced.

Figure 4.8 also shows, within the elastic range, the elongation increases slightly with an increase in grip. As the load is increased beyond the elastic limit, the threaded part, which is approximately of uniform length, behaves plastically, while the shank remains essentially elastic. Hence, when there is a specific amount of thread under the nut, grip length has little effect on the load versus elongation relationship beyond the proportional limit. For short bolts, nearly all deformation occurs in the threaded length, with a resultant decrease in rotational capacity.

A325 bolts with heavy hex heads demonstrate behavior similar to that of bolts with regular heads for grips ranging from 4 to 8 in. and with thread lengths under the nut ranging from ? to ? in. Similar observations have also been made about A490 bolts. (Both A325 and A490 bolts are customarily furnished with heavy hexagonal heads unless other dimensional requirements have been agreed on.)

Since most of the elongation occurs in the threads, the length of thread between the thread run-out and the face of the nut will affect the load versus elongation relationship. The heavy head bolt has a short thread length, whereas the regular head bolt has the normal ASA thread length

specified by ANSI standards. As a result, for a given thickness of gripped material, the heavy head bolt shows a decrease in deformation capacity, as illustrated in Fig. 4.9.

Bolts Subjected to Shear

Shear load versus deformation relationships have been obtained by subjecting fasteners to

shear induced by plates either in tension or compression. Typical results of shear tests on A325 and A490 bolts are shown in Fig. 4.10. As expected, the increased tensile strength of A490 bolts as compared with A325 bolts results in an increased shear strength for that fastener. A slight decrease in deformation capacity is evident as the strength of the bolt increases.

The shear strength is influenced by the type of test. The fastener can be subjected to shear by plates in tension or compression, as illustrated in Fig. 4.11. The influence of the type of test on the bolt shear and deformation capacity is illustrated in Fig. 4.12, where typical shear stress versus deformation curves are compared for bolts from the same lot that were tested in both tension and compression jigs.

Test results show that the shear strength of bolts tested in A440 steel tension jigs is 6 to 13% lower than bolts tested in A440 steel compression jigs. The same trend was observed in constructional alloy steel jigs where the reduction in shear strength of similar bolts varied from 8 to 13%. The average shear strengths for A325 and A490* bolts tested in tension jigs were 80.1 and 101.1 ksi, respectively. These shear strengths correspond to about 62% of the respective actual tensile strengths of single bolts. The same bolt grades tested in compression jigs yielded shear strengths of 86.5 and 113.7 ksi, respectively (68% of the bolt tensile strength).

The lower shear strength of a bolt observed in a tension type shear test as compared with a compression type test (see Fig. 4.12) is the result of lap plate prying action, a phenomenon that tends to bend the lap plates of the tension jig outward. Because of the uneven bearing deformations of the test bolt, the resisting force does not act at the centerline of the lap plate. This produces a moment that tends to bend the lap plates away from the main plate and thereby causes tensile forces in the bolt.

Catenary action, resulting from bending in bolts, may also contribute to the increase in bolt tension near ultimate load. However, it is believed that this effect is small in comparison with the tension induced by lap plate prying action. In any case, the catenary action is present in both the tension and compression jigs. The tension jig is recommended as the preferred testing device because it produces a lower bound shear strength. Bolts in tension splices are subjected to shear in a similar manner. The tension jig shear test also yields the most consistent test results.

An examination of available test data indicates that the ratio of the shear strength to the tensile strength is independent of the bolt grade, as illustrated in Fig. 4.13. The shear strength is plotted versus the tensile strength for various lots of A325 and A490 bolts. The average shear

strength is approximately 62% of the tensile strength.

The variance of the ratio of the shear strength to tensile strength, as obtained from single bolt tension shear jigs, is shown in Fig. 4.14. A frequency curve of the ratio of shear strength to tensile strength was developed from test data acquired at the University of Illinois and Lehigh University. The average value is equal to 0.62, with a standard deviation of 0.03.

Tests on bolted joints indicated that the initial clamping force had no significant effect on the ultimate shear strength .A number of tests were performed on A325 and A490 bolts torqued to various degrees of tightness and then tested to failure in double shear. The results of tests with A490 bolts are shown in Fig. 4.15.The lower portion shows the relationship between bolt shear strength and the initial bolt elongation after installation. The bolt preload was determined from measured elongations and the torqued tension relationship given in the upper portion of Fig. 4.15. The results confirm that no significant variation of shear strength occurred when the initial bolt preload was varied. There are two sources of tensile load in the bolt that should, theoretically, interact with the shear load and result in a failure load that is less than that from shear alone. These are (1) the bolt preload induced during the installation procedure, and (2) bolt tension resulting from prying action in the plates.

Measurements of the internal tension in bolts in joints have shown that at ultimate load there is little preload left in the bolt. The shearing deformations that have taken place in the bolt prior to its failure have the effect of releasing the rather small amount of axial deformation that was used to induce the bolt preload during installation.

At any level of load producing shear in the bolts, prying action of the plates can also produce an axial tensile load in the bolts. In most practical situations, however, the tensile stress induced by prying action will be considerably below the yield stress of the bolt; therefore, it has only a minor influence. Studies of bolts under combined tension and shear have shown that tensile stresses equal to 20 to 30% of the tensile strength do not significantly affect the shear strength of the bolt.

The shear resistance of high-strength bolts is directly proportional to the available shear area. The available shear area in the threaded part of a bolt is equal to the root area and is less than the area of the bolt shank. For most commonly used bolts, the root area is about 70% of the nominal area. The influence of the shear plane location on the load versus deformation characteristics of

A325 and A490 bolts is reported in Ref. 4.4. Figure 4.16 shows the influence of the shear plane location on the load versus displacement behavior of A325 bolts. When both shear planes passed through the bolt shank, the shear load and deformation capacity were maximized. When both shear planes passed through the threaded portion, the lowest shear load and deformation capacity were obtained. All available tests indicate that the shear resistance of both A325 and A490 bolts is governed by the available shear area. The unit shear strength was unaffected by the shear plane location, however.

Bolts Subjected to Combined Tension and Shear

To provide information regarding the strength and behavior characteristics of single

high-strength bolts subjected to various combinations of tension and shear, tests were performed at the University of Illinois. Two types of high-strength bolts, A325 and A354 grade BD, were used in the investigation. Since the mechanical properties of A354 grade BD and A490 bolts are nearly identical, the data are also directly applicable to A490 bolts.

Certain other factors that might influence the performance of high-strength bolts under combined loadings of tension and shear were also examined in the test program. These included (1) bolt grip length, (2) bolt diameter, (3) type of bolt, and (4) type of material gripped by the bolt. In addition, the influence of the location of the shear planes was examined.

The Illinois tests indicated that an increase in bolt grip tends to increase the ultimate load of a bolt subjected to combined tension and shear. This increase in resistance is mainly caused by the greater bending that can develop in a long bolt as compared with a short grip bolt. At high loads the short grip bolt presented a circular shear area, whereas the long grip bolt, because of bending, presented an elliptical cross-section with a larger shear area.

It was concluded, however, that neither the test block material nor the bolt diameter had a significant effect on the ultimate load capacity of the bolt. Figure 4.17 summarizes test results of bolts subjected to combined tension and shear. The tensile strength (in kilopounds per square inch) was used to nondimensionalize the shear and tensile stresses due to the shear and tensile components of the load. The tensile stress was computed on the basis of the stress area, whereas the shear stress is dependent on the location of the shear plane. An elliptical interaction curve can be used to provide a good representation of the behavior of high-strength bolts under combined tension and shear; namely,

where x is the ratio of the shear stress on the shear plane to the tensile strength and y is the ratio of the tensile stress to the tensile strength (both computed on the stress area). Figure 4.17 also indicates that neither the bolt grade nor the location of the shear plane influence the ultimate x/y ratio. This is compatible with the behavior of bolts in pure shear.

英文文献翻译

中等分辨率制备分离的 快速色谱技术 W. Clark Still,* Michael K a h n , and Abhijit Mitra Departm(7nt o/ Chemistry, Columbia Uniuersity,1Veu York, Neu; York 10027 ReceiLied January 26, 1978 我们希望找到一种简单的吸附色谱技术用于有机化合物的常规净化。这种技术是适于传统的有机物大规模制备分离,该技术需使用长柱色谱法。尽管这种技术得到的效果非常好,但是其需要消耗大量的时间,并且由于频带拖尾经常出现低复原率。当分离的样本剂量大于1或者2g时,这些问题显得更加突出。近年来,几种制备系统已经进行了改进,能将分离时间减少到1-3h,并允许各成分的分辨率ΔR f≥(使用薄层色谱分析进行分析)。在这些方法中,在我们的实验室中,媒介压力色谱法1和短柱色谱法2是最成功的。最近,我们发现一种可以将分离速度大幅度提升的技术,可用于反应产物的常规提纯,我们将这种技术称为急骤色谱法。虽然这种技术的分辨率只是中等(ΔR f≥),而且构建这个系统花费非常低,并且能在10-15min内分离重量在的样本。4 急骤色谱法是以空气压力驱动的混合介质压力以及短柱色谱法为基础,专门针对快速分离,介质压力以及短柱色谱已经进行了优化。优化实验是在一组标准条件5下进行的,优化实验使用苯甲醇作为样本,放在一个20mm*5in.的硅胶柱60内,使用Tracor 970紫外检测器监测圆柱的输出。分辨率通过持续时间(r)和峰宽(w,w/2)的比率进行测定的(Figure 1),结果如图2-4所示,图2-4分别放映分辨率随着硅胶颗粒大小、洗脱液流速和样本大小的变化。

外文翻译 - 英文

The smart grid Smart grid is the grid intelligent (electric power), also known as the "grid" 2.0, it is based on the integration, high-speed bidirectional communication network, on the basis of through the use of advanced sensor and measuring technology, advanced equipme nt technology, the advanced control method, and the application of advanced technology of decision support system, realize the power grid reliability, security, economic, efficient, environmental friendly and use the security target, its main features include self-healing, incentives and include user, against attacks, provide meet user requirements of power quality in the 21st century, allow all sorts of different power generation in the form of access, start the electric power market and asset optimizatio n run efficiently. The U.S. department of energy (doe) "the Grid of 2030" : a fully automated power transmission network, able to monitor and control each user and power Grid nodes, guarantee from power plants to end users among all the nodes in the whole process of transmission and distribution of information and energy bi-directional flow. China iot alliance between colleges: smart grid is made up of many parts, can be divided into:intelligent substation, intelligent power distribution network, intelli gent watt-hourmeter,intelligent interactive terminals, intelligent scheduling, smart appliances, intelligent building electricity, smart city power grid, smart power generation system, the new type of energy storage system.Now a part of it to do a simple i ntroduction. European technology BBS: an integration of all users connected to the power grid all the behavior of the power transmission network, to provide sustained and effective economic and security of power. Chinese academy of sciences, institute of electrical: smart grid is including all kinds of power generation equipment, power transmission and distribution network, power equipment and storage equipment, on the basis of the physical power grid will be modern advanced sensor measurement technology, network technology, communication

机械设计设计外文文献翻译、中英文翻译、外文翻译

机械设计 摘要:机器是由机械装置和其它组件组成的。它是一种用来转换或传递能量的装置,例如:发动机、涡轮机、车辆、起重机、印刷机、洗衣机、照相机和摄影机等。许多原则和设计方法不但适用于机器的设计,也适用于非机器的设计。术语中的“机械装置设计”的含义要比“机械设计”的含义更为广泛一些,机械装置设计包括机械设计。在分析运动及设计结构时,要把产品外型以及以后的保养也要考虑在机械设计中。在机械工程领域中,以及其它工程领域中,所有这些都需要机械设备,比如:开关、凸轮、阀门、船舶以及搅拌机等。 关键词:设计流程设计规则机械设计 设计流程 设计开始之前就要想到机器的实际性,现存的机器需要在耐用性、效率、重量、速度,或者成本上得到改善。新的机器必需具有以前机器所能执行的功能。 在设计的初始阶段,应该允许设计人员充分发挥创造性,不要受到任何约束。即使产生了许多不切实际的想法,也会在设计的早期,即在绘制图纸之前被改正掉。只有这样,才不致于阻断创新的思路。通常,还要提出几套设计方案,然后加以比较。很有可能在这个计划最后决定中,使用了某些不在计划之内的一些设想。 一般的当外型特点和组件部分的尺寸特点分析得透彻时,就可以全面的设计和分析。接着还要客观的分析机器性能的优越性,以及它的安全、重量、耐用性,并且竞争力的成本也要考虑在分析结果之内。每一个至关重要的部分要优化它的比例和尺寸,同时也要保持与其它组成部分相协调。 也要选择原材料和处理原材料的方法。通过力学原理来分析和实现这些重要的特性,如那些静态反应的能量和摩擦力的最佳利用,像动力惯性、加速动力和能量;包括弹性材料的强度、应力和刚度等材料的物理特性,以及流体润滑和驱动器的流体力学。设计的过程是重复和合作的过程,无论是正式或非正式的进行,对设计者来说每个阶段都很重要。 最后,以图样为设计的标准,并建立将来的模型。如果它的测试是符合事先要

计算机网络-外文文献-外文翻译-英文文献-新技术的计算机网络

New technique of the computer network Abstract The 21 century is an ages of the information economy, being the computer network technique of representative techniques this ages, will be at very fast speed develop soon in continuously creatively, and will go deep into the people's work, life and study. Therefore, control this technique and then seem to be more to deliver the importance. Now I mainly introduce the new technique of a few networks in actuality live of application. keywords Internet Network System Digital Certificates Grid Storage 1. Foreword Internet turns 36, still a work in progress Thirty-six years after computer scientists at UCLA linked two bulky computers using a 15-foot gray cable, testing a new way for exchanging data over networks, what would ultimately become the Internet remains a work in progress. University researchers are experimenting with ways to increase its capacity and speed. Programmers are trying to imbue Web pages with intelligence. And work is underway to re-engineer the network to reduce Spam (junk mail) and security troubles. All the while threats loom: Critics warn that commercial, legal and political pressures could hinder the types of innovations that made the Internet what it is today. Stephen Crocker and Vinton Cerf were among the graduate students who joined UCLA professor Len Klein rock in an engineering lab on Sept. 2, 1969, as bits of meaningless test data flowed silently between the two computers. By January, three other "nodes" joined the fledgling network.

外文翻译computerprogram英文.doc

Computer Program 1 Introduction Computer Program, set of instructions that directs a computer to perform someprocessing function or combination of functions. For the instructions to be carried out, a computer must execute a program, that is, the computer reads the program, and then follow the steps encoded in the program in a precise order until completion. A program can be executed many different times, with each execution yielding a potentially different result depending upon the options and data that the user gives the computer. Programs fall into two major classes: application programs and operating systems. An application program is one that carries out somefunction directly for a user, such as word processing or game-playing. An operating system is a program that manages the computer and the various resources and devices connected to it, such as RAM,hard drives, monitors, keyboards, printers, and modems,so that they maybe used by other programs. Examples of operating systems are DOS, Windows 95, OS\2, and UNIX. 2 Program Development Software designers create new programs by using special applications programs, often called utility programs or development programs. A programmer uses another type of program called a text editor to write the new program in a special notation called a programming language. With the text editor, the programmer creates a text file, which is an ordered list of instructions, also called the program source file. The individual instructions that make up the program source file are called source code. At this point, a special applications program translates the source code into machine language, or object code— a format that the operating system

外文翻译中文

运作整合 供应链协作的首要问题是提高运作整合的程度。供应链协作课达到的好处,直接关系到捕捉效率之间的职能的企业,以及全国的企业,构成了国内或国际供应链。本章重点阐述的挑战,一体化管理,由研究为什么一体化创造价值,并通过详列的挑战,双方的企业集成和供应链整合。必不可少的供应链流程是确定的。注意的是,然后向信息技术提供,以方便集成化供应链规划。本章最后审查了定价。在最后的分析,定价的做法和政府是至关重要的供应链的连续性。 为什么整合创造价值 基本的优点与挑战的综合管理介绍了在第1章。进一步解释整合管理的重要性,有用的指出客户都至少有三个角度的价值。 传统的角度来看,价值是经济价值。第二个价值的角度来看,是市场价值。 实现双方经济和市场价值是很重要的客户。然而,越来越多的企业认识到商业上的成功也取决于第三个角度来看,价值,被称为关联性。 物流一体化目标 为实现物流一体化的供应链背景下,6个业务目标必须同时取得:( 1 )响应,( 2 )差额减少,( 3 )库存减少,( 4 )托运巩固,( 5 )质量,( 6 )生命周期支持。的相对重要性,每个直接关系到公司的物流战略。 响应 一公司的工作能力,以满足客户的要求,及时被称为反应。作为一再指出,信息技术是促进反应为基础的战略,允许业务的承诺被推迟到最后可能时间,其次是加速投放。实施对应策略服务,以减少库存承诺或部署在预期客户的需求。响应服务转向业务重点从预测未来的需求,以容纳顾客对快速订单到出货的基础上。理想的情况是,在一个负责任的系统中,库存是没有部署,直到客户承诺。支持这样的承诺,公司必须有物流的属性,库存的可用性和及时交付,一旦客户订单收到。 差异减少 所有经营领域的物流系统很容易受到差额。方差结果从未能履行任何预期的层面后勤业务不如预期。举例来说,毫不拖延地在客户订单处理,意想不到的干扰,以便选择,抵港货物损坏,在客户的位置,和/或未能提供在适当的位置上的时间,所有创造无计划的差异,在订单到交货周期。一个共同的解决办法,以保障对不利的差异是使用库存安全库存,以缓冲行动。这亦是共同使用的首选运输,以克服意想不到的差异延误交货计划。这种做法,鉴于其相关的成本高,可以尽量减少使用资讯科技,以维持积极的物流控制。向程度的差异是最小化,物流的生产力将提高。因此,差异减少,消除系统中断,是一个基本的目标,综合物流管理。 库存减少 要达到的目标,库存减少,一个综合物流系统必须控制资产的承诺,并把速度。资产的承诺,是财政的价值部署清单。把速度,反映了利率,这是充实库存随着时间的推移。高转率,再加上预期的库存供货,平均资产用于库存正在迅速而有效利用,这就是整体资产承诺支持一个综合运作减至最低。 库存能够而且确实方便可取的好处这是很重要的要请记住。库存是至关重要的实现规模经济,在制造业和采购。目的是要减少和管理存货,以尽可能最低的水平,同时实现整体供应链绩效的目标。

机械设计外文翻译(中英文)

机械设计理论 机械设计是一门通过设计新产品或者改进老产品来满足人类需求的应用技术科学。它涉及工程技术的各个领域,主要研究产品的尺寸、形状和详细结构的基本构思,还要研究产品在制造、销售和使用等方面的问题。 进行各种机械设计工作的人员通常被称为设计人员或者机械设计工程师。机械设计是一项创造性的工作。设计工程师不仅在工作上要有创造性,还必须在机械制图、运动学、工程材料、材料力学和机械制造工艺学等方面具有深厚的基础知识。如前所诉,机械设计的目的是生产能够满足人类需求的产品。发明、发现和科技知识本身并不一定能给人类带来好处,只有当它们被应用在产品上才能产生效益。因而,应该认识到在一个特定的产品进行设计之前,必须先确定人们是否需要这种产品。 应当把机械设计看成是机械设计人员运用创造性的才能进行产品设计、系统分析和制定产品的制造工艺学的一个良机。掌握工程基础知识要比熟记一些数据和公式更为重要。仅仅使用数据和公式是不足以在一个好的设计中做出所需的全部决定的。另一方面,应该认真精确的进行所有运算。例如,即使将一个小数点的位置放错,也会使正确的设计变成错误的。 一个好的设计人员应该勇于提出新的想法,而且愿意承担一定的风险,当新的方法不适用时,就使用原来的方法。因此,设计人员必须要有耐心,因为所花费的时间和努力并不能保证带来成功。一个全新的设计,要求屏弃许多陈旧的,为人们所熟知的方法。由于许多人墨守成规,这样做并不是一件容易的事。一位机械设计师应该不断地探索改进现有的产品的方法,在此过程中应该认真选择原有的、经过验证的设计原理,将其与未经过验证的新观念结合起来。 新设计本身会有许多缺陷和未能预料的问题发生,只有当这些缺陷和问题被解决之后,才能体现出新产品的优越性。因此,一个性能优越的产品诞生的同时,也伴随着较高的风险。应该强调的是,如果设计本身不要求采用全新的方法,就没有必要仅仅为了变革的目的而采用新方法。 在设计的初始阶段,应该允许设计人员充分发挥创造性,不受各种约束。即使产生了许多不切实际的想法,也会在设计的早期,即绘制图纸之前被改正掉。只有这样,才不致于堵塞创新的思路。通常,要提出几套设计方案,然后加以比较。很有可能在最后选定的方案中,采用了某些未被接受的方案中的一些想法。

变电站_外文翻译_外文文献_英文文献_变电站的综合概述

英文翻译 A comprehensive overview of substations Along with the economic development and the modern industry developments of quick rising, the design of the power supply system become more and more completely and system. Because the quickly increase electricity of factories, it also increases seriously to the dependable index of the economic condition, power supply in quantity. Therefore they need the higher and more perfect request to the power supply. Whether Design reasonable, not only affect directly the base investment and circulate the expenses with have the metal depletion in colour metal, but also will reflect the dependable in power supply and the safe in many facts. In a word, it is close with the economic performance and the safety of the people. The substation is an importance part of the electric power system, it is consisted of the electric appliances equipments and the Transmission and the Distribution. It obtains the electric power from the electric power system, through its function of transformation and assign, transport and safety. Then transport the power to every place with safe, dependable, and economical. As an important part of power’s transport and control, the transformer substation must change the mode of the traditional design and control, then can adapt to the modern electric power system, the development of modern industry and the of trend of the society life. Electric power industry is one of the foundations of national industry and national economic development to industry, it is a coal, oil, natural gas, hydropower, nuclear power, wind power and other energy conversion into electrical energy of the secondary energy industry, it for the other departments of the national economy fast and stable development of the provision of adequate power, and its level of development is a reflection of the country's economic development an important indicator of the level. As the power in the industry and the importance of the national economy, electricity transmission and distribution of electric energy used in these areas is an indispensable component.。Therefore, power transmission and distribution is critical. Substation is to enable superior power plant power plants or power after adjustments to the lower load of books is an important part of power transmission. Operation of its functions, the capacity of a direct impact on the size of the lower load power, thereby affecting the industrial production and power consumption.Substation system if a link failure, the system will protect the part of action. May result in power outages and so on, to the production and living a great disadvantage. Therefore, the substation in the electric power system for the protection of electricity reliability,

机械专业外文翻译(中英文翻译)

外文翻译 英文原文 Belt Conveying Systems Development of driving system Among the methods of material conveying employed,belt conveyors play a very important part in the reliable carrying of material over long distances at competitive cost.Conveyor systems have become larger and more complex and drive systems have also been going through a process of evolution and will continue to do so.Nowadays,bigger belts require more power and have brought the need for larger individual drives as well as multiple drives such as 3 drives of 750 kW for one belt(this is the case for the conveyor drives in Chengzhuang Mine).The ability to control drive acceleration torque is critical to belt conveyors’performance.An efficient drive system should be able to provide smooth,soft starts while maintaining belt tensions within the specified safe limits.For load sharing on multiple drives.torque and speed control are also important considerations in the drive system’s design. Due to the advances in conveyor drive control technology,at present many more reliable.Cost-effective and performance-driven conveyor drive systems covering a wide range of power are available for customers’ choices[1]. 1 Analysis on conveyor drive technologies 1.1 Direct drives Full-voltage starters.With a full-voltage starter design,the conveyor head shaft is direct-coupled to the motor through the gear drive.Direct full-voltage starters are adequate for relatively low-power, simple-profile conveyors.With direct fu11-voltage starters.no control is provided for various conveyor loads and.depending on the ratio between fu11-and no-1oad power requirements,empty starting times can be three or four times faster than full load.The maintenance-free starting system is simple,low-cost and very reliable.However, they cannot control starting torque and maximum stall torque;therefore.they are

博物馆 外文翻译 外文文献 英文文献

第一篇: 航空博物馆与航空展示公园 巴特罗米耶杰·基谢列夫斯基 飞翔的概念、场所的精神、老机场的建筑---克拉科夫新航空博物馆理性地吸取了这些元素,并将它们整合到一座建筑当中。Rakowice-Czyzyny机场之前的旧飞机修理库为新建筑的平面和高度设定了模数比例。在此基本形态上进一步发展,如同裁切和折叠一架纸飞机,生成了一座巨大的建筑。其三角形机翼是由混凝土制成,却如同风动螺旋桨一样轻盈。这个机翼宽大通透,向各个方向开敞。它们的形态与组织都是依据内部功能来设计的。机翼部分为3个不平衡的平面,使内外景观在不断变化中形成空间的延续性,并且联系了建筑内的视觉焦点和室外的展览区。 新航空展示公园的设计连接了博物馆的8栋建筑和户外展览区,并与历史体验建立联系。从前的视觉轴线与通道得到尊重,旧的道路得到了完善,朝向飞机场和跑道的空间被限定出来。每栋建筑展示了一个主题或是一段飞行史。建筑周围伸展出巨大的平台,为特殊主题的室外展览提供了空间。博物馆容纳了超过150架飞机、引擎、飞行复制品、成套的技术档案和历史图片。这里的特色收藏是飞机起源开始的各种飞行器,如Jatho1903、Grade1909、莱特兄弟1909年的飞机模型和1911年的鸽式单翼机。 The first passage: Museum for aviation and aviation exhibition park Bartiomiej Kislelewski The idea of flying, the spirit of place, the structure of the historic airfield – the new Museum of Aviation in Krakow takes up these references intellectually and synthesizes them into a building. The old hangars of the former airport Rakowice Czyzyny set the modular scale for the footprint and the height of the new building. Developed from this basic shape, as if cut out and folded like a paper airplane, a large structure has been generated, with triangular wings made of concrete and yet as light as a wind-vane propeller. The wings are generously glazed and open in all directions. Their form and arrangement depend on the interior uses. In the floor plans of the wings, the three offset

机械设计外文翻译(中英文)

盛年不重来,一日难再晨。及时宜自勉,岁月不待人。 机械设计理论 机械设计是一门通过设计新产品或者改进老产品来满足人类需求的应用技术科学。它涉及工程技术的各个领域,主要研究产品的尺寸、形状和详细结构的基本构思,还要研究产品在制造、销售和使用等方面的问题。 进行各种机械设计工作的人员通常被称为设计人员或者机械设计工程师。机械设计是一项创造性的工作。设计工程师不仅在工作上要有创造性,还必须在机械制图、运动学、工程材料、材料力学和机械制造工艺学等方面具有深厚的基础知识。如前所诉,机械设计的目的是生产能够满足人类需求的产品。发明、发现和科技知识本身并不一定能给人类带来好处,只有当它们被应用在产品上才能产生效益。因而,应该认识到在一个特定的产品进行设计之前,必须先确定人们是否需要这种产品。 应当把机械设计看成是机械设计人员运用创造性的才能进行产品设计、系统分析和制定产品的制造工艺学的一个良机。掌握工程基础知识要比熟记一些数据和公式更为重要。仅仅使用数据和公式是不足以在一个好的设计中做出所需的全部决定的。另一方面,应该认真精确的进行所有运算。例如,即使将一个小数点的位置放错,也会使正确的设计变成错误的。 一个好的设计人员应该勇于提出新的想法,而且愿意承担一定的风险,当新的方法不适用时,就使用原来的方法。因此,设计人员必须要有耐心,因为所花费的时间和努力并不能保证带来成功。一个全新的设计,要求屏弃许多陈旧的,为人们所熟知的方法。由于许多人墨守成规,这样做并不是一件容易的事。一位机械设计师应该不断地探索改进现有的产品的方法,在此过程中应该认真选择原有的、经过验证的设计原理,将其与未经过验证的新观念结合起来。 新设计本身会有许多缺陷和未能预料的问题发生,只有当这些缺陷和问题被解决之后,才能体现出新产品的优越性。因此,一个性能优越的产品诞生的同时,也伴随着较高的风险。应该强调的是,如果设计本身不要求采用全新的方法,就没有必要仅仅为了变革的目的而采用新方法。 在设计的初始阶段,应该允许设计人员充分发挥创造性,不受各种约束。即使产生了许多不切实际的想法,也会在设计的早期,即绘制图纸之前被改正掉。只有这样,才不致于堵塞创新的思路。通常,要提出几套设计方案,然后加以比较。很有可能在最后选定的方案中,采用了某些未被接受的方案中的一些想法。

外文翻译中文版(完整版)

毕业论文外文文献翻译 毕业设计(论文)题目关于企业内部环境绩效审计的研究翻译题目最高审计机关的环境审计活动 学院会计学院 专业会计学 姓名张军芳 班级09020615 学号09027927 指导教师何瑞雄

最高审计机关的环境审计活动 1最高审计机关越来越多的活跃在环境审计领域。特别是1993-1996年期间,工作组已检测到环境审计活动坚定的数量增长。首先,越来越多的最高审计机关已经活跃在这个领域。其次是积极的最高审计机关,甚至变得更加活跃:他们分配较大部分的审计资源给这类工作,同时出版更多环保审计报告。表1显示了平均数字。然而,这里是机构间差异较大。例如,环境报告的数量变化,每个审计机关从1到36份报告不等。 1996-1999年期间,结果是不那么容易诠释。第一,活跃在环境审计领域的最高审计机关数量并没有太大变化。“活性基团”的组成没有保持相同的:一些最高审计机关进入,而其他最高审计机关离开了团队。环境审计花费的时间量略有增加。二,但是,审计报告数量略有下降,1996年和1999年之间。这些数字可能反映了从量到质的转变。这个信号解释了在过去三年从规律性审计到绩效审计的转变(1994-1996年,20%的规律性审计和44%绩效审计;1997-1999:16%规律性审计和绩效审计54%)。在一般情况下,绩效审计需要更多的资源。我们必须认识到审计的范围可能急剧变化。在将来,再将来开发一些其他方式去测算人们工作量而不是计算通过花费的时间和发表的报告会是很有趣的。 在2000年,有62个响应了最高审计机关并向工作组提供了更详细的关于他们自1997年以来公布的工作信息。在1997-1999年,这62个最高审计机关公布的560个环境审计报告。当然,这些报告反映了一个庞大的身躯,可用于其他机构的经验。环境审计报告的参考书目可在网站上的最高审计机关国际组织的工作组看到。这里这个信息是用来给最高审计机关的审计工作的内容更多一些洞察。 自1997年以来,少数环境审计是规律性审计(560篇报告中有87篇,占16%)。大多数审计绩效审计(560篇报告中有304篇,占54%),或组合的规律性和绩效审计(560篇报告中有169篇,占30%)。如前文所述,绩效审计是一个广泛的概念。在实践中,绩效审计往往集中于环保计划的实施(560篇报告中有264篇,占47%),符合国家环保法律,法规的,由政府部门,部委和/或其他机构的任务给访问(560篇报告中有212篇,占38%)。此外,审计经常被列入政府的环境管理系统(560篇报告中有156篇,占28%)。下面的元素得到了关注审计报告:影响或影响现有的国家环境计划非环保项目对环境的影响;环境政策;由政府遵守国际义务和承诺的10%至20%。许多绩效审计包括以上提到的要素之一。 1本文译自:S. Van Leeuwen.(2004).’’Developments in Environmental Auditing by Supreme Audit Institutions’’ Environmental Management Vol. 33, No. 2, pp. 163–1721

机器人外文翻译(文献翻译-中英文翻译)

外文翻译 外文资料: Robots First, I explain the background robots, robot technology development. It should be said it is a common scientific and technological development of a comprehensive results, for the socio-economic development of a significant impact on a science and technology. It attributed the development of all countries in the Second World War to strengthen the economic input on strengthening the country's economic development. But they also demand the development of the productive forces the inevitable result of human development itself is the inevitable result then with the development of humanity, people constantly discuss the natural process, in understanding and reconstructing the natural process, people need to be able to liberate a slave. So this is the slave people to be able to replace the complex and engaged in heavy manual labor, People do not realize right up to the world's understanding and transformation of this technology as well as people in the development process of an objective need. Robots are three stages of development, in other words, we are accustomed to regarding robots are divided into three categories. is a first-generation robots, also known as teach-type robot, it is through a computer, to control over one of a mechanical degrees of freedom Through teaching and information stored procedures, working hours to read out information, and then issued a directive so the robot can repeat according to the people at that time said the results show this kind of movement again, For example, the car spot welding robots, only to put this spot welding process, after teaching, and it is always a repeat of a work It has the external environment is no perception that the force manipulation of the size of the work piece there does not exist, welding 0S It does not know, then this fact from the first generation robot, it will exist this shortcoming, it in the 20th century, the late 1970s, people started to study the second-generation robot, called Robot with the feeling that This feeling with the robot is similar in function of a certain feeling, for