【机械类文献翻译】自动洗碗机的控制系统设计

-1-

Automatic dishwasher Control System Design

Abstract:Based on the functional requirements of the automatic dishwasher,introduced by SCM AT89LS8252and keyboard /display management chip designed automatic dishwasher HD7279A hardware control system design methods,using HD7279is given control of the keyboard and display hardware circuit,while the system is functional software modules and software flow chart.After debugging test of the system,which can effectively achieve the control dishwasher complete automatic water,heating,cleaning and disinfection,and other functions.

自动洗碗机的控制系统设计

摘要:基于自动洗碗机的功能要求,介绍了用单片机AT89LS8252和键盘/显示管理芯片HD7279A设计的自动洗碗机的硬件控制系统的设计方法,给出了用HD7279控制键盘和显示的硬件电路,同时给出了系统软件和功能软件模块的流程图。该系统经过试验调试,可有效地实现洗碗机的自动控制,完成自动进水、加温、清洗、消毒等功能。

关键词:洗碗机;控制器;键盘/显示

Key words:dishwashers;controller;keyboard /display

1Introduction

As digital application of information appliances,dishwashers have broad access to masses of people in the family,so that people can work from home in the complex gradually

liberated.

1引言

随着数字信息家用电器应用的普及,洗碗机已经广泛进入人民大众的家庭之中,从而使得人们能够从繁杂的家务劳动中逐步解放出来。

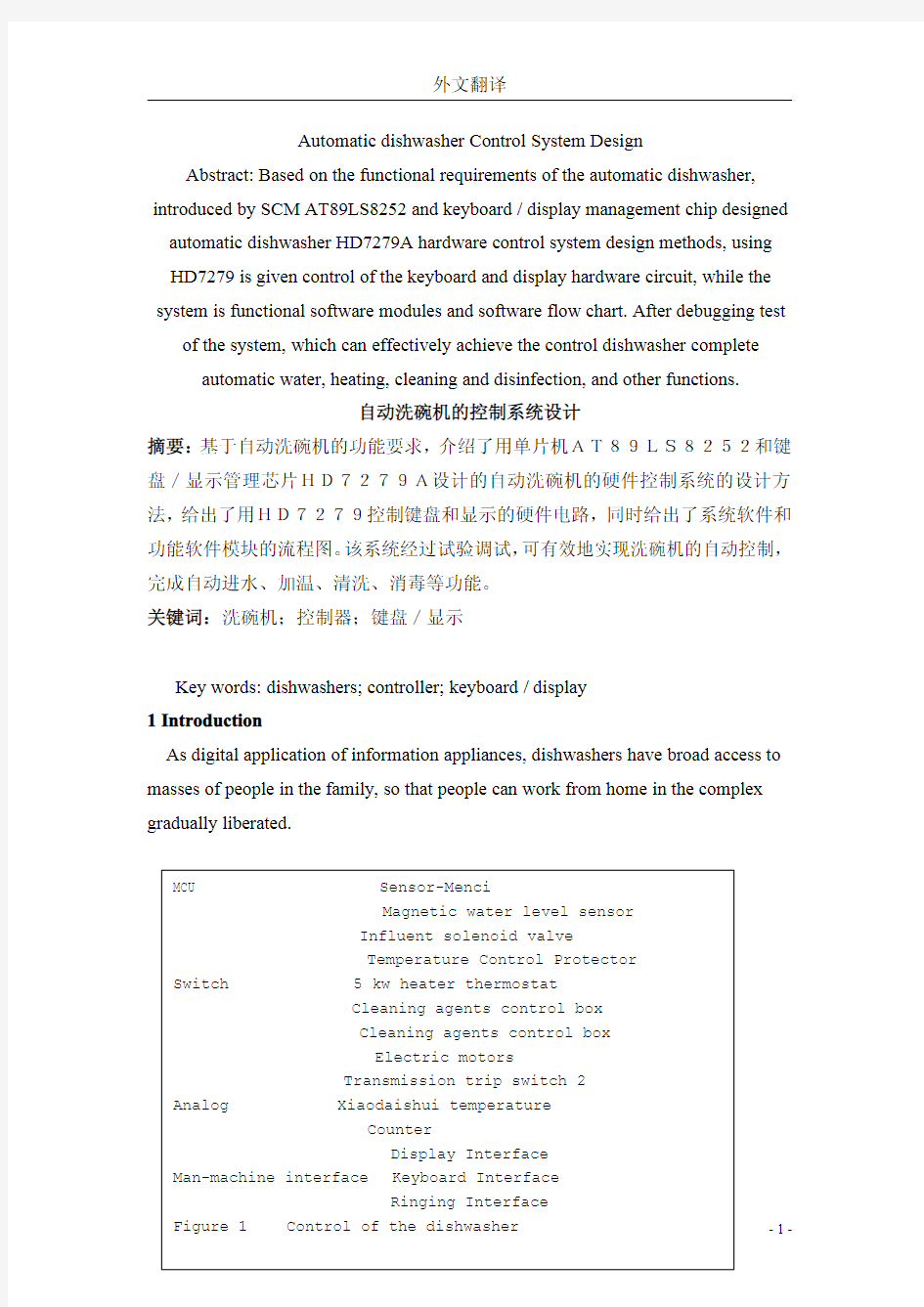

As a home automation equipment,such as dishwashers generally need to a chieve automatic control influent,automatic detergent,cold wash,automatic tem perature washing,cleaning,drainage,Disinfection,and the timing and fault alar m functions.From the point of view of control,a dishwasher usually need to meet Figure1shows some of the specific requirements,which involves the sw itching of signals there are two kinds of sensors is high,low signal detection, such as doors Switch,the water level and temperature regulation for the prote ction of trip switches,etc.;another solid-state relay switching control signals b y the strength of the signal voltage disconnect and loading,such as electromag netic inlet valve opening and closing,opening and closing the heater thermostat ,and instantly the heater to create a control box cleaning agents and disinfect

-2-

关于力的外文文献翻译、中英文翻译、外文翻译

五、外文资料翻译 Stress and Strain 1.Introduction to Mechanics of Materials Mechanics of materials is a branch of applied mechanics that deals with the behavior of solid bodies subjected to various types of loading. It is a field of study that i s known by a variety of names, including “strength of materials” and “mechanics of deformable bodies”. The solid bodies considered in this book include axially-loaded bars, shafts, beams, and columns, as well as structures that are assemblies of these components. Usually the objective of our analysis will be the determination of the stresses, strains, and deformations produced by the loads; if these quantities can be found for all values of load up to the failure load, then we will have obtained a complete picture of the mechanics behavior of the body. Theoretical analyses and experimental results have equally important roles in the study of mechanics of materials . On many occasion we will make logical derivations to obtain formulas and equations for predicting mechanics behavior, but at the same time we must recognize that these formulas cannot be used in a realistic way unless certain properties of the been made in the laboratory. Also , many problems of importance in engineering cannot be handled efficiently by theoretical means, and experimental measurements become a practical necessity. The historical development of mechanics of materials is a fascinating blend of both theory and experiment, with experiments pointing the way to useful results in some instances and with theory doing so in others①. Such famous men as Leonardo da Vinci(1452-1519) and Galileo Galilei (1564-1642) made experiments to adequate to determine the strength of wires , bars , and beams , although they did not develop any adequate theo ries (by today’s standards ) to explain their test results . By contrast , the famous mathematician Leonhard Euler(1707-1783) developed the mathematical theory any of columns and calculated the critical load of a column in 1744 , long before any experimental evidence existed to show the significance of his results ②. Thus , Euler’s theoretical results remained unused for many years, although today they form the basis of column theory. The importance of combining theoretical derivations with experimentally determined properties of materials will be evident theoretical derivations with experimentally determined properties of materials will be evident as we proceed with

驱动桥外文翻译

驱动桥设计 随着汽车对安全、节能、环保的不断重视,汽车后桥作为整车的一个关键部件,其产品的质量对整车的安全使用及整车性能的影响是非常大的,因而对汽车后桥进行有效的优化设计计算是非常必要的。 驱动桥处于动力传动系的末端,其基本功能是增大由传动轴或变速器传来的转矩,并将动力合理地分配给左、右驱动轮,另外还承受作用于路面和车架或车身之间的垂直力力和横向力。驱动桥一般由主减速器、差速器、车轮传动装置和驱动桥壳等组成。 驱动桥作为汽车四大总成之一,它的性能的好坏直接影响整车性能,而对于载重汽车显得尤为重要。驱动桥设计应当满足如下基本要求: 1、符合现代汽车设计的一般理论。 2、外形尺寸要小,保证有必要的离地间隙。 3、合适的主减速比,以保证汽车的动力性和燃料经济性。 4、在各种转速和载荷下具有高的传动效率。 5、在保证足够的强度、刚度条件下,力求质量小,结构简单,加工工艺性 好,制造容易,拆装,调整方便。 6、与悬架导向机构运动协调,对于转向驱动桥,还应与转向机构运动协调。智能电子技术在汽车上得以推广使得汽车在安全行驶和其它功能更上一层楼。通过各种传感器实现自动驾驶。除些之外智能汽车装备有多种传感器能充分感知交通设施及环境的信息并能随时判断车辆及驾驶员是否处于危险之中,具备自主寻路、导航、避撞、不停车收费等功能。有效提高运输过程中的安全,减少驾驶员的操纵疲劳度,提高乘客的舒适度。当然蓄电池是电动汽车的关键,电动汽车用的蓄电池主要有:铅酸蓄电池、镍镉蓄电池、钠硫蓄电池、钠硫蓄电池、锂电池、锌—空气电池、飞轮电池、燃料电池和太阳能电池等。在诸多种电池中,燃料电池是迄今为止最有希望解决汽车能源短缺问题的动力源。燃料电池具有高效无污染的特性,不同于其他蓄电池,其不需要充电,只要外部不断地供给燃料,就能连续稳定地发电。燃料电池汽车(FCEV)具有可与内燃机汽车媲美的动力性能,在排放、燃油经济性方面明显优于内燃机车辆。

平面设计中英文对照外文翻译文献

(文档含英文原文和中文翻译) 中英文翻译 平面设计 任何时期平面设计可以参照一些艺术和专业学科侧重于视觉传达和介绍。采用多种方式相结合,创造和符号,图像和语句创建一个代表性的想法和信息。平面设计师可以使用印刷,视觉艺术和排版技术产生的最终结果。平面设计常常提到的进程,其中沟通是创造和产品设计。 共同使用的平面设计包括杂志,广告,产品包装和网页设计。例如,可能包括产品包装的标志或其他艺术作品,举办文字和纯粹的设计元素,如形状和颜色统一件。组成的一个最重要的特点,尤其是平面设计在使用前现有材料或不同的元素。 平面设计涵盖了人类历史上诸多领域,在此漫长的历史和在相对最近爆炸视觉传达中的第20和21世纪,人们有时是模糊的区别和重叠的广告艺术,平面设计和美术。毕竟,他们有着许多相同的内容,理论,原则,做法和语言,有时同样的客人或客户。广告艺术的最终目标是出售的商品和服务。在平面

设计,“其实质是使以信息,形成以思想,言论和感觉的经验”。 在唐朝( 618-906 )之间的第4和第7世纪的木块被切断打印纺织品和后重现佛典。阿藏印在868是已知最早的印刷书籍。 在19世纪后期欧洲,尤其是在英国,平面设计开始以独立的运动从美术中分离出来。蒙德里安称为父亲的图形设计。他是一个很好的艺术家,但是他在现代广告中利用现代电网系统在广告、印刷和网络布局网格。 于1849年,在大不列颠亨利科尔成为的主要力量之一在设计教育界,该国政府通告设计在杂志设计和制造的重要性。他组织了大型的展览作为庆祝现代工业技术和维多利亚式的设计。 从1892年至1896年威廉?莫里斯凯尔姆斯科特出版社出版的书籍的一些最重要的平面设计产品和工艺美术运动,并提出了一个非常赚钱的商机就是出版伟大文本论的图书并以高价出售给富人。莫里斯证明了市场的存在使平面设计在他们自己拥有的权利,并帮助开拓者从生产和美术分离设计。这历史相对论是,然而,重要的,因为它为第一次重大的反应对于十九世纪的陈旧的平面设计。莫里斯的工作,以及与其他私营新闻运动,直接影响新艺术风格和间接负责20世纪初非专业性平面设计的事态发展。 谁创造了最初的“平面设计”似乎存在争议。这被归因于英国的设计师和大学教授Richard Guyatt,但另一消息来源于20世纪初美国图书设计师William Addison Dwiggins。 伦敦地铁的标志设计是爱德华约翰斯顿于1916年设计的一个经典的现代而且使用了系统字体设计。 在20世纪20年代,苏联的建构主义应用于“智能生产”在不同领域的生产。个性化的运动艺术在俄罗斯大革命是没有价值的,从而走向以创造物体的功利为目的。他们设计的建筑、剧院集、海报、面料、服装、家具、徽标、菜单等。 Jan Tschichold 在他的1928年书中编纂了新的现代印刷原则,他后来否认他在这本书的法西斯主义哲学主张,但它仍然是非常有影响力。 Tschichold ,包豪斯印刷专家如赫伯特拜耳和拉斯洛莫霍伊一纳吉,和El Lissitzky 是平面设计之父都被我们今天所知。 他们首创的生产技术和文体设备,主要用于整个二十世纪。随后的几年看到平面设计在现代风格获得广泛的接受和应用。第二次世界大战结束后,美国经济的建立更需要平面设计,主要是广告和包装等。移居国外的德国包豪斯设计学院于1937年到芝加哥带来了“大规模生产”极简到美国;引发野火的“现代”建筑和设计。值得注意的名称世纪中叶现代设计包括阿德里安Frutiger ,设计师和Frutiger字体大学;保兰德,从20世纪30年代后期,直到他去世于1996年,采取的原则和适用包豪斯他们受欢迎的广告和标志设计,帮助创造一个独特的办法,美国的欧洲简约而成为一个主要的先驱。平面设计称为企业形象;约瑟夫米勒,罗克曼,设计的海报严重尚未获取1950年代和1960年代时代典型。 从道路标志到技术图表,从备忘录到参考手册,增强了平面设计的知识转让。可读性增强了文字的视觉效果。 设计还可以通过理念或有效的视觉传播帮助销售产品。将它应用到产品和公司识别系统的要素像标志、颜色和文字。连同这些被定义为品牌。品牌已日益成为重要的提供的服务范围,许多平面设计师,企业形象和条件往往是同时交替使用。

家用自动洗碗机的工作原理和使用说明

家用自动洗碗机工作原理和使用说明 洗碗这件事,看似不大却又在潜移默化的影响着我们的生活。当你刚和家人朋友吃完饭,谈笑风生的时候,转身看着一摞摞油腻的碗筷堆积在厨房的时候,笑会立刻僵住,内心os,“哎,又要洗碗了。。。。。”这可能是我们每个人都会经常遇到的事情,直白点说,洗碗就是件很讨厌的事情。 双手沾上油,手上那种滑滑的有点抓不住的感觉,再加上还有些残渣菜叶沾到手背上,还有七七八八的花椒粒胡椒粉辣椒籽,在油叽叽的手和碗盘之间生硬的硌着。努力的想把油腻的碗抓紧,却不得不接受花椒辣椒颗粒的硬拗,是的,我特别不喜欢这个感觉。而洗干净碗以后,哪怕已经把手清洗干净且抹上护手霜,洗碗液留下的那种涩涩的感觉总是在手上要停留很久,相当不舒服。 总之,这些种种,就能看出我是多么厌恶洗碗这件小事了,能躲多远就躲多远!!! 有了洗碗机之后,洗碗这件讨厌人的小事就不见啦。 那么洗碗机到底是中怎么工作(原理),以及如何操作? 【洗碗机的工作原理】 这款洗碗机是depelec中式洗碗机DCS-Q8,通过微电脑控制方式,用双层反向螺旋双峰喷臂,通过高压、高速喷射,形成立体循环水柱,水温可达70度高温,可以快速分解油脂,去除顽固动植物油脂,使细菌失去活力,在清洁剂的辅助作用下,对餐具进行冲洗,达到清洁效果。同时采用三重自清洗过滤系统,过滤细致,可以将污水残渣强力排除,使残渣不会停留在过滤器中,水压稳定、降低噪音,无泡洗碗更干净。高温清洗结束后,餐具表面温度逐渐降低过程中,不断蒸发水分,快速干燥餐具,如同置于暴晒中,让霉菌无所遁形。 【操作说明】 第一步:

按开/关键开启洗碗机,进入待机状态。 第二步: 按程序键,屏幕上的程序图标A组 会依次亮起, 选择适合你的洗涤程序。 第三步: 按下启动/哲停键,屏幕“:”闪烁、,洗涤程序开始。 亮时,进水异常提醒,确保水龙头已经打开。 亮时,表示需要添加亮碟剂,详见说明书添加量亮碟剂部分。 亮时,表示需要添加专用盐,详见说明书添加软水盐部分。 【使用好处】 1、洗涤:全封闭式洗涤,不用抹布,切断细菌传播途径。 2、消毒:采用加热及专门的洗涤用品:涤龙浸泡粉、消毒剂、洗洁精,足以杀死大肠杆菌、葡萄洗碗机球菌、肝炎病毒等病菌病毒。 3、烘干:洗刷后直接烘干,避免水渍留下的斑痕,使餐具更光洁。

汽车车辆类驱动桥的设计外文文献翻译、外文翻译、中英文翻译

附录I Drive axle powertrain at the end of their basic function is to increase the transmission came from the drive shaft or torque, and a reasonable distribution of power to the left and right wheel, in addition to acting on the road and under the frame or body legislation between the vertical, longitudinal and lateral force. General from the main drive axle reducer, differential, gear wheels and drive axle housings and other components. The design of the Drive axle: Drive axle should be designed to meet the basic requirements are as follows: 1. Select the main reduction ratio should be able to ensure the car has the best power and fuel economy. 2. Smaller size, to ensure that the necessary ground clearance. 3. Gear and other pieces of the work of a smooth transmission,and small noise. 4. In a variety of speed and load with a high transmission efficiency. 5. In ensuring adequate strength and stiffness conditions, should strive for the quality of small, especially under the mass-spring should be as small as possible in order to improve vehicle ride comfort. 6. And suspension movement-oriented coordination of steering drive axle, but also with the coordination of steering movement. 7. The structure of simple, good processing, manufacturing, easy disassembly, to facilitate adjustment. Drive axle classification -1-

英文文献及中文翻译

毕业设计说明书 英文文献及中文翻译 学院:专 2011年6月 电子与计算机科学技术软件工程

https://www.360docs.net/doc/c72499024.html, Overview https://www.360docs.net/doc/c72499024.html, is a unified Web development model that includes the services necessary for you to build enterprise-class Web applications with a minimum of https://www.360docs.net/doc/c72499024.html, is part of https://www.360docs.net/doc/c72499024.html, Framework,and when coding https://www.360docs.net/doc/c72499024.html, applications you have access to classes in https://www.360docs.net/doc/c72499024.html, Framework.You can code your applications in any language compatible with the common language runtime(CLR), including Microsoft Visual Basic and C#.These languages enable you to develop https://www.360docs.net/doc/c72499024.html, applications that benefit from the common language runtime,type safety, inheritance,and so on. If you want to try https://www.360docs.net/doc/c72499024.html,,you can install Visual Web Developer Express using the Microsoft Web Platform Installer,which is a free tool that makes it simple to download,install,and service components of the Microsoft Web Platform.These components include Visual Web Developer Express,Internet Information Services (IIS),SQL Server Express,and https://www.360docs.net/doc/c72499024.html, Framework.All of these are tools that you use to create https://www.360docs.net/doc/c72499024.html, Web applications.You can also use the Microsoft Web Platform Installer to install open-source https://www.360docs.net/doc/c72499024.html, and PHP Web applications. Visual Web Developer Visual Web Developer is a full-featured development environment for creating https://www.360docs.net/doc/c72499024.html, Web applications.Visual Web Developer provides an ideal environment in which to build Web sites and then publish them to a hosting https://www.360docs.net/doc/c72499024.html,ing the development tools in Visual Web Developer,you can develop https://www.360docs.net/doc/c72499024.html, Web pages on your own computer.Visual Web Developer includes a local Web server that provides all the features you need to test and debug https://www.360docs.net/doc/c72499024.html, Web pages,without requiring Internet Information Services(IIS)to be installed. Visual Web Developer provides an ideal environment in which to build Web sites and then publish them to a hosting https://www.360docs.net/doc/c72499024.html,ing the development tools in Visual Web Developer,you can develop https://www.360docs.net/doc/c72499024.html, Web pages on your own computer.

机械毕业设计英文外文翻译399驱动桥

附录A 英文文献 Drive Axle All vehicles have some type of drive axle/differential assembly incorporated into the driveline. Whether it is front, rear or four wheel drive, differentials are necessary for the smooth application of engine power to the road. Powerflow The drive axle must transmit power through a 90°angle. The flow of power in conventional front engine/rear wheel drive vehicles moves from the engine to the drive axle in approximately a straight line. However, at the drive axle, the power must be turned at right angles (from the line of the driveshaft) and directed to the drive wheels. This is accomplished by a pinion drive gear, which turns a circular ring gear. The ring gear is attached to a differential housing, containing a set of smaller gears that are splined to the inner end of each axle shaft. As the housing is rotated, the internal differential gears turn the axle shafts, which are also attached to the drive wheels. Rear-wheel drive Rear-wheel-drive vehicles are mostly trucks, very large sedans and many sports car and coupe models. The typical rear wheel drive vehicle uses a front mounted engine and transmission assemblies with a driveshaft coupling the transmission to the rear drive axle. Drive in through the layout of the bridge, the bridge drive shaft arranged vertically in the same vertical plane, and not the drive axle shaft, respectively, in their own sub-actuator with a direct connection, but the actuator is located at the front or the back of the adjacent shaft

中英文翻译与文献

Monolithic integrated circuit history The monolithic integrated circuit was born in the late-1970s, has experienced SCM, MCU, the SOC three big stages. SCM namely monolithic microcomputer (Single Chip Microcomputer) the stage, mainly seeks the best monolithic shape embedded system's best architecture. “the innovation pattern” obtains successfully, has established SCM and the general-purpose calculator completely different development path. In founds on the embedded system independent development path, Intel Corporation has lasting achievements. MCU namely micro controller (Micro Controller Unit) the stage, the main technological development direction is: Expands unceasingly when satisfies the embedded application, the object system request's each kind of peripheral circuit and the interface circuit, underline its object intellectualization control. It involves the domain is related with the object system, therefore, develops the MCU heavy responsibility to fall inevitably on electrical, the electronic technology factory. Looking from this angle, Intel fades out the MCU development also to have its objective factor gradually. Is developing the MCU aspect, the most famous factory family belongings count Philips Corporation. Philips Corporation by it in embedded application aspect huge superiority, MCS-51 from monolithic microcomputer rapidly expand to micro controller. Therefore, when we review the embedded system development path, do not forget Intel and the Philips historical merit. Monolithic integrated circuit is the embedded system's road of independent development, to the MCU stage development's important attribute, seeks application system's on chip maximized solution;

洗碗机原理

基本上,洗碗机就是一个清洗和冲刷脏碗碟的机器人。人类只需把碗碟放入洗碗机,添加洗涤剂,设定适当的洗碗周期,然后再开启洗碗机,洗碗机就会自动完成一整套的功能。一台洗碗机会: 给自己注水 把水加热到适当的温度 在适当的时候自动打开洗涤剂添加装置 通过喷头射出水来清洗碗碟 排出污水 往碗碟上喷洒更多的水进行冲刷 再次排出污水 如果使用者选择了烘干功能,它会自动加热 来烘干碗碟 除此之外,洗碗机会进行自我监测来确保各项功能都 运转正常。定时器(或小型计算机)控制每个运转过 程的持续时间。一个传感器监测着水和空气的温度, 以防洗碗机加热过度或损坏碗碟。另一个传感器监测 水位,一旦发现水位过高,它会启动排水功能来防止 水从洗碗机里溢出。有些洗碗机甚至还有传感器来监 测清洗碗碟之后水的肮脏程度,如果水足够干净,洗 碗机就知道碗碟都洗干净了。 本文将讨论洗碗机完成工作的整个过程,如何正确使用洗碗机以及在购买洗碗机时需要注意哪些方面的功能。 洗碗机内部 尽管洗碗机是不漏水的,但它里面并不会装满水,而只是把水灌注在底部的一个小盆中。在那里,加热装置把水温加热到约摄氏54度到60度。接着由一个泵把水推进到水喷头,水从那里被喷向脏碗碟。想象一下花园里没有喷嘴的水管,如果您用拇指按住水管的末端,减少水流出的空间,就会发现水会喷洒得非常强有力。洗碗机喷头的工作原理和它一样。水的冲击力还会使连接喷头的喷管旋转,就像草地喷灌器。 当清洗和冲刷结束后,水会重新排到那个小盆里,在那里泵会把水抽出洗碗机。根据洗碗机类型的不同,污水可能会直接流进水槽下面的管道,也有可能经过一段管道自己流进水槽。 洗涤运转过程的最后一步,即烘干,是可选择的。洗碗机底部的加热装置通过对内部的空气进行加热帮助碗碟变干。有些人为了节约能源就让碗碟在不加热的情况下自己变干。 洗碗机工作原理

驱动桥5000字外文翻译文献

As the bearing cage rotates, read the value 7. indicated on the scale. Preload normally is specified as torque re-8. quired to rotate the pinion bearing cage, so take a reading only when the cage is rotating. Starting torque will give a false reading. To calculate the preload torque, measure the 9. diameter of the bearing cage where the cord was wound. Divide this dimension in half to get the radius. 10. U se the following procedure to calculate the bearing preload torque:Standard. Pull (lb) 3 radius (inches) 5 preload (lb-in.)or Preload (lb-in.) 3 0.113 (a conversion constant) 5 preload (N .m) Install the yoke, flat washer, and nut. Tighten 6. the nut snugly. Tap the end of the input shaft lightly to seat the bearings. Measure the input shaft endplay again with 7. the dial indicator. If endplay is still incorrect, repeat steps 3 through 7. With the endplay correct, seal the shim pack 8. to prevent lube leakage. Then torque the i nput shaft nut and cover capscrews to the correct value. 24.5 A XLE ADJUSTMENTS AND CHECKS This section introduces the differential carrier adjust-ments, checks, and tests that the truck technician must be capable of performing; some have been r eferred to previously in the text. For the most part, the procedures described here are general in nature. The truck technician should refer to OEM service l iterature for specific procedures.PINION BEARING PRELOAD Most differential carriers are provided with a press-fit outer bearing on the drive pinion gear. Some older rear drive axles use an outer bearing, which slips over the drive pinion. The procedures for adjusting both types follow. Press-Fit Method Adjustment To adjust the pinion bearing preload using the press-fit method, use the following procedure: Assemble the pinion bearing cage, bearings, 1. spacer, and spacer washer (without drive pin-ion or oil seal). Center the bearing spacer and spacer washer between the two bearing cones (Figure 24–49). When a new gear set or pinion bearings are 2. used, select a nominal size spacer based on OEM specifications. If original parts are used, use a spacer removed during disassembly of the drive. Place the drive pinion and cage assembly in a 3. press, with the gear teeth toward the bottom.Apply and hold the press load to the pinion 4. bearing. As pressure is applied, rotate the bearing cage several times so that the bear-ings make normal contact. While pressure is held against the assembly, wind 5. a cord around the bearing cage several times.Attach a spring scale to the end of the cord 6. (Figure 24–50). Pull the cord with the scale on a horizontal line. FIGURE 24–49 Assembly of the pinion bearing cage. (Courtesy of Dana Corporation) FIGURE 24–50 Cage in press to check bearing p reload. Sleeve must apply

英文文献及中文翻译撰写格式

关于毕业设计说明书(论文)英文文献及中文翻译撰写格式 为提高我校毕业生毕业设计说明书(毕业论文)的撰写质量,做到毕业设计说明书(毕业论文)在内容和格式上的统一和规范,特规定如下: 一、装订顺序 论文(设计说明书)英文文献及中文翻译内容一般应由3个部分组成,严格按以下顺序装订。 1、封面 2、中文翻译 3、英文文献(原文) 二、书写格式要求 1、毕业设计(论文)英文文献及中文翻译分毕业设计说明书英文文献及中文翻译和毕业论文英文文献及中文翻译两种,所有出现相关字样之处请根据具体情况选择“毕业设计说明书” 或“毕业论文”字样。 2、毕业设计说明书(毕业论文)英文文献及中文翻译中的中文翻译用Word 软件编辑,英文文献用原文,一律打印在A4幅面白纸上,单面打印。 3、毕业设计说明书(毕业论文)英文文献及中文翻译的上边距:30mm;下边距:25mm;左边距:3Omm;右边距:2Omm;行间距1.5倍行距。 4、中文翻译页眉的文字为“中北大学2019届毕业设计说明书” 或“中北大学××××届毕业论文”,用小四号黑体字,页眉线的上边距为25mm;页脚的下边距为18mm。 5、中文翻译正文用小四号宋体,每章的大标题用小三号黑体,加粗,留出上下间距为:段前0.5行,段后0.5行;二级标题用小四号黑体,加粗;其余小标题用小四号黑体,不加粗。 6、文中的图、表、附注、公式一律采用阿拉伯数字分章编号。如图1.2,表2.3,附注3.2或式4.3。 7、图表应认真设计和绘制,不得徒手勾画。表格与插图中的文字一律用5号宋体。

每一插图和表格应有明确简短的图表名,图名置于图之下,表名置于表之上,图表号与图表名之间空一格。插图和表格应安排在正文中第一次提及该图表的文字的下方。当插图或表格不能安排在该页时,应安排在该页的下一页。 图表居中放置,表尽量采用三线表。每个表应尽量放在一页内,如有困难,要加“续表X.X”字样,并有标题栏。 图、表中若有附注时,附注各项的序号一律用阿拉伯数字加圆括号顺序排,如:注①。附注写在图、表的下方。 文中公式的编号用圆括号括起写在右边行末顶格,其间不加虚线。 8、文中所用的物理量和单位及符号一律采用国家标准,可参见国家标准《量和单位》(GB3100~3102-93)。 9、文中章节编号可参照《中华人民共和国国家标准文献著录总则》。

220V、380V 1200洗碗机

XYXWZ1型洗碗机 结构与安装操作简要介绍 注意: 本机必须由受过专业培训的合格技术人员安装,由受过专业培训的合格操作人员操作。安装及操作前请详细阅读本说明书。 1.型号与名称 型号:XYXWZ1 名称:罩式洗碗碟机 2.用途与特点 本机采用了目前最流行的旋转式洗涤臂和漂洗臂的设计,确保了一流的洗涤效果。电器上采用了电脑芯片程序控制系统和新颖的操作面板获得最舒适的操作过程,可以满足各类盘、碟、碗以及玻璃杯的高标准洗涤要求。特别适用于宾馆、饭店、餐厅和食堂等卫生洗涤餐具的场所。本产品还具有以下特点: 2.1不锈钢结构的双层上罩盖,前置式操作杆,操作舒适并节约能源。后敞开式的罩 壳,打开机罩使蒸汽从后面溢出,从而增强了操作的舒适度。420mm的净通高度,洗涤大碗碟更为方便。 2.2圆弧角过渡的不锈钢洗涤水槽美观,无腐蚀,易操作,易清洗。本机具有自清洗 功能,清洗极为方便,最大程度保持机器的清洁与卫生。本机结构简洁、牢固,机器性能可靠,易维修,寿命长。 2.3微电脑系统控制,三档的洗涤时间,客户可根据餐具的污垢程度自行选择,使洗 涤的效果更佳,操作更简便。

3.技术参数 洗涤篮规格500×500mm 动作时间60/90/120秒 生产能力17~60篮/小时 电源380V、50HZ / 60HZ 三相五线 ( 220V、50HZ / 60HZ 三相四线) 水泵功率0.9Kw 水槽加热器功率 3.0Kw 漂洗加热器功率12Kw 水槽容量24L 漂洗用水量3L/篮 外形尺寸705×850×1490mm 净重150Kg 4. 主要结构及工作原理 本机主要由机架、清洗系统、漂洗系统及电器控制等部分组成。通过不锈钢水泵将水从水槽抽出加压并循环使用,水槽内的水温由温控器控制在55℃左右(50~60℃)。本机以洗涤和漂洗循环方式动作。在洗涤过程中洗涤篮固定不动,上下洗涤臂由洗涤水推动旋转。此方式的优点在于洗涤臂可从各个角度对碗、碟进行清洗,不存在死角,保证了洗涤质量。洗涤水槽中需要加入专用洗涤剂,洗涤剂的主要作用是除去碗碟上的油腻及残渣,并使这些油腻和残渣悬浮在洗涤水槽中,再通过漂洗进水溢流到外部,有效的减少洗涤过程中油污堆积。主洗完毕后是漂洗程序,漂洗臂喷出82℃(80~85℃)的高温净水(洗杯时温度控制为65℃),上一个程序的漂洗水作为下一次洗涤水用,从而保证了洗涤水的清洁性,也节约了用水。漂洗时,用分配器自动加入催干剂,能迅速挥发餐具表面水分,不留痕迹,促进餐具清洁干燥。 5. 安装与调整 5.1检查:检查机器各部件连接是否牢靠,紧固一遍所有螺丝 5.2 调平:调整机器的四脚将机器调平,用水平测试仪检测,做水平和垂直两个方向 的校准,使机器安放平稳。(海拔高度不超过2500m) 5.3电源连接:电源为三相380V时,进线为三根火线、一根零线、一根地线,线径为