挪威法 NTM Norwegian Method of Tunneling

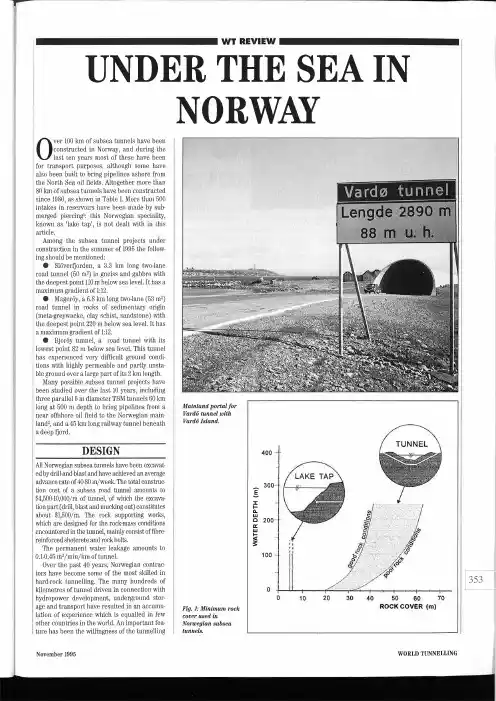

挪威海底隧道

TTPE

w

B

YEAR

1980

1982 1983

LDNGTÍI

DDEPEST

POIIVT

-93

cR0ss

SECTION

10mz

ßocK

clays,limestone

slate, sandstone

l.0lcn

km 0.4lan

2.6

m

the maximum gradient of the tunnel. The minimum safe distance between the tunnel roof and the rock surface under the sea (the rock cover) is a crucial dimension in locating a subsea tunnel, The minimum rock cover must be sufficiently thick to allow unexpected rock falls or cave-ins to occur without causing a criticaÌ situation in the tunnels. For road tunnels a minimum cover of 50 m is used during planning, until the results of detailed investigations are available. The rock cover requirements may be reduced to 40 m if the ground conditions are thoroughly documented to have a satisfactory qualitya (Fig.1). In addition to documentation of ground conditions, cross sections and gradienis which are common for all tunnels, subsea tunnels require special design criteria, These are mainly related to the conditions mentioned in Table IL A special feature for subsea tunnels is the rela-

土木外文文献与翻译--新奥法(NATM)隧道设计

NATM tunnel design principle in the construction of major andConstruction TechnologyW.BroereI.The NATM Design Principle1.Tunnel design and construction of two major theoretical and development processSince the 20th century, human space on the ground floor of the growing demand, thus the underground works of the study of a rapid development. In a large number of underground engineering practice, it is generally recognized that the tunnel and underground cavern project, the core of the problem, all up in the excavation and retaining two key processes. How excavation, it will be more conducive to the stability and cavern facilitate support : For more support, Supporting how they can more effectively ensure stability and facilitate the cavern excavation. This is the tunnels and underground works two promote each other and check each other's problems.Tunnels and underground caverns, and focusing on the core issues with the above practice and research, in different periods, People of different theories and gradually established a system of different theories, Each system includes theory and resolve (or are studying the resolution) from the works of understanding (concept), mechanics, engineering measures to the construction methods (Technology), a series of engineering problems.A theory of the 20th century the 1920s the traditional "load relaxation theory." Its core content is : a stable rock self-stability, no load : unstable rock may have collapsed. need shoring structure to be supported. Thus, the role of the supporting structure of the rock load is within a certain range may be due to relaxation and collapse of rock gravity. This is a traditional theory, and their representative is Taishaji and Principe's and others. It works similar to the surface issues of the thinking is still widely used to.Another theory of the 20th century made the 1950s the modern theory of timbering or "rock for the theory." Its core content is : rock stability is clearly bearing rock to their own self-stability : unstable rock loss of stability is a process, and if this process in providing thenecessary help or restrictions will still be able to enter the rock steady state. This theoretical system of representative characters Labuxiweici, Miller-Feiqieer, Fenner - Daluobo and Kashitenai others. This is a more modern theory, it is already out of the ground works to consider the ideas, and underground works closer to reality, the past 50 years has been widely accepted and applied. demonstrated broad development prospects.Can be seen from the above, the former theory more attention to the findings and the results of treatment : The latter theory is even more attention to the process and the control of the process, right from the rock for the full utilization of capacity. Given this distinction, which both theory and methods in the process, each with different performance characteristics. NATM theory is rock for the tunnel engineering practice in the representation method.2. NATMNATM that the new Austrian Tunneling Method short the original is in New Austrian Tunneling Method, referred to as the NATM. France said it convergence bound or some countries alleged to observe the dynamic design and construction of the basic principles.NATM concept of filibustering Xiweici Austria scholars in the 20th century, Professor age of 50. It was based on the experience of both the tunnel and rock mechanics theory, will bolt and shotcrete combination as a major means of supporting a construction method, Austria, Sweden, Italy and other countries, many practical and theoretical study in the 1960s and patented officially named. Following this approach in Western Europe, Scandinavia, the United States and Japan and many other underground works with a very rapid development, have become modern tunnels new technologies landmark. Nearly 40 years ago, the railway sector through research, design, construction combining, in many construction of the tunnel, according to their own characteristics successfully applied a new Austrian law, made more experience, have accumulated large amounts of data, This is the application stage. However, in the road sector NATM of only 50%. Currently, the New Austrian Tunneling Method almost become weak and broken rock section of a tunnel construction method, technical and economic benefits are clear. NATM the basic points can be summarized as follows : (1). Rock tunnel structure is the main loading unit, the construction must fully protect the rock, it minimize the disturbance to avoid excessive damage to the intensity of rock. Tothis end, the construction of sub-section should not block too much, excavation should be used smooth blasting, presplit blasting or mechanical tunneling.(2). In order to give full play to rock the carrying capacity should be allowed to control and rock deformation. While allowing deformation, which can be a rock bearing ring; The other hand, have to limit it, Rock is not so lax and excessive loss or greatly reduced carrying capacity. During construction should be used with rock close to, the timely building puzzle keeps strengthening Flexible support structure, such as bolting and shotcreting supporting. This adjustment will be adopted supporting structural strength, Stiffness and its participation in the work of the time (including the closure of time) to control the deformation of the rock mass.(3). In order to improve the support structure, the mechanical properties, the construction should be closed as soon as possible, and to become a closed cylindrical structure. In addition, the tunnel shape with a round should, as far as possible, to avoid the corner of the stress concentration.(4). Construction right through the rock and supporting the dynamic observation, measurement, and reasonable arrangements for the construction procedures, changes in the design and construction management of the day-to-day.(5). To lay waterproof layer, or is subject to bolt corrosion, deterioration of rock properties, rheological, swelling caused by the follow-up to load, use composite lining.(6). Lining in principle, and the early rock deformation Supporting the basic stability of the conditions under construction. rock and supporting structure into a whole, thereby improving the support system of security.NATM above the basic elements can be briefly summarized as : "less disturbance, early spray anchor, ground measurements, closed tight."3.With a spring to understand the principle NATM(1). Cavern brink of a point A in the original excavation ago with stress (stress self-respect and tectonic stress) in a state of equilibrium. As an elastic stiffness of the spring K, P0 under compression in a state of equilibrium.(2). Cavern excavation, A point in attacking lose face constraints, the original stress state to be adjusted, if the intensity of rock big enough, After less stress adjustments maycavern in a stable condition (without support). But most of the geological conditions of the poor, that is, after the stress cavern adjustments, such as weak protection, we could have convergence deformation, even instability (landslides), must be provided to support power PE, in order to prevent landslides instability. Equivalent to the Spring of deformation u, in the role of PE is now in the midst of a state of equilibrium.(3). By the mechanical balance equation, we can see in the spring P0 role in a state of equilibrium; Spring in the event of deformation u, PE in the role they will be in equilibrium, assuming spring elasticity of K, were : P0=PE+KuDiscussion :(1) When u = 0, that is not allowed P0=PE rock deformation, is a rigid support, not economic;(2) when u ↑, PE ↓; When u ↓, PE ↑. That is, rock deformation occurred, the release of some of the load (unloading), we should allow some extent rock deformation, to give full play to rock the capacity for self. Is an economic support measures, the rock self-stability P=P0-PE=Ku;(3) When u=umax, landslides, have relaxation load and unsafe.4. Points(1). Rock cavern excavation is affected by that part of rock (soil) body, the rock is a trinity : have a load bearing structure, building materials.(2). Tunnel construction is in the rock stress is of special architectural environment, which can not be equated with the construction on the ground.(3). Tunnel structure rock + = bracing system.II. The new Austrian highway construction in the basic methodNATM one of the characteristics is the scene monitoring, measurement information to guide construction, through the tunnel construction measure receipts and excavation of the geological observation for prediction and feedback. And in accordance with the established benchmark for measuring the tunnel construction, excavation section steps and sequences, Supporting the initial parameters for reasonable adjustments to guarantee the safety of construction, a tunnel rock stability, the quality of the project and supporting structure of theeconomy and so on. The author of commitments (Chengde) Chek (Chifeng) East Maojingba Tunnel NATM basic construction method for investigation concluded, synthesis of a new highway tunnel Natm the selection of different types and the basic characteristics of the construction methods and tips.1. A tunnel construction method of choice tunnel construction method of choice, mainly based on the engineering geological and hydrogeological conditions Construction, rock type, buried deep tunnel, the tunnel section size and length lining types, Construction should be the premise of safety and engineering quality at the core, and with the use of the tunnel function, the level of construction technology, Construction machinery and equipment, time requirements and economic feasibility of factors to consider in selection.When choosing the method for tunnel construction on the surrounding environment negatively affected, should also be a tunnel, the environmental conditions as the method to choose one of the factors, taking into rock changes the method and the applicability of the possibility of change. Tunnel project to avoid mistakes and unnecessary increase investment in public works. NATM new construction, we should also consider the entire process of construction of auxiliary operations and changes in the surrounding rock to measure control methods and the tunnel through special geological lots of construction means for a reasonable choice.2. New Austrian Tunneling Method program New Austrian Tunneling Method used all methods can be divided into sections, Division level and the three major types of excavation method and some changes in the program.(1) Full-face method. That whole section excavation method is based on the design of an excavation face excavation molding. Excavation order is its full face excavation, steel bracing, pouring concrete lining. Often choose to IV-VI Class Rock Hard Rock Tunnel, which can be used blasting deep hole.Excavation whole section of the law is a larger space operations, introducing supporting large mechanized operations, improving the speed and process small, less interference and facilitate the construction organization and management. Excavation is due to shortcomings in the larger, lower relative stability of rock, and with each cycle of the relatively large workload, it requires the construction units should have a strong excavation, transport and slag out andsupport capability, Maojingba VI : Class V rock used in the full-face excavation to achieve the desired results.Full-face excavation face, drilling and blasting construction more efficient use of deep focus to accelerate the excavation blasting speed, and the rock blasting vibration frequency less conducive to a stable transfer rocks. The drawback is every deep hole blasting vibration larger. Therefore require careful drilling and blasting design and strict control of blasting operations.Full-face excavation method is the main process : the use of mobile carts (or platforms), the first full-face a bored, and installed a line, and then drilling platform car outside 50m back to a safe place and then detonate, Blasting to make a shape out after drilling Jardine car again moved to the excavation face in place, began a cycle of drilling and blasting operations, Anchor sprayed simultaneously supporting or after the first arch wall lining.(2) step method. Step method of design is generally divided into sections on the half-section and the lower half section two excavation molding. Excavation order is its first half excavation arch bolt jet concrete bracing, arch lining, the central part of the second half of excavation, sidewall of excavation, concrete wall jet bolt support and lining. The more applicable to the II, III and soft joint development of the surrounding rock, which were used Tim change program.Long-step method : The next stage distance away, on the general level above 50m ahead, Construction can be assigned to the Department of next larger machine with parallel operations, when mechanical deficiencies can be used interchangeably. When the case of a short tunnel, the upper section will be all dug later, and then dug under the section, the construction of which less interference, single process can work.Short step method : on the stage length 5-50m apply to Ⅱ, Ⅲrock can be shortened Invert closing time, Supporting improve early stress conditions, but larger construction interference, in the event of Soft Rock need to consider carefully, Auxiliary shall be applied measures to stabilize the excavation excavation face, in order to ensure the safety of construction.Ultrashort step method : The only step ahead 3-5m, section closed faster. The method used for the high level of mechanization of various rock section, in the event of the siege softrock when required careful consideration. Auxiliary shall be applied measures to stabilize the construction excavation face to ensure the safety of construction.Excavation level of character is the first step to using light excavation drilling machine drill a hole, rather than through large drilling platform car. Two step method of excavation operations with sufficient space and a faster rate of construction. Level is conducive to the stability of excavation face. Especially Excavation in the upper, lower operational safety. Three step method of excavation is the next shortcomings of operations interfere with each other. It should be noted at the bottom of the upper operational stability, level of excavation will increase the number of country rock.(3) Segment excavation method. Excavation Law Division can be divided into five changes in the program : Excavation Division level, from top to bottom hole lead, heading advance on the excavation, single (double) and lateral pit method. Excavation will be conducted Section Division excavation by the Ministry of shape, and to advance some of excavation, it may be called derivative ahead excavation pit method.Law Division level : general application or soil collapse easily lots of soft rock, with its advantages - stage method, height can be lengthened, the two-lane tunnel for a hole-fold, cycling Road Tunnel - hole 2 times; rather than single (double) PENDANTS Heading a high degree of mechanization, can accelerate the progress of the projects.The next heading advance excavation method (that is guided pit wall first arch) : This Act applies to Ⅱ, Ⅲrock. in the soft ground tunneling, to be adopted next general guide advance excavation pit wall first arch Act. Its advantages are : Heading advance excavation, the use of proven geological conditions in advance to facilitate change in the method. Face to facilitate started procedures applicable to the labor arrangements for the use of small machinery and construction. The drawbacks : The next section will guide small, slow construction and construction processes more, construction and management difficult.Unilateral-arm pit Law : rock instability, the tunnel span larger, ground subsidence is difficult to control when using this method. Its characteristics are : a positive step and arms Heading Act advantages.Bilateral arm Heading law : in large-span shallow tunnels, surface subsidence require strict, especially poor rock used. Advantages of this method are : Construction of safe, reliable, but slow construction, high cost.III.The main tunnel construction technology1. Cave construction(1)excavation slope aroundLofting total station measurements, the use of excavators from top to bottom, paragraph by paragraph excavation, not the amount of excavation or the end of next overlapping excavation, remove pits with the above may slump topsoil, shrubs and rock slopes, rock strata of slope excavation needs blasting, Discussion should focus mainly loose blasting. Also partial artificial finishing, when excavation and inspection slope of slope, if sliding and cracking phenomenon and slowing down due slope.(2).Cheng Tung-supportingYang Brush Singapore Singapore after the completion of timely inspection plate slope gradient, the gradient to pass the inspection, the system set up to fight time anchor, and the exposed bolt heads, hanging metal based network expansion and bolt welding into first overall. Linked network immediately after the completion of shotcrete and repeatedly jet until it reaches the thickness of the design so far.(3).as of gutter constructionYang slope away from the groove 5 meters excavation ditch interception, interception gutter mainly mechanical excavation, artificial finishing, after dressing, 7.5# immediately masonry made of mortar and stones, and the floor surface with mortar.2. Auxiliary construction(1)A long pipe roofSets arch construction : construction Lofting, template installation, assembling reinforcement, the guidance of lofting 127 installation guide, concrete pouring.Pipe specifications : Heat Nazarbayev Seamless Steel Tube ¢108 mm and a thickness of 6 mm, length of 3 m, 6 m;N pipe from : Central to the distance 50 cm;N Inclination : Elevation 1 ° (the actual construction works by 2 °), the direction parallel with the Central Line;N pipe construction error : Radial not more than 20 cm;N tunnel longitudinal joints within the same section with more than 50% adjacent pipe joints staggered at least a meter.A. pipe roof construction methodLofting accurate measurement personnel, marking the centerline and the vault out of its hole elevation, soil excavation reserved as a core pipe roof construction work platform Excavation footage of 2.5 meters, after the end of excavation, artificial symmetrical on both sides of excavation (Commodities H) platform, level width of 1.5 meters, 2.0 meters high, as construction sets and pipe arch shed facilities drilling platform. Pipe-roof design position should be and it should be a good hole steel tube, grouting after playing non-porous tube steel, non-porous tube can be used as pipe inspection, Grouting quality inspection, drill vertical direction must be accurately controlled to guarantee the opening hole to the right, End each drilling a hole is a pipe jacking, drilling should always use dipcompass drilling pipe measuring the deflection, found that the deflection over design requirements in a timely fashion. Pipe joints using screw connection, screw length 15 cm, to stagger the pipe joints, odd-numbered as the first section of the introduction of three-meter steel pipes and even numbered the first section of pipe using 6 meters, After each have adopted six-meter-long steel pipe.B. pipe roof construction machineryN drilling machinery : XY-28-300 equipped with electric drill, drilling and pipe jacking long shelf;N grouting machine : BW-250/50-injection pump two Taiwan;N using cement-water glass slurry. Mud and water volume ratio 1:0.5; water glass slurry concentration of water-cement ratio 1:1 silicate 35 Baume; The efficacy silicate modulus pressure grouting pressure early pressure 2.0MPA 0.5~1.0MPA; end.(2). a small catheterA. small catheter used ahead diameter of 42 mm and a thickness of 3.5 mm thermal Nazarbayev seamless steel tubes, steel pipe was front-tip, Welding on the tail ¢6 stiffening brace and the wall around the drilling hole grouting 8 mm, but the tail of a meter without grouting holes and Advance Construction of a small catheter, the tubes and the lining of the centerline parallel to 10 ° -30 ° Chalu into the rock arch. penstocks to 20-50 cm spacing. Each was over a steel tubes, should be closed immediately shotcrete excavation face and thengrouting. After grouting, erecting steel Arch, Supporting the early completion of every (2-3 meters, and the paper attempts to be) another one for steel tubes, Advance small catheter general lap length of 1.0 meters.B. Grouting parametersN water slurry and water glass volume : 1:0.5;N slurry water-cement ratio 1:1N 35 Baume concentration of sodium silicate; The efficacy silicate modulusN grouting pressure 0.5~1.0MPA; if necessary, set up only orifice Pulp Cypriots.(3). bolting ahead : The Chalu must be greater than 14 degrees, grouting satiated and lap length is not less than 1 meter.3.Correcting constructionEmbedded parts used by the Design Dimensions plank make shape design, installation in contrast snoop plate car, and position accuracy (error ± 50CM), the firm shall not be fixed, you must be in possession of the wire through the middle wear.4. Leveling ConstructionInstallation templates, at the request of both sides leveling layer calibration position to install template. Side-channel steel templates used [10#, top elevation with a corresponding length of the road elevation unanimously to allow deviation ±2mm. adjusted using the standard measurement to determine elevation. Every template fixed a certain distance from the outside to ensure that no displacement, the joints template close comfort, not from a slit, crooked and formation, and the bottom connector templates are not allowed to leak plasma. Concrete before reperfusion, the bottom surface of concrete must be clean. When the concrete arrived at the construction site directly installed backward mode of the road bed, and using artificial Huabu uniform. Concrete paver should be considered after the earthquake destroyed the settlement. Unrealistically high can be 10% higher, Lan is the surface elevation and design line. Concrete earthquake destroyed at or anywhere near the corner with plug-Lan Lan pound for pound order; Flat-Lan pound for pound crisscross comprehensive Lan, Inside each location is no longer the time for concrete sinks, no longer emitted large bubbles, and the surface of cement mortar later. normally no less than 15 seconds, also should not be too long;Then Chun-pound beam along the longitudinal Lan-pound trailer, With redundant Chun-pound concrete beams were dragged shift Trim, Dixian Department should keep leveling Lan facts. Finally, the diameter 75~100mm rolling seamless steel pipe for further leveling. Just do prohibited in the surface spraying water, and threw cement.5. Water, cable duct constructionInstall groove wall reinforcement of location accuracy, the line must be linked to the construction. Install groove wall purity, the purity requirements of accurate location, a vertical line. Dyadic greatest degree of not more than 3 mm, and template-Ditch The top-pronged, pass the inspection before the concrete reperfusion, on the side of the original wall must pick hair, and embedded parts to the location accurately. Template using stereotypes purity.6.Gate ConstructionCleared the site for construction layout. By design size requirement dug-wall basis. M7.5# masonry made of mortar and stones.Template installation, location accuracy requirements purity, a vertical line, and timely inspection template slope. Concrete pouring 15 # Riprap concrete, concrete strength to be more than 70% for Myeongdong vault backfill.Myungdong vault backfill should hierarchical compaction said. The typical thickness of less than 0.3M, both backfill surface height difference of not more than 0.5M. restored to the vault after the pack to design hierarchical compaction high, the use of machines rolling, Ramming must manually filled to vault over 1.0M before mechanical compaction .7 .Construction safety and environmental controlEntrance to wear helmets to prevent crashes, in which the speed limit 5KM, lighting must be a 10-meter lights reckless goods stored material must be standardized and distributed under special guard.Spoil venues must be smooth drainage, and must be masonry retaining wall to prevent flooding, debris flow forming.8. The construction process has to tackle the problemsConstruction of two liner after water seepage treatment :Small cracks with acrylic, water or slurry coating of epoxy resin and other caulking, a good effect; On the larger cracks, available on the 10th of cement mortar or cement mortar expansion caulking more appropriate and effective;Large cracks (crack width greater than 5MM), (if leakage of water, available along the cutting machine cutting a wide cracks around 2~4CM small groove depth approximately 10CM above the water, Cutting a 5 × 5CM Cube holes room, then insert a pipe 4 × 4CM MF7 plastic Blind groove, Cutting together into good pressure tank, the introduction of vertical water drains, Finally, cement and water Glass closed mixed mortar cutting groove) without seepage, it is appropriate epoxy mortar, or grouting, Reinforced concrete and other reinforced jet.IV. Example projectsNATM is from the introduction of the bolt and shotcrete a category of "active" support the new technology to promote the use began. Soon, the Chinese engineer on the tunnel not only in substance but also in terms of acceptance of the new Austrian law. To be held in China in the tunnel and underground engineering academic meeting, the new Austrian capital has become a hot topic.Engineers of the new Austrian law relishes is justified : the use of new Austrian law, has been successful in soft rock and difficult conditions of the construction of various types of underground works.Built on loose sand gravel stratum of Beijing Subway allowed back of the tunnel is a typical example. The tunnel is located in the main street-256, 358m long, the largest excavation section 9m high, 14.5m wide coverage stratigraphic top of the tunnel only minimum thickness 9.0m. Tunnel boring machine of excavation, strengthen the grid arch shotcrete initial support and advance small catheter care, Without prejudice to ground transportation, underground pipelines to ensure the safety of construction success.In the works is the experience, knowledge of the Chinese engineers, the use of new Austrian law principles can be used in the Mountain Tunnel Mine Act to expand the scope ofapplication of the soft rock, even in the fourth strata of municipal shallow tunnel to replace the traditional method of digging or shield. In China, such a method called "shallow mining method."Following allowed back lane tunnel, gravel in the same folder of alluvial gravel layer is shallow mining method used to build the span of 21.67m in the Xidan MTR stations.Changan Avenue in the construction of the new Beijing metro line projects, shallow mining method has been selected as the main method of construction. For example, the Tiananmen Square in Beijing Metro West Point, 226m long, for two double-pole structure.Guangzhou Metro East is shallow mining method used in the construction. Experience shows that from the ground environmental protection, surface subsidence of the dug system and the cost and time period perspective, Shallow Mining Act of open or with the shield are compared with a competitive edge.Chinese engineers from Europe to the introduction of the new Austrian law, and in light of China's situation of the new Austrian law, and related technology expanding means of support, such as, measurement and control technology was further developed. As a new Austrian law an important background shotcrete technology in China has been widely used. With the international situation, in order to resolve the long-troubled people of dust pollution of the environment. Rebound serious and concrete uneven quality of such issues, and is vigorously implementing the wet spray. Recently by the China Academy of Railway Sciences Southwest Branch of the development of a "Rotor-Piston," a new type of jet aircraft. This type wet spraying process, which is to include the machines Mix Concrete Preparation good product mixture, However, material handling is different from the general-pumping wet spraying machine, using thin stream conveyor. Therefore machines compact and easy to use. Has been popularized in this country.It is no exaggeration to say that the new Austrian law implementation has indeed caused a mining method in the construction of the excavation, Construction of the tunnel design, and even the thinking of the major changes. Nevertheless, it should be said that China's implementation of the new Austrian law is not satisfactory. In many works was no lack of examples of failure. In addition to construction management, quality control and technology related to grasp, and other reasons, is the main tunnel engineers sometimes NATM real lack of a proper understanding.。

地下空间开发的新技术和新理念

3. 地下工程设计新思维 3.3 防水设计的新趋势 管片衬砌接缝防水:

我们的国际专利: 利用遇水膨胀条的空隙,采用磁条固定防水条和钢膜。

26

3. 地下工程设计新思维

3.4 管片设计的新趋势 开发新型螺栓(销钉)连接方式

CROSSRAIL PROJECT 手孔尽可能地小

27

3. 地下工程设计新思维

1. 地下空间开发的挑战

关于信息化的挑战

3). 上海申通的体会: 首先明确决策需求和内容,从而确定信息采集的需求; 在线监测的数据必须要有运营维护人员实时处理; 建立统一的技术标准, 不同的BIM设计单位建立的数据模型就能实现协同, 并被传递、应用到运营维护阶段, 发挥BIM技术在工程全寿命周期应用的优势。

21

3. 地下工程设计新思维

3.2 TBM隧道

衬砌: 1.铸铁管片(寿命200年) 2.钢管片(寿命50-70年) 3.钢筋混凝土管片(寿命120年) 4.复合管片

22

3. 地下工程设计新思维

3.2 TBM隧道

未来衬砌: 1. 泡沫聚苯乙烯聚合物混凝土管片(QOR)

75mm厚的强度 = 普通混凝土280mm的强度 2. UHPC

6

1. 地下空间开发的挑战 高风险的挑战(高概率)

即使管片壁后过度注浆也会给地表带来问题

7

2.

地下空间规划新理念

8

2. 地下空间规划新理念

无论在哪个城市,地铁都集中分布于城市中心区域。

9

2. 地下空间规划新理念

中国特色: 建在城市中心的地铁对已建房价有利,

也就是说对老百姓来说利好! 建在郊区的地铁对土地增值有利, 也就是说对地方政府来说利好!

新意大利方法:着眼隧道的三维特性

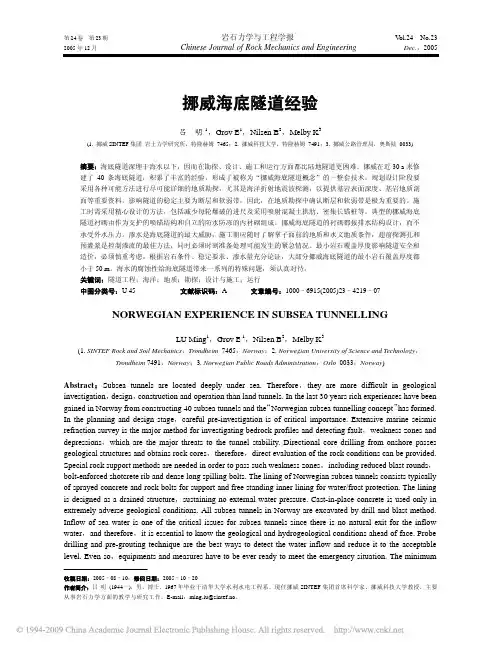

挪威海底隧道经验

表 1 挪威部分海底隧道主要数据[3] Table 1 Key data of some Norwegian subsea tunnels[3]

隧道名称

完工年代 A/m2 岩石种类 L/km h/m H / m

Vardø

1981

53 页岩/砂岩 2.6

28

88

Ellingsøy

1987 68 片麻岩

Abstract:Subsea tunnels are located deeply under sea. Therefore,they are more difficult in geological investigation,design,construction and operation than land tunnels. In the last 30 years rich experiences have been gained in Norway from constructing 40 subsea tunnels and the“Norwegian subsea tunnelling concept”has formed. In the planning and design stage,careful pre-investigation is of critical importance. Extensive marine seismic refraction survey is the major method for investigating bedrock profiles and detecting fault,weakness zones and depressions,which are the major threats to the tunnel stability. Directional core drilling from onshore passes geological structures and obtains rock cores,therefore,direct evaluation of the rock conditions can be provided. Special rock support methods are needed in order to pass such weakness zones,including reduced blast rounds, bolt-enforced shotcrete rib and dense long spilling bolts. The lining of Norwegian subsea tunnels consists typically of sprayed concrete and rock bolts for support and free standing inner lining for water/frost protection. The lining is designed as a drained structure,sustaining no external water pressure. Cast-in-place concrete is used only in extremely adverse geological conditions. All subsea tunnels in Norway are excavated by drill and blast method. Inflow of sea water is one of the critical issues for subsea tunnels since there is no natural exit for the inflow water,and therefore,it is essential to know the geological and hydrogeological conditions ahead of face. Probe drilling and pre-grouting technique are the best ways to detect the water inflow and reduce it to the acceptable level. Even so,equipments and measures have to be ever ready to meet the emergency situation. The minimum

挪威计划建造世界首例“水下悬浮隧道”

Байду номын сангаас

据挪威公路管理局高级工程师阿里安娜(AriannaMinoretti)介绍,这个想法并非疯狂,其具备一定可行性。根据他们的临时方 案,对于深 1.3km、宽 1km的松恩峡湾(Sognefjord)来说,这种出行方案或许是一个绝佳的解决方案。这个水下混凝土管道长达1.2 km,呈弯曲状,内部将具备双向运行车道,管道将被置于水面以下 19~30m处。水面上的浮筒将支撑管道,而桁架与之相连确保其 稳固性;管道也可能被绑在水下的岩基上以增加稳定性。

1148

隧道建设(中英文) 第 38卷

CHEN Shaozhang, SU Zongxian, CHEN Yue. New technologiesusedforimmersedtunnelofHongkongZhuhai MacaoBridgeProject[J].TunnelConstruction,2015,35 (5):396. [13] 高星林,张鸣功,方明山,等.港珠澳大桥工程创新管 理实践[J].重 庆 交 通 大 学 学 报 (自 然 科 学 版 ),2016, 35(增刊 1):12. GAOXinglin,ZHANGMinggong,FANGMingshan,etal. Hong KongZhuhaiMacao Bridge Project creative managementpractice[J].JournalofChongqingJiaotong University(NaturalScience),2016,35(S1):12. [14] 交通运输部.关于港珠澳大桥主体工程初步设计的批 复:交公路 发 [2010]167号 [R].北 京:交 通 运 输 部, 2010. MinistryofCommunicationsandTransportation.Replyto preliminarydesignofmainstructureofHongKongZhuhai

斯堪的纳维亚硬岩海底隧道工程_英文_

第26卷 第11期岩石力学与工程学报 V ol.26 No.112007年11月 Chinese Journal of Rock Mechanics and Engineering Nov.,2007Received date :2007–06–16;Revised date :2007–07–20Corresponding author :GRØV Eivind(1958–),male ,Ph.D.,graduated from Norwegian University of Technology and Science in 1984. Research ManagerSUBSEA TUNNEL PROJECTS IN HARD ROCKENVIRONMENT IN SCANDINA VIAGRØV Eivind 1,NILSEN Bjørn 2(1. SINTEF Rock and Soil Mechanics ,Trondheim 7465,Norway ;2. Norwegian University of Science and Technology ,Trondheim7491,Norway )Abstract :The paper reviews the experiences from Nordic subsea tunnel benchmark projects ,with emphasis on subsea road tunnels excavated in bedrock. More than 25 such tunnels have been built in the Nordic countries ,representing a total length of more than 100 km ,and with the majority of the projects located in Norway. The completed projects include tunnels with length up to 7.9 km and depth below the sea level down to 264 m. All these tunnels have been excavated by methods of drilling and blasting. Important issues concerning investigation ,planning ,design and construction are described ;and important lessons learned from these projects are discussed. Finally ,plans for potential future subsea tunnel projects are presented ,representing tunnel lengths of up to 24 km and depths below sea level down to 400 m. Also subsea tunnel projects in other Nordic countries will be presented as they have been designed and constructed according to Norwegian subsea tunnel principles.Key words :subsea tunnel ;investigation ;planning ;design and constructionCLC number :U 459.5 Document code :A Article ID :1000–6915(2007)11–2176–17斯堪的纳维亚硬岩海底隧道工程GRØV Eivind 1,NILSEN Bjørn 2(1. 森泰福岩土力学,挪威 特隆赫姆 7465;2. 挪威科技大学,挪威 特隆赫姆 7491)摘要:论述了北欧海底隧道特别是基岩中开挖的公路隧道的工程经验,目前在北欧已建成25条以上的海底隧道,总长超过100 km ,大部分在挪威,最长的7.9 km ,最深的在海平面下264 m 。

挪威北海恶劣海况下半潜式钻井平台工作性能分析_韩荣贵

占所有海况数量的百分比。用该百分比表征平台 每年可以工作的时间百分比,作为评价平台运动 性能优劣的参考。百分比越高说明平台可操作的 时间越多,平台工作性能越好。

2 算例分析

将中集来福士正在建造的某半潜式钻井平台 与已建的两座工作于同一海域的半潜式钻井平台 ( 记为 1#平台和 2#平台) 进行工作性能方面的对 比分析。该平台在运动性能优化方面做了进一步 的优化设计。3 座半潜式钻井平台的设计时间先 后顺序依次是 1#平台、2#平台和本平台。

1 工作性能分析介绍

工作性能分析主要是在水动力系数计算基础 上,根据半潜式钻井平台具体操作工况的运动限 制条件,结合实际工作海域的波浪信息,应用短期 预报方法,统计某项操作每年可以工作的时间百 分比。 1. 1 势流理论

采用三维势流理论求解半潜式钻井平台附加

收稿日期: 2015 - 11 - 06 修回日期: 2015 - 12 - 08 基金项目: 山东省自主专项 ( 2014CGZH1202) ; 泰山

船海工程 SHIP & OCEAN ENGINEERING

DOI: 10. 3963 / j. issn. 1671-7953. 2016. 03. 029

Vol. 45 No. 3 Jun. 2016

挪威北海恶劣海况下半潜式钻井平台工作性能分析

韩荣贵,时 磊,杨 楠,崔 娜,李 磊,肖 元,张健效

wp = 2π /Tp

( 2)

式中: Tp———谱峰周期;

HS ———有义波高;

p———波浪圆频率。

通过水动力分析软件获得平台 RAO,结合实

际海 域 的 波 浪 谱,即 可 获 得 平 台 运 动 响 应 谱

SR ( w) [6]。

SR( w) = | RAO | 2Sξ( w)

隧道工程资料:隧道施工新奥法.doc

隧道工程资料:隧道施工新奥法新奥法即新奥地利隧道施工方法的,原文是NewAustrianTunnellingMethod简称NATM,新奥法概念是奥地利学者拉布西维兹(L.V.RABCEWICZ)教授于50年代提出的,它是以隧道工程经验和岩体力学的理论为基础,将锚杆和喷射混凝土组合在一起作为主要支护手段的一种施工方法,经过一些国家的许多实践和理论研究,于60年代取得专利权并正式命名。

之后这个方法在西欧、北欧、美国和日本等许多地下工程中获得极为迅速发展,已成为现代隧道工程新技术标志之一。

六十年代NATM被介绍到我国,七十年代末八十年代初得到迅速发展。

至今,可以说在所有重点难点的地下工程中都离不开NATM。

新奥法几乎成为在软弱破碎围岩地段修筑隧道的一种基本方法。

新奥法是充分利用围岩的自承能力和开挖面的空间约束作用,采用锚杆和喷射混凝土为主要支护手段,对围岩进行加固,约束围岩的松弛和变形,并通过对围岩和支护的量测、监控,指导地下工程的设计施工。

新奥法(NATM)是新奥地利隧道施工方法的简称,在我国常把新奥法称为锚喷构筑法。

采用该方法修建地下隧道时,对地面干扰小,工程投资也相对较小,已经积累了比较成熟的施工经验,工程质量也可以得到较好的保证。

使用此方法进行施工时,对于岩石地层,可采用分步或全断面一次开挖,锚喷支护和锚喷支护复合衬砌,必要时可做二次衬砌;对于土质地层,一般需对地层进行加固后再开挖支护、衬砌,在有地下水的条件下必须降水后方可施工。

新奥法广泛应用于山岭隧道、城市地铁、地下贮库、地下厂房、矿山巷道等地下工程。

当前,世界范围内应用新奥法设计与施工城市地铁工程取得了相当大的发展。

如智利的圣地亚哥新地铁线采用新奥法施工地铁车站,车站位于城市道路下7~9m,开挖面积230m2,相当于17m(宽)14m (高);我国自1987年在北京地铁首次采用新奥法施工复兴门车站及折返线工程,车站跨度达26m。

针对我国城市地下工程的特点和地质条件,新奥法经过多年的完善与发展,又开发了浅埋暗挖法这一新方法,与明挖法、盾构法相比较,由于它可以避免明挖法对地表的干扰性,而又较盾构法具有对地层较强的适应性和高度灵活性,因此目前广泛应用于城市地铁区间隧道、车站、地下过街道、地下停车场等工程,如根据新奥法的基本原理,采用群洞方案修建的广州地铁二号线越秀公园站及南京地铁一期工程南京火车站站,断面复杂多变的折返线工程、联络线工程也多采用新奥法。

新奥法即新奥地利隧道施工方法的简称

新奥法即新奥地利隧道施工方法的简称,原文是New Austrian Tunnelling Method 简称 NATM ,新奥法概念是奥地利学者拉布西维兹(L. V. RABCEW ICZ)教授于 50 年代提出的,它是以隧道工程经验和岩体力学的理论为基础,将锚杆和喷射混凝土组合在一起,作为主要支护手段的一种施工方法,经过一些国家的许多实践和理论研究,于60年代取得专利权并正式命名。

目录•1简介 2发展历史 3支护机理 4施工原理 5主要原则 6施工特点 7施工要点 8施工顺序 9适用范围 10详细解释 11过程 12基本观点 13基本要点 14施工量测 15实际使用 16缺点 17展望未来1简介新奥法【New Austrian Tunnelling Method】新奥法是在利用围岩本身所具有的承载效能的前提下,采用毫秒爆破和光面爆破技术,进行全断面开挖施工,并以形成复合式内外两层衬砌来修建隧道的洞身,即以喷混凝土、锚杆、钢筋网、钢支撑等为外层支护形式,称为初次柔性支护,系在洞身开挖之后必须立即进行的支护工作。

因为蕴藏在山体中的地应力由于开挖成洞而产生再分配,隧道空间靠空洞效应而得以保持稳定,也就是说,承载地应力的主要是围岩体本身,而采用初次喷锚柔性支护的作用,是使围岩体自身的承载能力得到最大限度的发挥,第二次衬砌主要是起安全储备和装饰美化作用。

2发展历史1934年,新奥法主要创始人 L.V. 拉布采维茨在就试图将喷浆方法用于地下工程。

他在1942~1945年建造的洛伊布尔隧道中采用了双层薄衬砌,即先喷一层混凝土,待变形收敛后再喷一层。

1944年,他发表了有关喷混凝土的论文,并指出了围岩动态随时间变化的重要性。

1948年,又指出了量测工作的重要性。

又无公害的新喷敷方法1948~1953年喷混凝土在奥地利首次用于卡普伦水力发电站的默尔隧洞。

最早在欧洲推广使用锚杆的是1951~1953年建造的伊泽尔-阿尔克电站的有压输水隧洞。

德国籍隧道专家崔旭东博士新奥法设计原则与中德隧道技术标准讲座统计学

开挖的形式(包括截面、进尺)及支护形式 动态施工:测量是新奥法不可缺少的组成部分

New Austrian Tunneling Method (NATM)

HK PDL JX JL4 沪昆

HK PDL JX JL4 沪昆

新奥法之父

新奥法F在ra6n0z年P代ac由he这r 三位(帕前赫辈)专家创始并发展 奥地利岩土力学及隧道专

家,特别是

Kalman Kovari (科瓦利)

瑞士岩土力学及隧

道(1专91家9—

)

新奥法的创始

人及发展者之一

(1937—

)

Bernhard Maidl (迈德尔)

德国隧道专家

New A(u19s3t8r—ian Tunn)eling Method (NATM)

HK PDL JX JL4 沪昆

新奥法的应用及发展

支护机械: 钻爆作业宜采用液压凿岩台车

支护机械: 喷射混凝土应配置湿喷机……, 双线及多线隧道宜选用喷射混凝土台车

New Austrian Tunneling Method (NATM)

HK PDL JX JL4 沪昆

新奥法的应用及发展 开挖机械: 钻爆作业宜采用液压凿岩台车

New Austrian Tunneling Method (NATM)

HK PDL JX JL4 沪昆

新奥法的应用及发展 Sohlgewoelbe 仰拱施工

NSacnhibeerhuanngdslwuanggesnwagen 二衬养表护面车美容及拱顶注浆车

New Austrian Tunneling Method (NATM)

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

挪威法NTM Norwegian Methodof Tunneling第一部分概述最近,大家对挪威法议论纷纷,究竟挪威法是什么?,其内涵如何?挪威法(NTM)与新奥法(NATM)有何区别?等等,本文根据有关文献作一简要说明。

挪威法,简单地说,是由正确的围岩评价、合理的支护参数选定及高性能的支护材料三部分构成的一种经济而安全的隧道施工方法。

它适用于铁路隧道、公路隧道、水工隧洞及大型地下岩石工程。

正确的围岩评价主要是采用Q系统,即:巴顿法(N·Barton)进行围岩分级。

而合理的支护结构参数,最后是通过施工中的观察和量测记录求出的Q 值来选择的,其中包括各种支护体系的数值解析检验。

在支护体系上的最大特点是把一次支护作为永久支护,即我们目前所谓的单层衬砌。

只是在运营后,如果有涌水,冰霜等危害的情况下,才修筑二次支护(衬砌)。

通常永久支护是采用高质量的(σck=40~50MPa)的钢纤维喷射混凝土和全长胶结型高拉力、耐腐蚀的锚杆。

根据挪威的经验,采用挪威法修筑断面积为45~110m2隧道的建筑费用是4000~8000美元。

因不施作二次支护(衬砌),其混凝土量比NATM小,约为NATM的1/2~1/5。

因此,工期也得以缩短。

图1 NMT的设计和方法下面简要说明NMT的基本内容和方法。

1、设计·预设计基于现场调查、钻孔调查(室内试验)及弹性波探查;·围岩分级通常采用Q法进行评价;·各种支护模式的数值解析验证多采用不连续体解析的UDEC-BB、3DEC方法进行;·最终的支护设计根据施工中的观察和量测记录求出的Q值选定支护模式;·NMT一次支护作为永久支护一部分,使用开始后的漏水对策、冰霜对策可采用混凝土板或钢板施设二次衬砌2、开挖与支护·开挖视围岩状况采用爆破或机械方法进行;·局部锚杆、系统锚杆、系统锚杆+钢纤维喷混凝土构成的一次支护作为永久支护一部分;·永久支护的支护模式,边施工边选定;·通常,永久支护由高品质(σck=40~50MPa)钢纤维喷混凝土和全长附着型、高拉力、耐腐蚀的锚杆构成。

二、围岩评价——Q值Q值围岩评价法是70年代初由N·Barton提出的一种围岩分级方法,在欧洲等国应用较广。

由于最近20几年支护技术的发展,特别是高质量的钢纤维喷混凝土的开发,取得了很大的进展。

但作为挪威法基本特征之一的Q系统围岩评价法变化不大,而仅仅是作为围岩应力的变量SRF,考虑到埋深增加时的岩爆及软岩的膨胀性等,其范围值扩大了。

Q值把围岩分为6级(0.001~1000),反映了较为广泛的围岩条件(从膨胀性围岩、未固结围岩到裂隙不发育的整体围岩)。

围岩的变形系数分为3级(0.05~50GPa),抗剪强度分为2级(0.1~20MPa)。

根据这些变量可以求出Q值。

Q值是由下述6个变量组合而成的。

(1)式中 RQD/Jn--相对块度尺寸Jr/Jn--块体间摩擦系数Jw/SRF--有效应力6个变量示于图2的右侧。

此图表示出各变量的变动范围(例如Jn-0.5~20)并做了简要说明(例如裂隙数为1、2、3时,Jn分别为2、4、9)。

左侧的图示说明各级别中频率高的值的组合情况。

因为,即使是同一种岩石学相同的围岩,因现场条件围岩的状态也会有所变化。

因此,数据的统计处理是非常重要的。

图2的Q值判定卡是根据对隧道周边围岩性质的统计处理和RQD的补充数据编制而成,实用性很强。

图2 决定Q值的判定卡三、Q系统的经验支护设计经验设计方法示于图3。

图3 决定Q系统支护设计参数的方法图3的横轴表示Q值,围岩级别表示在上侧。

这里记述的是基于挪威围岩好坏的评价基准。

纵轴是隧道宽度或高度被所谓的安全系数ESR除之值,单位为m。

干线公路隧道、铁路隧道及水力发电用的隧洞的ESR是0.9~1.1。

水工隧洞的ESR是1.6~2.0。

ESR随支护规模而变,因此,费用和安全性也会变化。

现以具体例子说明图3的用法。

图中的●表示宽18m的公路隧道(ESR=1.0),Q值=2.0的例子。

永久支护的规模,根据图3,B1.9m+S(fr)10cm其中:B表示系统锚杆,1.9m间距(横向),S(fr)表示钢纤维喷混凝土,厚度10cm。

系统锚杆的平均长度,根据图3的右纵轴,选定5m。

但最终的锚杆长度和锚杆轴力(破断强度)的推定,要进一步进行详细的设计。

要注意的是,本表的支护参数是以高品质、早强度的钢纤维喷混凝土和高拉力耐腐蚀的锚杆为前提的。

四、Q值和各试验数据(弹性波速度V、σr、变形系数)的关系基于在埋深比较浅的硬质围岩的弹性波速度的数据,图4的上图表示出P 波速度和Q值的关系。

图中也表示出与RQD和裂隙率(F/m)的关系。

图4的下图表示出埋深、围岩裂隙率、弹性波速度和Q值的最近的研究成果。

下面举例说明图4的用法。

图4 V和Q值及变形系数的关系例一1)设定Q=2,即:Qr=1(钻孔岩心),σc=50MPa(JⅡ级围岩:C(b)的砂岩)。

2)设定空隙率n=10%,埋深H=100m3)结果,根据此图,假定围岩的弹性波速度为Vp =3.5km/s。

例二1)设定Q=1、σc=10MPa,即:Qr =0.12)设定空隙率m=5%,埋深H=100m3)根据此图的上侧,Qr=0.1、埋深H=100m时,从左纵轴知,Vr=3.7km/s。

从图的下侧,n=5%时,Vr减少0.8km/s。

因此,Vr =3.7-0.8=2.9km/s,变形系数M(meam)=6.5GPa。

五、NMT的数值解析汇集于图3的Q系统支护设计,已经提供出锚杆的间距和长度、钢纤维喷混凝土的喷射厚度的数值,但在恶劣的围岩条件下,也推荐采用与钢筋肋并用(RRS)的一次支护或者修筑预应力混凝土板的二次衬砌(CCA)。

此设计方法基本上是经验性的。

为了掌握潜在的破坏形态和作用荷载的各向异性以及改善经验设计法,要很好利用数值解析方法。

如图7所示,Q值低于0.1以后,鉴于是裂隙非常多的围岩,非常适用于有限单元法的连续体模式。

而Q值在0.1~100之间采用能够考虑裂隙的不连续体模式的DEM法比较合适。

在埋深极大的整体状围岩中,预测岩爆时,当然有限单元法和BEM法等连续体模式比较合适。

图7 解析方法与Q值的关系图8是修筑在花岗岩中的隧道的解析例,其中6个图表示解析结果。

最近,在UDEC-BB中,也开发出全面交结型锚杆和钢纤维喷混凝土的模式技术。

用图9的极度超挖例加以说明。

图8 采用UDEC-BB方法的解析例图9采用UDEC-S()方法的钢纤维喷混凝土的解析例上图中表示出裂隙的形态和粗糙的开挖面(Jn=12),开挖面的粗线表示喷混凝土。

下图表示喷射后的喷混凝土轴力。

图10 挪威法隧道衬砌例第二部分 Q系统和关键技术一、Q系统的围岩分级裂隙岩体中隧道的稳定性与直接控制裂隙和超挖的裂隙粗糙度有关。

一般的经验指出:埋深或围岩的初始应力低的场合,或者围岩强度高的场合,特别明显。

图1是基于有关工程、裂隙模式及裂隙粗糙度等用图表示的关系。

除节理数(Jn )及其粗糙度(Jr)外,还考虑了对隧道稳定性有影响的第3个要素——夹在裂隙中的粘土。

围岩是否变质,可以用考虑风化作用的(Ja)以及相对的岩块尺寸、应力状态、围岩强度及水压或涌水量等,这些都是用(1)式表示的基本项目。

图1 围岩节理数和粗糙度的影响概念图图2是1986年及1993年两个更新后的支护选定卡。

根据围岩等级决定支护的规模和水准。

Barton等(1974)最初提出的Q系统的当时,支护主要是采用网喷混凝土S(mr)。

1978年以后,钢纤维喷混凝土S(fr)已作为商品投入使用,到1984年已完全代替了S(mr)。

图2所示的更新后的支护选定卡就表现了这样的实质性的变化。

图2 Q系统的支护设计卡1993年又根据图2的1250个事例提供了详细的支护量的规格(图2的下图)。

此卡与1974年提出的大致相同,但因考虑膨胀性围岩和岩爆等地应力问题,其SRF的内容多少有些变动。

二、Q值的利用方法NGI(挪威岩土工程学会)经常使用的方法示于图3、4。

图3 施工中的使用方法图4 根据试样及试坑决定Q值卡图3是两座隧道数据的调查记录。

其中一座是水力发电用的断面积160m2的引水隧洞(左),一座是直径3.3m的TBM掘进的下水道隧道(右)。

根据记录的围岩状态选定的支护是永久支护。

图4是根据约250m的钻孔岩心的Q值(4个浅孔用白色表示)及挪威的地下奥林匹克体育场附近的既有空洞的Q值(黑色)表示的围岩状态。

三、自稳性围岩的特性在硬质围岩为主的许多国家中,隧道施工时,经常会有无支护的地段,这可以节省大量的施工费用。

而且,从安全性、外观、及照明等观点看,还存在潜在性的费用削减,特别是对公路隧道。

因此,研究自稳性围岩的典型特征是很必要的。

这表示在图2的下方。

30个以上的无永久支护的地下开挖的实际,列于表2。

表2 永久无支护的条件1、Jn≤9,Jr≥2、如RQD≤40,则Jn≤2表2所示的Q变量的直接解释,可参考表1.例如表2的项目3『如J=9,J≥1.5及RQD≥90』就是意为着节理有3组存在的场合(J=9),为进行无永久支护的开挖,围岩的J值要在1.5以上(粗糙、平面),RQD值至少在90%(非常好)以上。

表2的条件是理论上的,如不满足就要进行围岩补强。

五、隧道支护的选定图2的支护选定卡中,一次支护和二次衬砌是由表示Q值(0.001~1000范围)的x轴和表示隧道宽度(1~100m范围)的y轴构成的。

但隧道尺寸随表3表示的安全系数ESR而变。

表3 各种洞室的安全系数ESR洞室类型EA 矿山临时巷2例如远离动力室的引水隧洞和矿山采掘场非入口地段一样容许一定程度的掉块,ESR取1.6~2.0,而铁路隧道或者发电站的重要隧洞要保证绝对防止落石,ESR采用0.5~1.1。

1974年初期提出的支护选择表大体上可有38种支护形式的选择。

但根据更新后的图2,可在表4的9种类型中选择。

表4 NMT的永久支护类型支护模式1、无支护图5 钢筋肋、钢纤维喷混凝土支护示意图带有钢筋肋的钢纤维喷混凝土的支护类型(表4中的8)示于图5。

加设钢筋肋的钢纤维喷混凝土是在围岩条件极差的条件下用刚性支护直接支护围岩的较好的方法,根据量测结果和对围岩动态的观察记录可以调整其厚度和间距,同时也可以设置模筑混凝土的二次衬砌。

在奥斯陆的城市隧道中,已经采用了这种形式的支护。

同样地,早期设置与围岩直接接触的支护的重要性在图6的曲线上也得到了反映。

图6 围岩与支护的相互影响概念及松弛的安全系数的关系围岩的松弛系数SRF,在围岩差的情况和支护设置较迟的情况时,会有很大的增加。

而使用过去的钢支撑,因与围岩接触不好,而不能承受较大的荷载,这是使用RRS的主要原因。