机械设计英文参考文献

MOLD MATERIALS MAKING THE MOST OF HIGH—PERFORMANCE

MOLD MATERIALS

Understanding high conductivity alloys and optimizing their use can help you build better molds.

By Douglas Veitch, Director, Brush Wellman

Injection molders and blow molders can benefit from high conductivity alloys by achieving faster cycle times and better part quality. There are certain properties of the mold material and polymer that enable these efficiencies to be realized. Once these characteristics are understood, mold builders can optimize their use of high-performance materials to provide a durable, fast-cycling mold for their customers.

Cooling Time

Mold Alloy Thermal Properties

Some characteristics of mold materials enable us to better understand the thermal process that occurs while molding. Three important properties are:

1. Thermal Conductivity

Higher thermal conductivity equates to the transfer of more thermal energy per unit of time under steady state conditions.

2. Thermal Diffusivity

Higher thermal diffusivity means that thermal equilibrium will be reached faster when the temperature changes. A good thermal diffuser will react more quickly to environmental temperature changes.

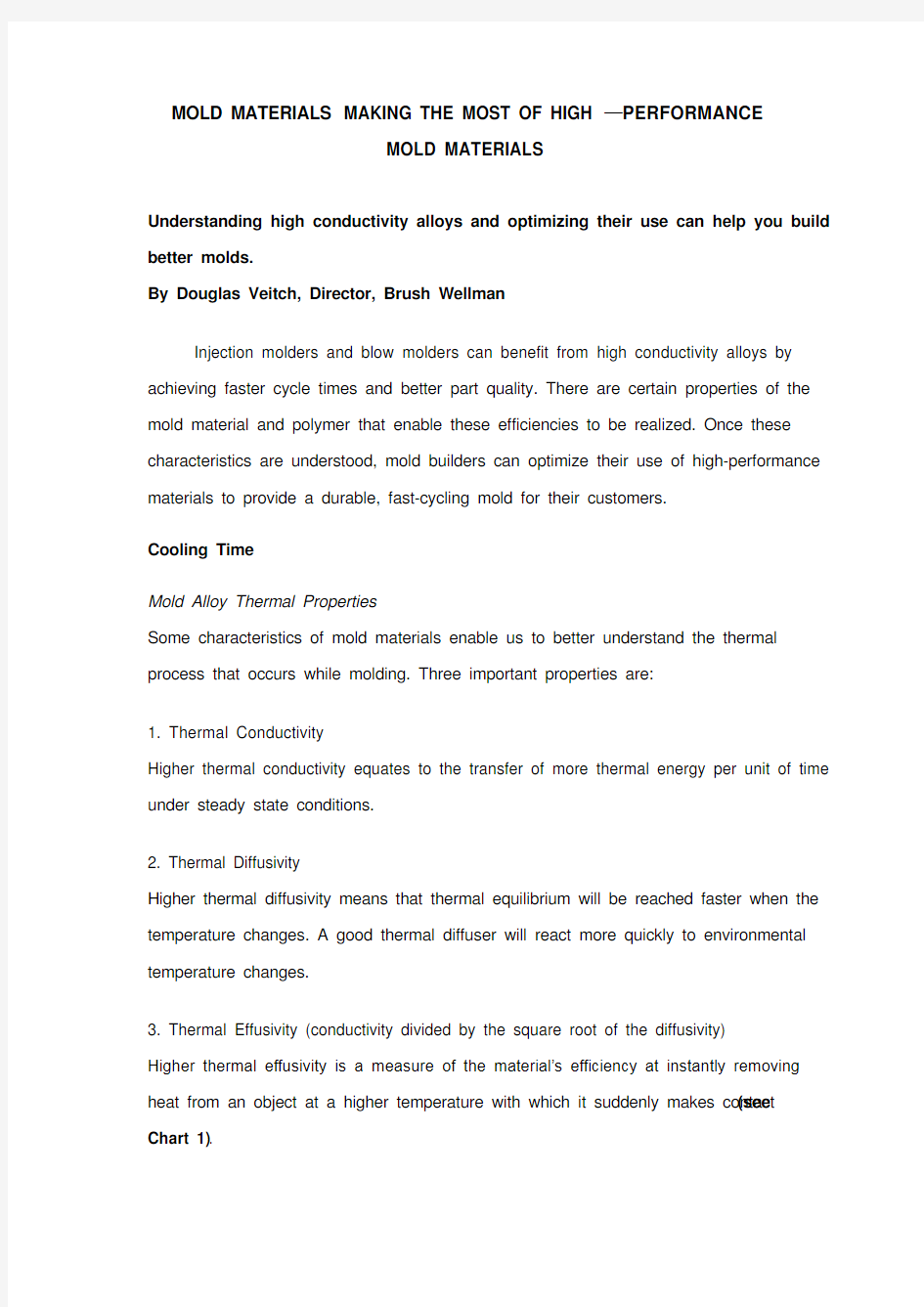

3. Thermal Effusivity (conductivity divided by the square root of the diffusivity)

Higher thermal effusivity is a measure of the material’s efficiency at instantly removing heat from an object at a higher temperature with which it suddenly makes contact (see Chart 1).

The following explains what all of this means when molding plastics.

1. Heat mold up to operating temperature (via water channels).

?The higher diffusivity allows the copper mold alloy to reach equilibrium faster, so the molding operation can begin sooner.

2. Inject hot plastic melt into the mold and cool.

?Higher effusivity means the mold will begin to instantly and efficiently remove heat from the plastic.

?Then the high diffusivity translates to reaching steady state, uniform temperature quickly.

?Finally, once at equilibrium the conductivity determines how fast the thermal energy will be removed from the plastic until the part reaches the desired ejection temperature.

3. Maintain setpoint temperature (equal to water temperature) during mold-open, ejection and mold-close portions of the cycle.

?Again, the high diffusivity enables the mold to maintain equilibrium at setpoint during mold open, ejection and mold close. Since the air is a poor thermal medium, the contact between the water and copper is the overriding factor.

Figure 1: IR temp distribution. Images courtesy of Brush Wellman Inc.

Figure 1 shows pictures from a thermal FEA illustrating the uniform temperature of a copper beryllium mold compared to that of a mold made of P-20 steel.

Polymer Types

The two main polymer families—semi-crystalline and amorphous—both benefit from higher conductivity mold materials.

Semi-crystalline polymers have a densely packed, uniform molecular structure and include materials such as polyamide (nylon), polyethylene, polypropylene and polyacetal. These polymers become amorphous when melted during processing and will become semi-crystalline again when cooled.

Amorphous polymers have a loose and random molecular structure, so that in some cases amorphous materials are transparent. Both types of polymers can benefit from improved heat transfer and reduced cooling time.

The following are some differences that need to be realized to provide a better understanding of the application.

?Crystalline materials have a sharp melting point, and thus a latent heat energy that must be added when melting, and removed when cooling. The plastic needs to be solidified and cooled below the heat deflection temperature before ejection from the mold. The heat deflection temperature (HDT) is available on most resin datasheets. Just getting below the melting point is not enough. The part has to be cooled to the point where it is stiff enough to eject. Glass and mineral fillers increase the crystallization rate and the HDT so the part can be ejected at a higher temperature without deformation.

?Amorphous polymers do not have a melting point, but as the heat input is increased above the glass transition temperature (Tg), the viscosity of the polymer decreases until it begins to flow. Heat is added until the plastic can flow adequately to fill the mold. Then the heat has to be removed until the polymer is below the Tg—in many cases before the part will be stiff enough to be ejected.

In general, crystalline polymers contain more heat energy due to the latent heat. For example polycarbonate—which is amorphous—has a heat capacity of 1.2 J/(g oK) while polypropylene—which is semi-crystalline—has a heat capacity of 1.9 J/(g oK) or 58 percent higher. Molders will experience cycle time reductions and improved uniformity of cooling for both families of plastics when using high conductivity mold alloys.

Some semi-crystalline materials—such as nylon—require relatively high mold temperatures to provide good surface finish and maximum crystallinity. High conductivity mold alloys can improve both characteristics, and reduce cycle time as an added bonus.

This effect is achieved by simply running the mold at the desired temperature—for example 180oF. The high conductivity alloy will be able to remove heat faster than steel, but at the recommended temperature, and the heat removal will be more uniform. The result is reduced cooling time and more uniform crystallinity in the molded part. When molding amorphous plastics, uniform cooling also is very important. For clear polymers—like polycarbonate—the part will have better clarity and toughness.

Water Cooling

With steel tools, molders often run chillers to reduce cycle times and to compensate for the reduced heat transfer of the steel. The cold tool will often result in condensation on the mold surface that can adversely affect part quality. With high-conductivity tool alloys, the cooling water can be set at a higher temperature to prevent condensation, and yet achieve much faster cycles than steel tools. Also, the surface temperature of the mold will be very close to the water temperature setpoint. The long-term heat transfer performance of copper alloys is very good, because copper resists corrosion and bio-fouling in the cooling channels.

Economics

Cycle time reduction always has been a key effort for molders. Increasingly, molders are attempting to improve cycles to offset higher resin, energy and transportation costs that they have not been able to pass through to their customers. Using copper mold alloys allows molders to improve their production rate, avoid capital investment and minimize quality issues.

Higher conductivity molds provide more uniform cooling than steel tools, resulting in better dimensional control, decreased warpage and part strength improvements. Payback analysis for molds using high-performance alloys yields very desirable numbers due to the reduced cooling times.

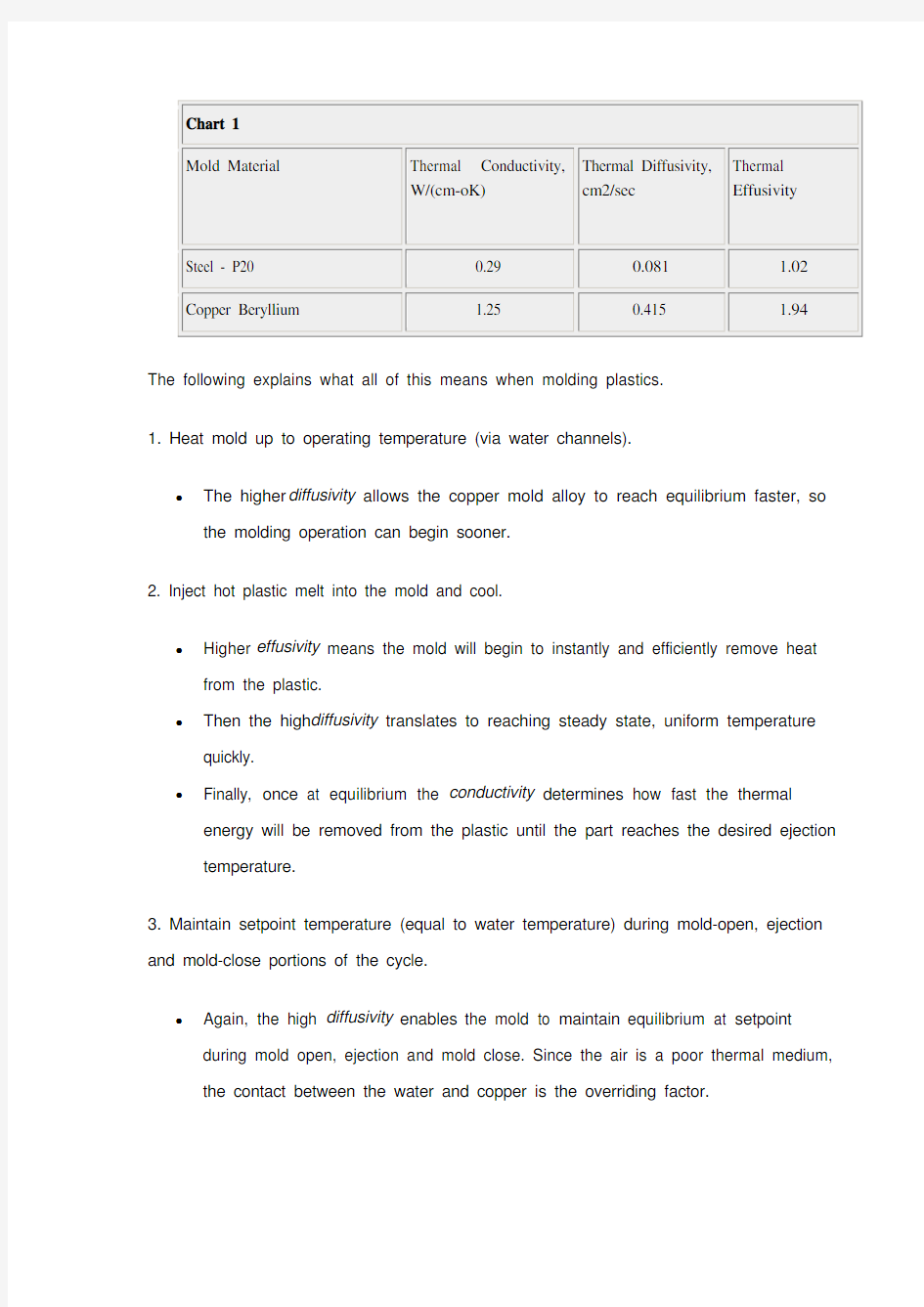

Figure 2: Copper beryllium insert stands up well to the glass-filled nylon used in chair bases.

Applications

1. Recently, in the case of a large polyethylene lid, the molder calculated the

payback at 10 days using a copper beryllium insert in a steel tool. The cycle time was reduced from 75 seconds to 52 seconds, and allowed the molder to avoid purchasing an additional molding machine to keep up with demand. Capital avoidance is sometimes overlooked, but can be of tremendous benefit in the long term.

2. Another example is a chair base made of glass-reinforced nylon. The

manufacturer was able to obtain a 20 percent cycle time reduction using copper beryllium for a core insert in the chair base mold (see Figure 2). Prior to using copper beryllium, the manufacturer was using strictly steel in its molds. After switching to molds using copper beryllium inserts they have witnessed a decrease in cycle from 122 seconds to 98 seconds—allowing for faster production throughout. Also, the dimensional control of the hub diameter was improved.

By using copper beryllium, the manufacturer was able to increase annual production by 500,000 chair bases without purchasing additional injection molding machines. With all steel tools, four additional presses were required to meet the growing demand Again, major capital outlay was avoided for a minimal investment in high conductivity mold alloys.

Conclusion

The benefits of high conductivity alloys include (1) faster cycle times, (2) uniform mold temperature, (3) better part quality, (4) low-maintenance cooling channels, (5) and suitability for amorphous and crystalline polymer families. Mold builders that have expertise and capabilities with these mold alloys have a competitive edge in a global marketplace. Such moldmakers can offer their customers high-performance molds that will enable their customers to be more competitive and profitable. And we all know that profitable customers are the best kind.

毕业设计外文翻译附原文

外文翻译 专业机械设计制造及其自动化学生姓名刘链柱 班级机制111 学号1110101102 指导教师葛友华

外文资料名称: Design and performance evaluation of vacuum cleaners using cyclone technology 外文资料出处:Korean J. Chem. Eng., 23(6), (用外文写) 925-930 (2006) 附件: 1.外文资料翻译译文 2.外文原文

应用旋风技术真空吸尘器的设计和性能介绍 吉尔泰金,洪城铱昌,宰瑾李, 刘链柱译 摘要:旋风型分离器技术用于真空吸尘器 - 轴向进流旋风和切向进气道流旋风有效地收集粉尘和降低压力降已被实验研究。优化设计等因素作为集尘效率,压降,并切成尺寸被粒度对应于分级收集的50%的效率进行了研究。颗粒切成大小降低入口面积,体直径,减小涡取景器直径的旋风。切向入口的双流量气旋具有良好的性能考虑的350毫米汞柱的低压降和为1.5μm的质量中位直径在1米3的流量的截止尺寸。一使用切向入口的双流量旋风吸尘器示出了势是一种有效的方法,用于收集在家庭中产生的粉尘。 摘要及关键词:吸尘器; 粉尘; 旋风分离器 引言 我们这个时代的很大一部分都花在了房子,工作场所,或其他建筑,因此,室内空间应该是既舒适情绪和卫生。但室内空气中含有超过室外空气因气密性的二次污染物,毒物,食品气味。这是通过使用产生在建筑中的新材料和设备。真空吸尘器为代表的家电去除有害物质从地板到地毯所用的商用真空吸尘器房子由纸过滤,预过滤器和排气过滤器通过洁净的空气排放到大气中。虽然真空吸尘器是方便在使用中,吸入压力下降说唱空转成比例地清洗的时间,以及纸过滤器也应定期更换,由于压力下降,气味和细菌通过纸过滤器内的残留粉尘。 图1示出了大气气溶胶的粒度分布通常是双峰形,在粗颗粒(>2.0微米)模式为主要的外部来源,如风吹尘,海盐喷雾,火山,从工厂直接排放和车辆废气排放,以及那些在细颗粒模式包括燃烧或光化学反应。表1显示模式,典型的大气航空的直径和质量浓度溶胶被许多研究者测量。精细模式在0.18?0.36 在5.7到25微米尺寸范围微米尺寸范围。质量浓度为2?205微克,可直接在大气气溶胶和 3.85至36.3μg/m3柴油气溶胶。

机械设计设计外文文献翻译、中英文翻译、外文翻译

机械设计 摘要:机器是由机械装置和其它组件组成的。它是一种用来转换或传递能量的装置,例如:发动机、涡轮机、车辆、起重机、印刷机、洗衣机、照相机和摄影机等。许多原则和设计方法不但适用于机器的设计,也适用于非机器的设计。术语中的“机械装置设计”的含义要比“机械设计”的含义更为广泛一些,机械装置设计包括机械设计。在分析运动及设计结构时,要把产品外型以及以后的保养也要考虑在机械设计中。在机械工程领域中,以及其它工程领域中,所有这些都需要机械设备,比如:开关、凸轮、阀门、船舶以及搅拌机等。 关键词:设计流程设计规则机械设计 设计流程 设计开始之前就要想到机器的实际性,现存的机器需要在耐用性、效率、重量、速度,或者成本上得到改善。新的机器必需具有以前机器所能执行的功能。 在设计的初始阶段,应该允许设计人员充分发挥创造性,不要受到任何约束。即使产生了许多不切实际的想法,也会在设计的早期,即在绘制图纸之前被改正掉。只有这样,才不致于阻断创新的思路。通常,还要提出几套设计方案,然后加以比较。很有可能在这个计划最后决定中,使用了某些不在计划之内的一些设想。 一般的当外型特点和组件部分的尺寸特点分析得透彻时,就可以全面的设计和分析。接着还要客观的分析机器性能的优越性,以及它的安全、重量、耐用性,并且竞争力的成本也要考虑在分析结果之内。每一个至关重要的部分要优化它的比例和尺寸,同时也要保持与其它组成部分相协调。 也要选择原材料和处理原材料的方法。通过力学原理来分析和实现这些重要的特性,如那些静态反应的能量和摩擦力的最佳利用,像动力惯性、加速动力和能量;包括弹性材料的强度、应力和刚度等材料的物理特性,以及流体润滑和驱动器的流体力学。设计的过程是重复和合作的过程,无论是正式或非正式的进行,对设计者来说每个阶段都很重要。 最后,以图样为设计的标准,并建立将来的模型。如果它的测试是符合事先要

毕业设计英文翻译

使用高级分析法的钢框架创新设计 1.导言 在美国,钢结构设计方法包括允许应力设计法(ASD),塑性设计法(PD)和荷载阻力系数设计法(LRFD)。在允许应力设计中,应力计算基于一阶弹性分析,而几何非线性影响则隐含在细部设计方程中。在塑性设计中,结构分析中使用的是一阶塑性铰分析。塑性设计使整个结构体系的弹性力重新分配。尽管几何非线性和逐步高产效应并不在塑性设计之中,但它们近似细部设计方程。在荷载和阻力系数设计中,含放大系数的一阶弹性分析或单纯的二阶弹性分析被用于几何非线性分析,而梁柱的极限强度隐藏在互动设计方程。所有三个设计方法需要独立进行检查,包括系数K计算。在下面,对荷载抗力系数设计法的特点进行了简要介绍。 结构系统内的内力及稳定性和它的构件是相关的,但目前美国钢结构协会(AISC)的荷载抗力系数规范把这种分开来处理的。在目前的实际应用中,结构体系和它构件的相互影响反映在有效长度这一因素上。这一点在社会科学研究技术备忘录第五录摘录中有描述。 尽管结构最大内力和构件最大内力是相互依存的(但不一定共存),应当承认,严格考虑这种相互依存关系,很多结构是不实际的。与此同时,众所周知当遇到复杂框架设计中试图在柱设计时自动弥补整个结构的不稳定(例如通过调整柱的有效长度)是很困难的。因此,社会科学研究委员会建议在实际设计中,这两方面应单独考虑单独构件的稳定性和结构的基础及结构整体稳定性。图28.1就是这种方法的间接分析和设计方法。

在目前的美国钢结构协会荷载抗力系数规范中,分析结构体系的方法是一阶弹性分析或二阶弹性分析。在使用一阶弹性分析时,考虑到二阶效果,一阶力矩都是由B1,B2系数放大。在规范中,所有细部都是从结构体系中独立出来,他们通过细部内力曲线和规范给出的那些隐含二阶效应,非弹性,残余应力和挠度的相互作用设计的。理论解答和实验性数据的拟合曲线得到了柱曲线和梁曲线,同时Kanchanalai发现的所谓“精确”塑性区解决方案的拟合曲线确定了梁柱相互作用方程。 为了证明单个细部内力对整个结构体系的影响,使用了有效长度系数,如图28.2所示。有效长度方法为框架结构提供了一个良好的设计。然而,有效长度方法的

机械手机械设计论文中英文资料对照外文翻译

中英文资料对照外文翻译 机械设计 摘要: 机器由机械和其他元件组成的用来转换和传输能量的装置。比如:发动机、涡轮机、车、起重机、印刷机、洗衣机和摄影机。许多机械方面设计的原则和方法也同样适用于非机械方面。术语中的“构造设计”的含义比“机械设计”更加广泛,构造设计包括机械设计。在进行运动分析和结构设计时要把产品的维护和外形也考虑在机械设计中。在机械工程领域中,以及其它工程领域,都需要机械设备,比如:开关、凸轮、阀门、船舶以及搅拌机等。 关键词:设计流程设计规则机械设计 设计流程 设计开始之前就要想到机器的实用性,现有的机器需要在耐用性、效率、重量、速度,或者成本上得到改善。新的机器必需能够完全或部分代替以前人的功能,比如计算、装配、维修。 在设计的初级阶段,应该充分发挥设计人员的创意,不要受到任何约束。即使有一些不切实际的想法,也可以在设计的早期,即在绘制图纸之前被改正掉。只有这样,才不致于阻断创新的思路。通常,必须提出几套设计方案,然后进行比较。很有可能在这个计划最后指定使用某些不在计划方案内的一些想法的计划。 一般当产品的外型和组件的尺寸特点已经显现出来的时候,就可以进行全面的设计和分析。接着还要客观的分析机器性能、安全、重量、耐用性,并且成本也要考虑在内。每一个至关重要的部分要优化它的比例和尺寸,同时也要保持与其它组成部分的平衡。 选择原材料和工艺的方法。通过力学原理来分析和实现这些重要的特性,如稳定和反应的能量和摩擦力的利用,动力惯性、加速度、能量;包括材料的弹性强度、应力和刚度等物理特性,以及流体的润滑和驱动器的流体力学。设计的过程是一个反复与合作的过程,无论是正式的还是非正式的,对设计者来说每个阶段都很重要。。产品设计需要大量的研究和提升。许多的想法,必须通过努力去研究成为一种理念,然后去使用或放弃。

毕业设计_英语专业论文外文翻译

1. Introduction America is one of the countries that speak English. Because of the special North American culture, developing history and the social environment, American English has formed its certain unique forms and the meaning. Then it turned into American English that has the special features of the United States. American English which sometimes also called United English or U.S English is the form of the English language that used widely in the United States .As the rapid development of American economy, and its steady position and strong power in the world, American English has become more and more widely used. As in 2005, more than two-thirds of English native speakers use various forms of American English. The philologists of the United States had divided the English of the United States into four major types: “America n creating”; “Old words given the new meaning”; “Words that eliminated by English”;“The phonetic foreign phrases and the languages that are not from the English immigrates”[1]. Compared to the other languages, American English is much simple on word spelling, usage and grammar, and it is one of the reasons that American English is so popular in the world. The thesis analyzes the differences between American English and British English. With the main part, it deals with the development of American English, its peculiarities compared to that of British English, its causes and tendency. 2. Analyses the Differences As we English learners, when we learning English in our junior or senior school, we already came across some words that have different spellings, different pronunciations or different expressions, which can be represented by following contrasted words: spellings in "color" vs. "colour"; pronunciations in "sec-re-ta-ry" vs. "sec-re-try";

机械设计外文翻译(中英文)

机械设计理论 机械设计是一门通过设计新产品或者改进老产品来满足人类需求的应用技术科学。它涉及工程技术的各个领域,主要研究产品的尺寸、形状和详细结构的基本构思,还要研究产品在制造、销售和使用等方面的问题。 进行各种机械设计工作的人员通常被称为设计人员或者机械设计工程师。机械设计是一项创造性的工作。设计工程师不仅在工作上要有创造性,还必须在机械制图、运动学、工程材料、材料力学和机械制造工艺学等方面具有深厚的基础知识。如前所诉,机械设计的目的是生产能够满足人类需求的产品。发明、发现和科技知识本身并不一定能给人类带来好处,只有当它们被应用在产品上才能产生效益。因而,应该认识到在一个特定的产品进行设计之前,必须先确定人们是否需要这种产品。 应当把机械设计看成是机械设计人员运用创造性的才能进行产品设计、系统分析和制定产品的制造工艺学的一个良机。掌握工程基础知识要比熟记一些数据和公式更为重要。仅仅使用数据和公式是不足以在一个好的设计中做出所需的全部决定的。另一方面,应该认真精确的进行所有运算。例如,即使将一个小数点的位置放错,也会使正确的设计变成错误的。 一个好的设计人员应该勇于提出新的想法,而且愿意承担一定的风险,当新的方法不适用时,就使用原来的方法。因此,设计人员必须要有耐心,因为所花费的时间和努力并不能保证带来成功。一个全新的设计,要求屏弃许多陈旧的,为人们所熟知的方法。由于许多人墨守成规,这样做并不是一件容易的事。一位机械设计师应该不断地探索改进现有的产品的方法,在此过程中应该认真选择原有的、经过验证的设计原理,将其与未经过验证的新观念结合起来。 新设计本身会有许多缺陷和未能预料的问题发生,只有当这些缺陷和问题被解决之后,才能体现出新产品的优越性。因此,一个性能优越的产品诞生的同时,也伴随着较高的风险。应该强调的是,如果设计本身不要求采用全新的方法,就没有必要仅仅为了变革的目的而采用新方法。 在设计的初始阶段,应该允许设计人员充分发挥创造性,不受各种约束。即使产生了许多不切实际的想法,也会在设计的早期,即绘制图纸之前被改正掉。只有这样,才不致于堵塞创新的思路。通常,要提出几套设计方案,然后加以比较。很有可能在最后选定的方案中,采用了某些未被接受的方案中的一些想法。

java毕业论文外文文献翻译

Advantages of Managed Code Microsoft intermediate language shares with Java byte code the idea that it is a low-level language witha simple syntax , which can be very quickly translated intonative machine code. Having this well-defined universal syntax for code has significant advantages. Platform independence First, it means that the same file containing byte code instructions can be placed on any platform; atruntime the final stage of compilation can then be easily accomplished so that the code will run on thatparticular platform. In other words, by compiling to IL we obtain platform independence for .NET, inmuch the same way as compiling to Java byte code gives Java platform independence. Performance improvement IL is actually a bit more ambitious than Java bytecode. IL is always Just-In-Time compiled (known as JIT), whereas Java byte code was ofteninterpreted. One of the disadvantages of Java was that, on execution, the process of translating from Javabyte code to native executable resulted in a loss of performance. Instead of compiling the entire application in one go (which could lead to a slow start-up time), the JITcompiler simply compiles each portion of code as it is called (just-in-time). When code has been compiled.once, the resultant native executable is stored until the application exits, so that it does not need to berecompiled the next time that portion of code is run. Microsoft argues that this process is more efficientthan compiling the entire application code at the start, because of the likelihood that large portions of anyapplication code will not actually be executed in any given run. Using the JIT compiler, such code willnever be compiled.

毕业设计外文翻译格式实例.

理工学院毕业设计(论文)外文资料翻译 专业:热能与动力工程 姓名:赵海潮 学号:09L0504133 外文出处:Applied Acoustics, 2010(71):701~707 附件: 1.外文资料翻译译文;2.外文原文。

附件1:外文资料翻译译文 基于一维CFD模型下汽车排气消声器的实验研究与预测Takeshi Yasuda, Chaoqun Wua, Noritoshi Nakagawa, Kazuteru Nagamura 摘要目前,利用实验和数值分析法对商用汽车消声器在宽开口喉部加速状态下的排气噪声进行了研究。在加热工况下发动机转速从1000转/分钟加速到6000转/分钟需要30秒。假定其排气消声器的瞬时声学特性符合一维计算流体力学模型。为了验证模拟仿真的结果,我们在符合日本工业标准(JIS D 1616)的消声室内测量了排气消声器的瞬态声学特性,结果发现在二阶发动机转速频率下仿真结果和实验结果非常吻合。但在发动机高阶转速下(从5000到6000转每分钟的四阶转速,从4200到6000转每分钟的六阶转速这样的高转速范围内),计算结果和实验结果出现了较大差异。根据结果分析,差异的产生是由于在模拟仿真中忽略了流动噪声的影响。为了满足市场需求,研究者在一维计算流体力学模型的基础上提出了一个具有可靠准确度的简化模型,相对标准化模型而言该模型能节省超过90%的执行时间。 关键字消声器排气噪声优化设计瞬态声学性能 1 引言 汽车排气消声器广泛用于减小汽车发动机及汽车其他主要部位产生的噪声。一般而言,消声器的设计应该满足以下两个条件:(1)能够衰减高频噪声,这是消声器的最基本要求。排气消声器应该有特定的消声频率范围,尤其是低频率范围,因为我们都知道大部分的噪声被限制在发动机的转动频率和它的前几阶范围内。(2)最小背压,背压代表施加在发动机排气消声器上额外的静压力。最小背压应该保持在最低限度内,因为大的背压会降低容积效率和提高耗油量。对消声器而言,这两个重要的设计要求往往是互相冲突的。对于给定的消声器,利用实验的方法,根据距离尾管500毫米且与尾管轴向成45°处声压等级相近的排气噪声来评估其噪声衰减性能,利用压力传感器可以很容易地检测背压。 近几十年来,在预测排气噪声方面广泛应用的方法有:传递矩阵法、有限元法、边界元法和计算流体力学法。其中最常用的方法是传递矩阵法(也叫四端网络法)。该方

(机械设计理论)中英文对照 Machine design theory

机械设计理论 The machine design theory The machine design is through designs the new product or improves the old product to meet the human need the application technical science. It involves the project technology each domain, mainly studies the product the size, the shape and the detailed structure basic idea, but also must study the product the personnel which in aspect the and so on manufacture, sale and use question. Carries on each kind of machine design work to be usually called designs the personnel or machine design engineer. The machine design is a creative work. Project engineer not only must have the creativity in the work, but also must in aspect and so on mechanical drawing, kinematics, engineerig material, materials mechanics and machine manufacture technology has the deep elementary knowledge. If front sues, the machine design goal is the production can meet the human need the product. The invention, the discovery and technical knowledge itself certainly not necessarily can bring the advantage to the humanity, only has when they are applied can produce on the product the benefit. Thus, should realize to carries on before the design in a specific product, must first determine whether the people do need this kind of product Must regard as the machine design is the machine design personnel carries on using creative ability the product design, the system analysis and a formulation product manufacture technology good opportunity. Grasps the project elementary knowledge to have to memorize some data and the formula is more important than. The merely service data and the formula is insufficient to the completely decision which makes in a good design needs. On the other hand, should be earnest precisely carries on all operations. For example, even if places wrong a decimal point position, also can cause the correct design to turn wrongly.

本科毕业设计外文文献翻译

( 本科毕业设计外文文献翻译 学校代码: 10128 学 号: 题 目:Shear wall structural design of high-level framework 学生姓名: 学 院:土木工程学院 系 别:建筑工程系 专 业:土木工程专业(建筑工程方向) 班 级:土木08-(5)班 指导教师: (副教授)

Shear wall structural design of high-level framework Wu Jicheng Abstract: In this paper the basic concepts of manpower from the frame shear wall structure, analysis of the structural design of the content of the frame shear wall, including the seismic wall shear span ratio design, and a concrete structure in the most commonly used frame shear wall structure the design of points to note. Keywords: concrete; frame shear wall structure; high-rise buildings The wall is a modern high-rise buildings is an important building content, the size of the frame shear wall must comply with building regulations. The principle is that the larger size but the thickness must be smaller geometric features should be presented to the plate, the force is close to cylindrical. The wall shear wall structure is a flat component. Its exposure to the force along the plane level of the role of shear and moment, must also take into account the vertical pressure. Operate under the combined action of bending moments and axial force and shear force by the cantilever deep beam under the action of the force level to look into the bottom mounted on the basis of. Shear wall is divided into a whole wall and the associated shear wall in the actual project, a whole wall for example, such as general housing construction in the gable or fish bone structure film walls and small openings wall. Coupled Shear walls are connected by the coupling beam shear wall. But because the

毕业设计英文翻译资料(中文)

故障概率模型的数控车床 摘要:领域的失效分析被计算机数字化控制(CNC)车床描述。现场收集了为期两年的约80台数控车床的故障数据。编码系统代码失效数据是制定和失效分析数据库成立的数控车床。失败的位置和子系统,失效模式及原因进行了分析,以显示薄弱子系统的数控车床。另外,故障的概率模型,分析了数控车床的模糊多准则综合评价。 作者关键词:数控车床;场失败;概率模型;模糊信息 文章概述 1.介绍 2. CNC车床的概述 3.收集和整理数据 3.1. 收集数据 3.2. 领域失效数据的有效性 3.3. 数据核对和数据库 4. 失效分析 4.1. 对失败位置和子系统的频率分析 4.2. 对失败形式的频率分析 5.失败机率模型 5.1. 方法学 5.2. 分布倍之间连续的失败 5.3. 修理时间的发行 6.结论 1.介绍 在过去十年中,计算机数字化控制(CNC)车床已经越来越多地被引入到机械加工过程中。由于其固有的灵活性很大,稳定的加工精度和高生产率,数控车床是能给用户巨大的利益。然而,作为一个单一的数控车床故障也许会导致整个生产车间被停止,而且维修更加困难和昂贵,当故障发生时[1],数控车床能够给用户带来很多的麻烦。 与此同时,制造商还需要持续改进数控车床的可靠性来提高市场的竞争力。因此,数控车床的可靠性能使生产商和用户增加显著性和至关重要的意义。 需要改进数控车床的可靠性,使用户和制造商收集和分析领域的故障数据和采取措施减少停机时间。本文论述了研究失效模式及原因,失效的位置和薄弱的子系统,故障概率模型的数控车床。

图1 系统框图的数控车床 机械系统包括主轴及其传动链(固定在主轴箱),两根滑动轴(命名X、Z或者U,W在轮),车床拖板箱,转动架或刀架,尾座,床身等。主轴持续或加强连续变速,驱动交流或直流主轴电机直接或通过主传动,并有一个光电编码器的主轴车削螺纹。X和Z 两根轴的驱动交流或直流伺服车削螺纹和控制同时进行。该转动架或刀架可自动交换工

机械设计理论英文翻译

译文 机械设计理论 机械设计是一门通过设计新产品或者改进老产品来满足人类需求的应用技术科学。它涉及工程技术的各个领域,主要研究产品的尺寸、形状和详细结构的基本构思,还要研究产品在制造、销售和使用等方面的问题。 进行各种机械设计工作的人员通常被称为设计人员或者机械设计工程师。机械设计是一项创造性的工作。设计工程师不仅在工作上要有创造性,还必须在机械制图、运动学、工程材料、材料力学和机械制造工艺学等方面具有深厚的基础知识。 如前所诉,机械设计的目的是生产能够满足人类需求的产品。发明、发现和科技知识本身并不一定能给人类带来好处,只有当它们被应用在产品上才能产生效益。因而,应该认识到在一个特定的产品进行设计之前,必须先确定人们是否需要这种产品。 应当把机械设计看成是机械设计人员运用创造性的才能进行产品设计、系统分析和制定产品的制造工艺学的一个良机。掌握工程基础知识要比熟记一些数据和公式更为重要。仅仅使用数据和公式是不足以在一个好的设计中做出所需的全部决定的。另一方面,应该认真精确的进行所有运算。例如,即使将一个小数点的位置放错,也会使正确的设计变成错误的。 新设计本身会有许多缺陷和未能预料的问题发生,只有当这些缺陷和问题被解决之后,才能体现出新产品的优越性。因此,一个性能优越的产品诞生的同时,也伴随着较高的风险。应该强调的是,如果设计本身不要求采用全新的方法,就没有必要仅仅为了变革的目的而采用新方法。 在设计的初始阶段,应该允许设计人员充分发挥创造性,不受各种约束。即使产生了许多不切实际的想法,也会在设计的早期,即绘制图纸之前被改正掉。只有这样,才不至于堵塞创新的思路。通常,要提出几套设计方案,然后加以比较。很有可能在最后选定的方案中,采用了某些未被接受的方案中的一些想法。心理学家经常谈论如何使人们适应他们所操作的机器。设计人员的基本职责是努力使机器来适应人们。这并不是一项容易的工作,因为实际上并不存在着一个对所有人来说都是最优的操作范围和操作过程。 另一个重要问题,设计工程师必须能够同其他有关人员进行交流和磋商。在开始阶段,设计人员必须就初步设计同管理人员进行交流和磋商,并得到批准。这一般是通过口头讨论,草图和文字材料进行的。为了进行有效的交流 ,需要解决下列问题: (1)所设计的这个产品是否真正为人们所需要? (2)此产品与其他公司的现有同类产品相比有无竞争能力?

毕业论文外文翻译模版

长江大学工程技术学院 毕业设计(论文)外文翻译 外 文 题 目 Matlab Based Interactive Simulation Program for 2D Multisegment Mechanical Systems 译 文 题 目 二维多段机械系统基于Matlab 的 交互式仿真程序 系 部 化学工程系 专 业 班 级 化工60801 学 生 姓 名 李泽辉 指 导 教 师 张 铭 辅 导 教 师 张 铭 完 成 日 期 2012.4.15 顶层配置在管路等,要求设备,所有设要求,对调整使案,编是指机确保机组中资料试

外文翻译 二维多段机械系统基于Matlab 的交互式仿真程序 Henryk Josiński, Adam ?witoński, Karol J?drasiak 著;李泽辉 译 摘要:本文介绍了多段机械系统设计原则,代表的是一个模型的一部分的设计系统,然后扩展 形成的几个部分和模型算法的分类与整合的过程,以及简化步骤的过程叫多段系统。本文还介绍了设计过程的二维多段机械系统的数字模型,和使用Matlab 的软件包来实现仿真。本文还讨论测试运行了一个实验,以及几种算法的计算,实现了每个单一步骤的整合。 1 简介 科学家创造了物理模型和数学模型来表示人类在运动中的各种形式。数学模型 使创建数字模型和进行计算机仿真成为可能。模型试验,可以使人们不必真正的实 验就可以虚拟的进行力和力矩的分解。 本文研究的目的是建立一个简单的多段运动模型,以增加模型的连续性和如何 避免不连续为原则。这是创建一个人类运动模型系统的冰山一角。其使用matlab 程 序包创建的数字模型,可以仿真人类运动。 文献中关于这一主题的内容很广泛。运动的模式和力矩的分解在这些文献中都 有涉猎。动态的平面人体运动模型,提出了解决了迭代矩阵的方法。还值得一提的 是这类项目的参考书目,布鲁贝克等人提出了一个模型——人腿模型,这个以人的 物理运动为基础的平面模型仿真了人腿——一个单一的扭簧和冲击碰撞模型。人腿 模型虽然简单,但是它展示人类的步态在水平地面上的运动特征。布鲁贝克等人还 介绍,在人腿模型的双足行走的基础上,从生物力学的角度而言,符合人体步行的 特征。这个模型具有一个躯干,双腿膝盖和脚踝。它能够合理的表现出人多样的步 态风格。一个仿真人类运动的数学模型反应出了人的部分运动状态。 图1. 力的分解 2 力的分解

毕业设计英文文献翻译

青岛大学 毕业论文(设计)科技文献翻译 院系:自动化工程学院控制工程系 专业:自动化 班级:2009级4班 姓名:史发涛 指导教师:于金鹏 2013年4月10日

Providing Integrated Condition Monitoring Solutions for World Class Performance Rockwell Automation is a premier provider of Integrated Condition Monitoring Solutions (ICMS) to all major industry segments. Offering the latest state-of-the art technology in vibration analysis, oil analysis, on-line surveillance and protection systems,remote monitoring, as well as outstanding training and customer support services. Through strategic alliances with major Computerized Maintenance Management Systems (CMMS) providers Rockwell Automation can now provide integrated systems that provide critical machinery information throughout the enterprise. Portable Systems Enpac The Enpac? is a Windows CE based 2-channel high performance data collector and signal analyzer. The Enpac? collects field data, includi ng vibration information and process variables. Enpac? allows easy condition monitoring of equipment found in many process industries such as power generation, petrochemical, pulp and paper, and primary metals.The Enpac? features a built in optical (laser) tachometer, a choice of either a 1/8 or 1/4 VGA resolution screen, ability to store data on standard Type I or Type II PCMCIA cards and on-line contextsensitive HELP, built in to all applications. Online Systems Rockwell Automation offers a complete range of online hardware and software systems designed to meet your machinery protection and condition monitoring needs. When you need to protect your critical machinery assets the 6600 Series machinery protection system provides continuous monitoring. The Enw atch? Online Surveillance System is a cost-effective solution for monitoring the condition of the important machines in your plant.The 6600 Series and Enwatch? systems can be integrated seamlessly with Emonitor Odyssey?or Enshare? machinery information software. This integrated solution will provide you with a complete picture of the condition of your plant. Entrx When you need to understand how your rotating machinery is performing then Entrx is the professional’s tool. Entrx provides the means for reliable and consistent data acquisition for your entire steady state and transient machine operating modes. Entrx data acquisition hardware is fully configurable by the user and is capable of collecting data in both multiplexed and simultaneous / continuous modes. Graphical presentations of your machinery help to provide a visual display of what is happening to your machinery.

机械设计外文翻译中英文

. 机械设计理论机械设计是一门通过设计新产品或者改进老产品来满足人 类需求的应用技术科形状和详细结构的基本主要研究产品的尺寸、学。它涉及工程技术的各个领域,构思,还要研究产品在制造、销售和使用等方面的问题。机械设进行各种机械设计工作的人员通常被称为设计人员或者机械设计工程师。还必须在机械制设计工程师不仅在工作上要有创造性,计是一项创造性的工作。材料力学和机械制造工艺学等方面具有深厚的基础知识。工程材料、图、运动学、发现和科技机械设计的目的是生产能够满足人类需求的产品。发明、如前所诉,知识本身并不一定能给人类带来好处,只有当它们被应用在产品上才能产生效必须先确定人们是否需因而,应该认识到在一个特定的产品进行设计之前,益。要这种产品。系统分析应当把机械设计看成是机械设计人员运用创造性的才能进行产品设计、掌握工程基础知识要比熟记一些数据和公和制定产品的制造工艺学的一个良机。仅仅使用数据和公式是不足以在一个好的设计中做出所需的全部决式更为重要。定的。另一方面,应该认真精确的进行所有运算。例如,即使将一个小数点的位置放错,也会使正确的设计变成错误的。当新的方而且愿意承担一定的风险,一个好的设计人员应该勇于提出新的想法,所花费法不适用时,就使用原来的方法。因此,设计人员必须要有耐心,因为为要求屏弃许多陈旧的,的时间和努力并不能保证带来成功。一个全新的设计,一位机由于许多人墨守成规,这样做并不是一件容易的事。人们所熟知的方法。在此过程中应该认真选择原有械设计师应该不断地探索改进现有的产品的方法,的、经过验证的设计原理,将其与未经过验证的新观念结合起来。只有当这些缺陷和问题被解决新设计本身会有许多缺陷和未能预料的问题发生,之后,才能体现出新产品的优越性。因此,一个性能优越的产品诞生的同时,也就没如果设计本身不要求采用全新的方法,伴随着较高的风险。应该强调的是,有必要仅仅为了变革的目的而采用新方法。即使产不受各种约束。应该允许设计人员充分发挥创造性,在设计的初始阶段,只有也会在设计的早期,生了许多不切实际的想法,即绘制图纸之前被改正掉。这样,才不致于堵塞创新的思路。通常,要提出几套设计方案,然后加以比较。很有可能在最后选定的方案中,采用了某些未被接受的方案中的一些想法。 .. . 设计人员的基本职责是努心理学家经常谈论如何使人们适应他们所操作的机器。因为实际上并不存在着一个对力使机器来适应人们。这并不是一项容易的工作,所有人来说都是最优的操作范围和操作过程。在开始另一个重要问题,设计工程师必须能够同其他有关人员进行交流和磋商。这一并得到批准。阶段,设计人员必须就初步设计同管理人员进行交流和磋商,,需要解决般是通过口头讨论,草图和文字材料进行的。为了进行有效的交流下列问题:)所设计的这个产品